X-ray tube head

An X-ray tube and X-ray technology, which is applied in the field of X-ray tube head, can solve the problems such as setting the whole lead shielding plate on the side of the X-ray tube sleeve, reducing the heat capacity of the X-ray tube head, and affecting the volume of the X-ray tube sleeve. Achieve the effect of reducing clinical risk, increasing heat capacity and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

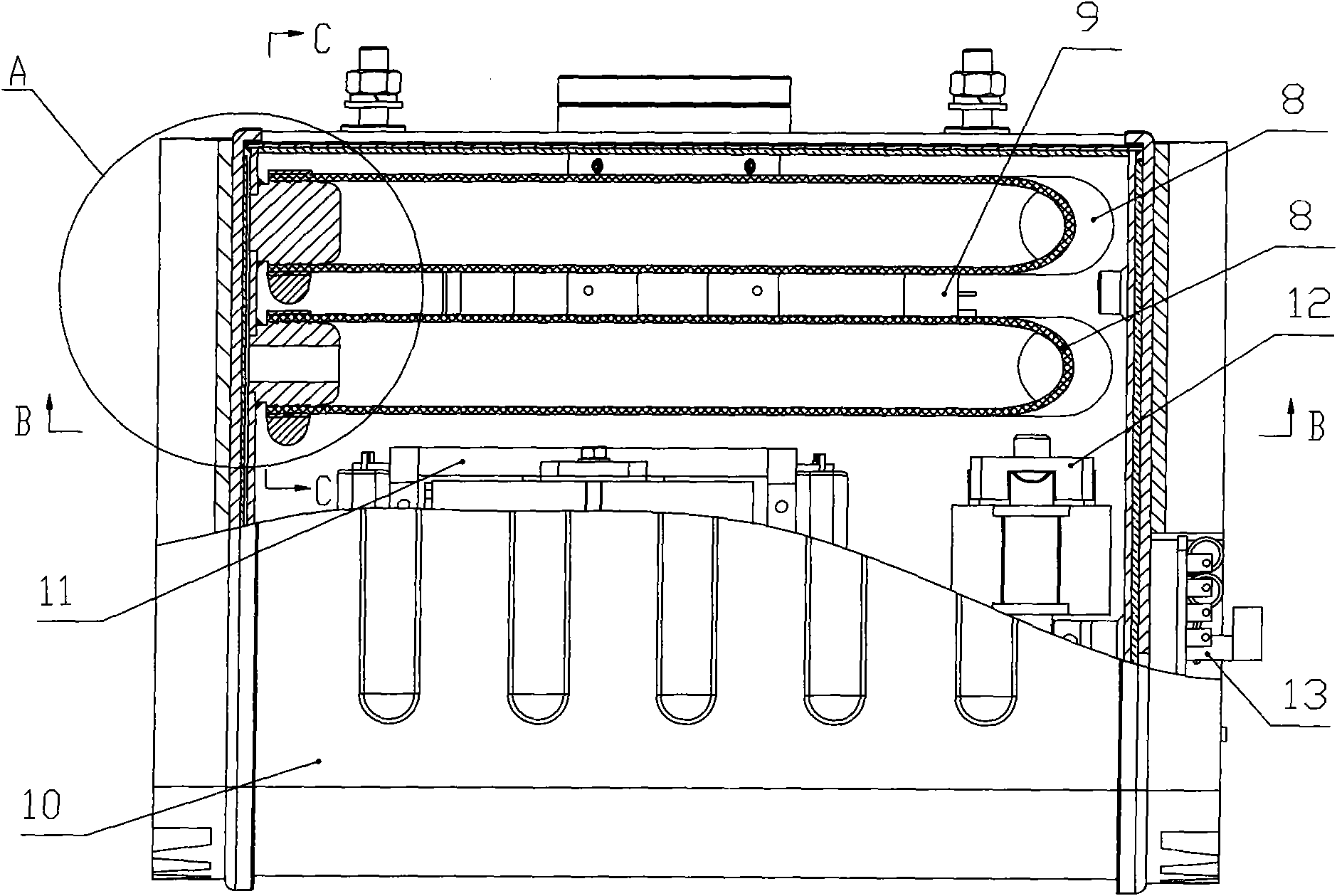

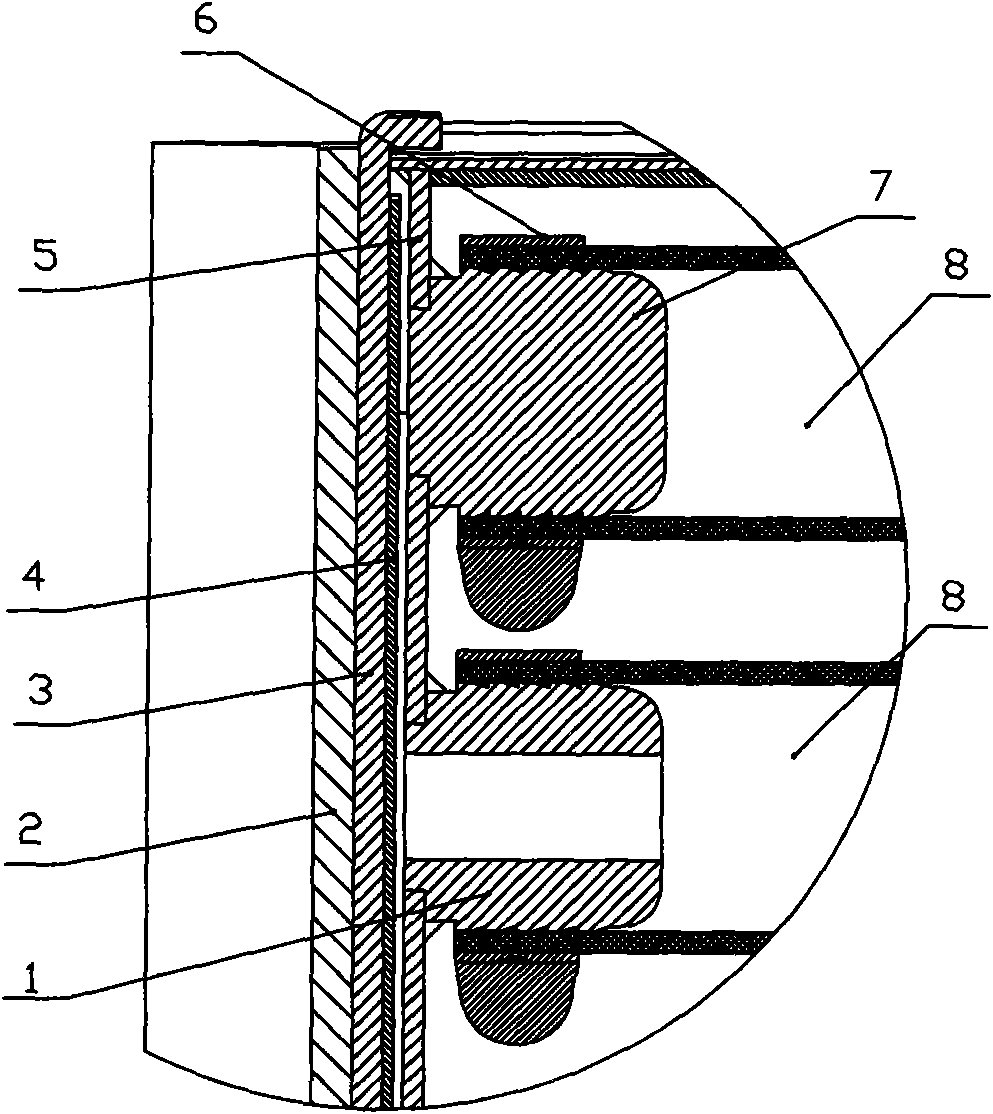

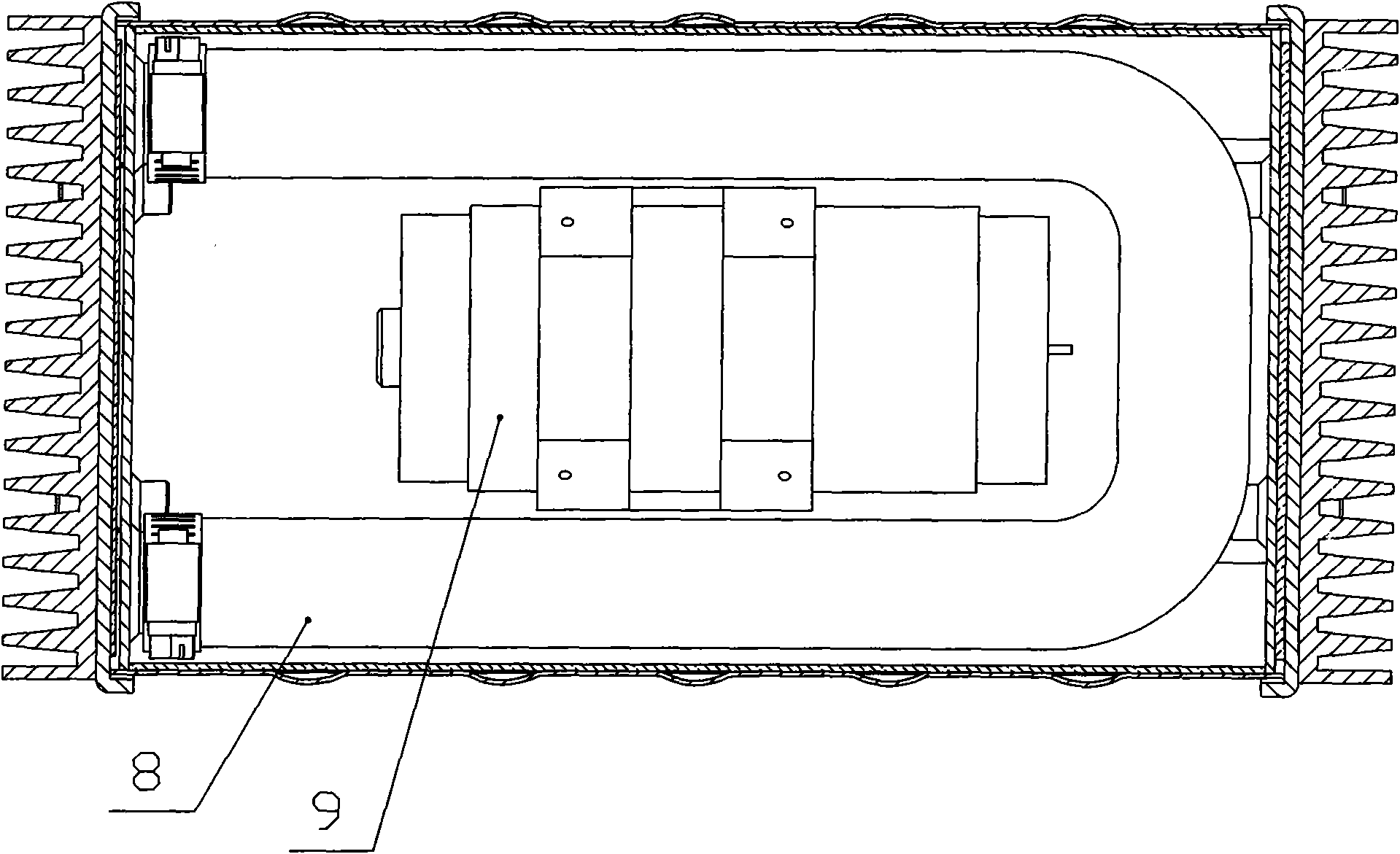

[0015] Such as Figure 1 to Figure 4 An embodiment given is an X-ray tube head, which is composed of an X-ray tube casing 10, a high-voltage transformer assembly 11, a filament transformer assembly 12, an X-ray tube 9, and an electrical interface 13. In the X-ray tube Two U-shaped expansion tubes 8 are installed inside the casing 10, and the two ends of the U-shaped expansion tubes 8 are respectively fixed on the expansion tube air guide plunger 1 and the expansion tube plunger 7 by expansion tube fixing hoops 6. The expansion tube gas guide plunger 1 and the expansion tube plunger 7 are welded on the side plate 5 of the X-ray tube cover, and the side plate 5 of the X-ray tube cover is fixed on the side plate 5 of the X-ray tube cover. A lead shielding plate 3 is inlaid inside the casing side shield 5 , and an aluminum radiator 2 is covered on the outside of the X-ray tube casing side shield 5 .

[0016] Since the X-ray tube jacket 1 is filled with transformer oil, when a loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com