Rear axle assembly of four-wheel motor cycle

A technology for motorcycles and rear axles, which is applied to axles, wheels, and vehicle components. It can solve the problems of high welding precision of locking lugs, high manufacturing cost of flat fork liners, abnormal noise of brake eccentric wear, etc., and achieve material saving. , simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

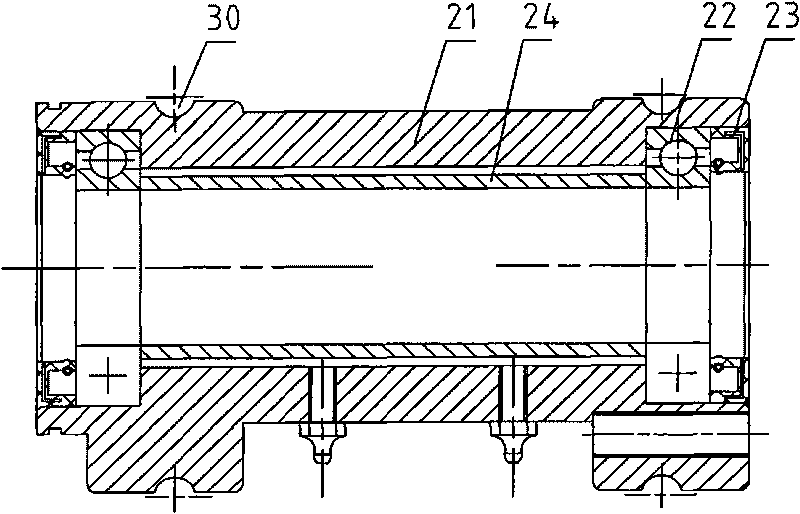

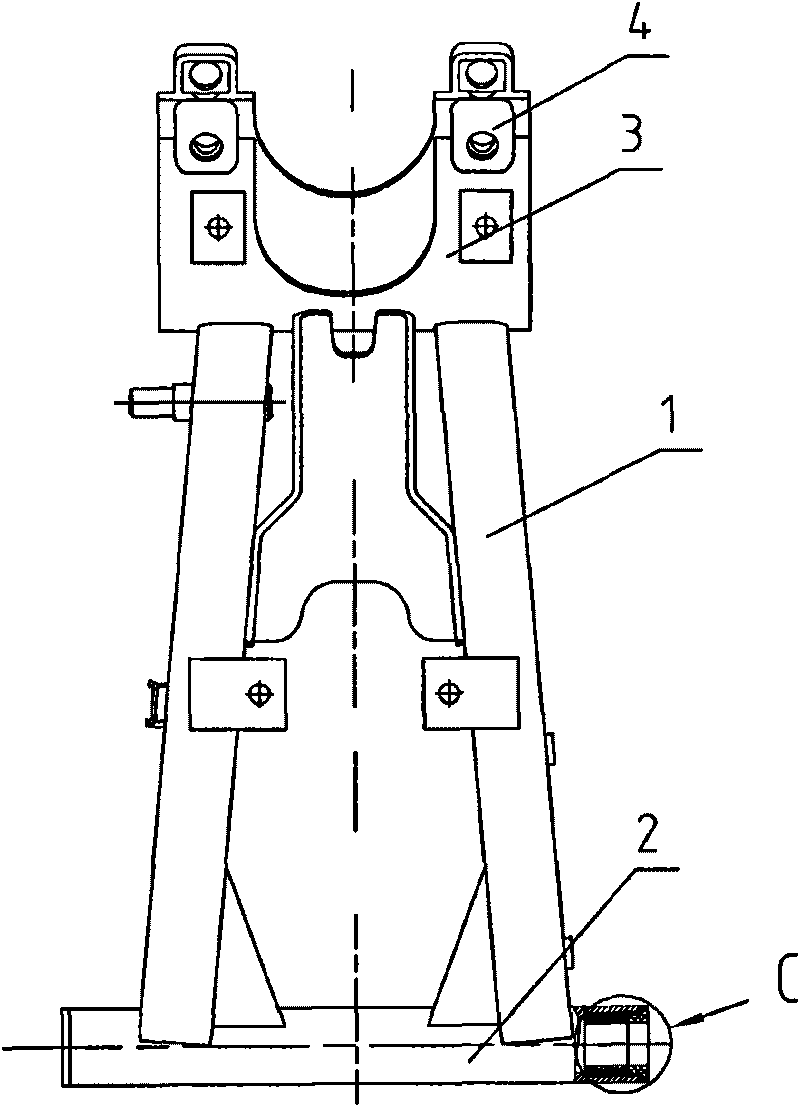

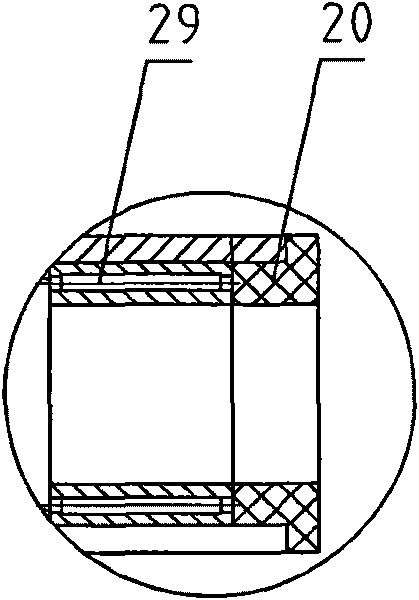

[0036] see Figure 4 , four-wheeled motorcycle rear axle assembly of the present invention, it comprises flat fork, rear axle housing 5, rear axle 15, rear disc brake disc seat 16, rear disc brake support 8 and chain wheel seat 17. The flat fork includes two flat fork side tubes 1, a flat fork shaft tube 2 welded to the two ends of the two flat fork side tubes and a flat fork hoop 3 (see Figure 5 ). The rear axle housing 5 is located in the flat fork hoop 3 and is tightly held by the flat fork hoop. See Figure 5 , Image 6 and Figure 7 , the flat fork hoop 3 is changed from the original steel plate to the circular steel pipe by the molding machine and is processed in the axial direction on the circular steel pipe to have a pull-through gap for adjusting the degree of tightness. The flat fork hoop 3 is provided with two pairs of locking lugs 4, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com