Intercepting flashboard

A shut-off ram and heat-resistant steel technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of short life, inability to withstand high temperature, poor use of the shut-off ram, etc., and achieve low expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Such as figure 1 The cut-off ram shown is made of heat-resistant steel, and the components and elements in the heat-resistant steel are calculated by mass percentage: Cr 15-30%; Ni 65-81%; C 0.15-0.25%; S 0.001- 0.03%; Si 0.2-1.5%; P 0.001-0.05%; Mn 0.5-1.0%; Mo 0.6-0.9%; V 0.2-0.4%; Cu 0.5%. Satisfied that the cut-off ram can withstand high temperature above 1200°C, and has a low expansion coefficient (18.0×10-6 / °C).

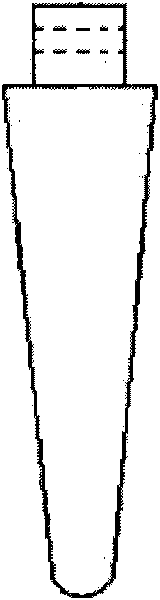

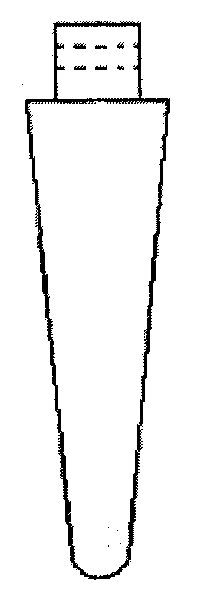

[0011] Such as figure 2 As shown, the thickness of the upper part of the closure ram is greater than that of the lower part, and the surface is inclined. The height of the ram is between 400-500mm, the width of the upper part of the ram is 60-70mm, and the width of the lower part of the ram is between 25-35mm. The board will not bend, deform or break under the environmental changes at room temperature and high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com