Belt cooling fixture for welding large-section aluminum conductor cable

An aluminum conductor, large-section technology, applied in cable/conductor manufacturing, circuit, connection, etc., can solve the problems of difficulty in ensuring the quality stability of cable welding process, difficulty in alignment of large-section conductors, and difficulty in welding, etc. The effect of plumpness, convenient welding operation and stable molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

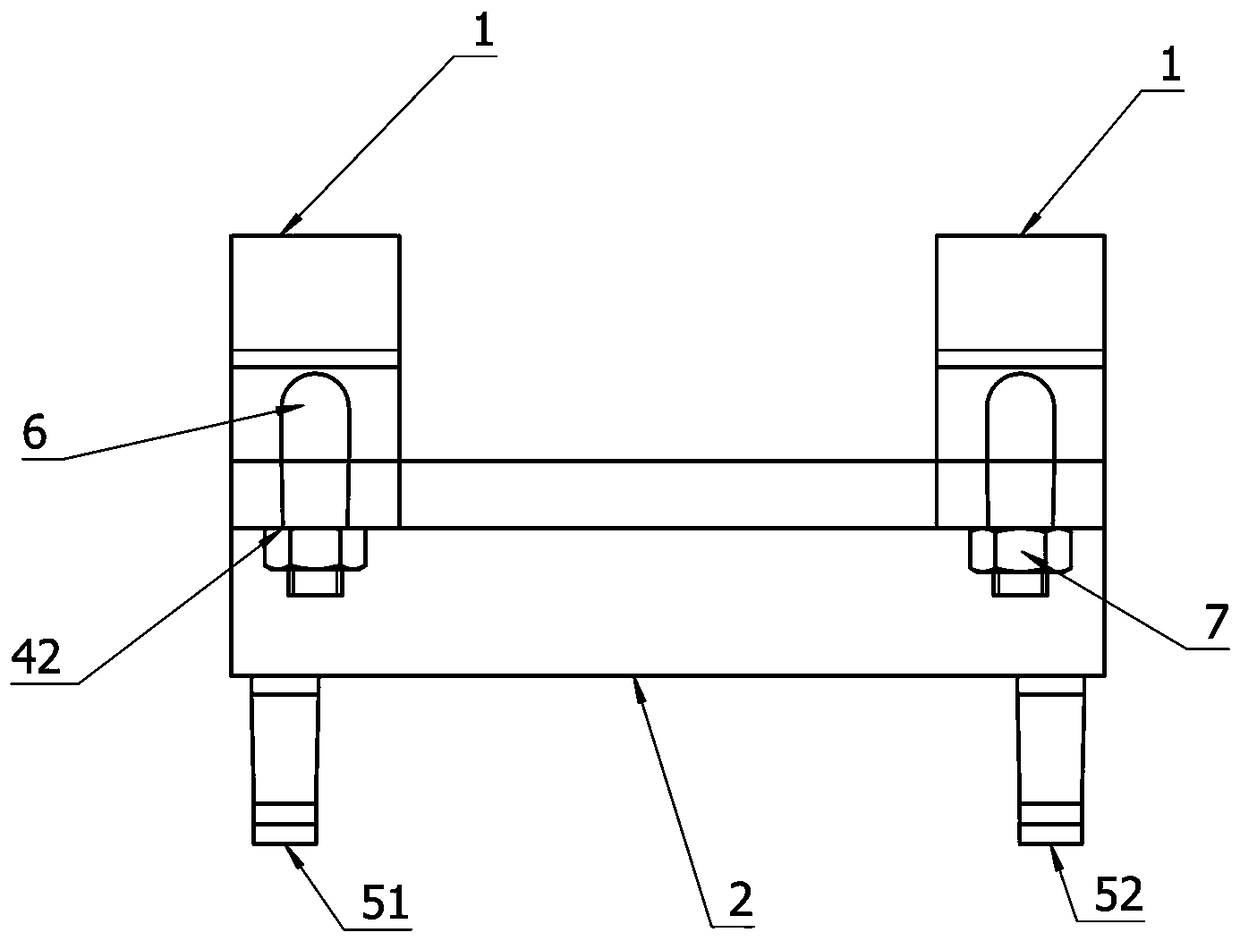

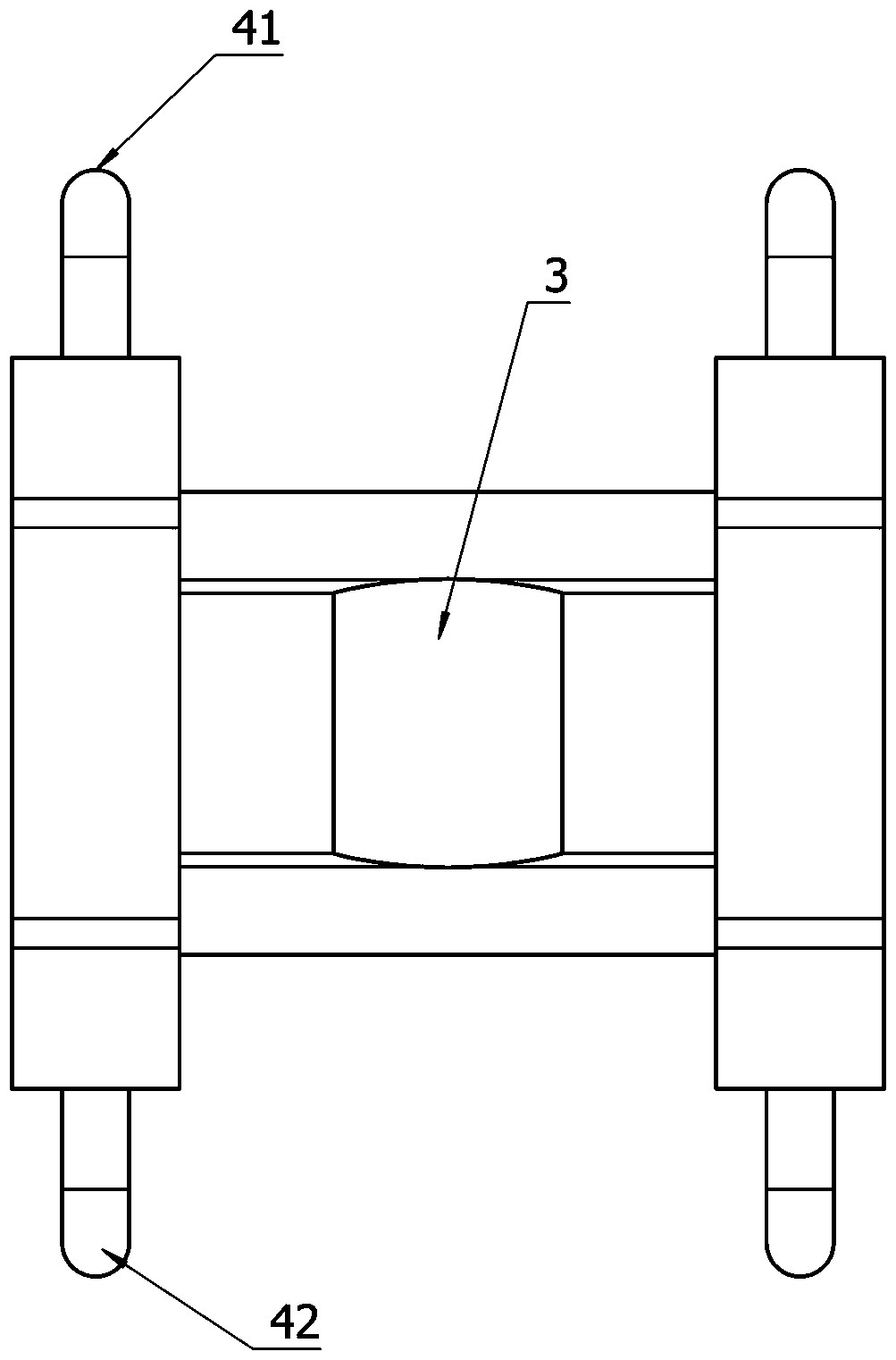

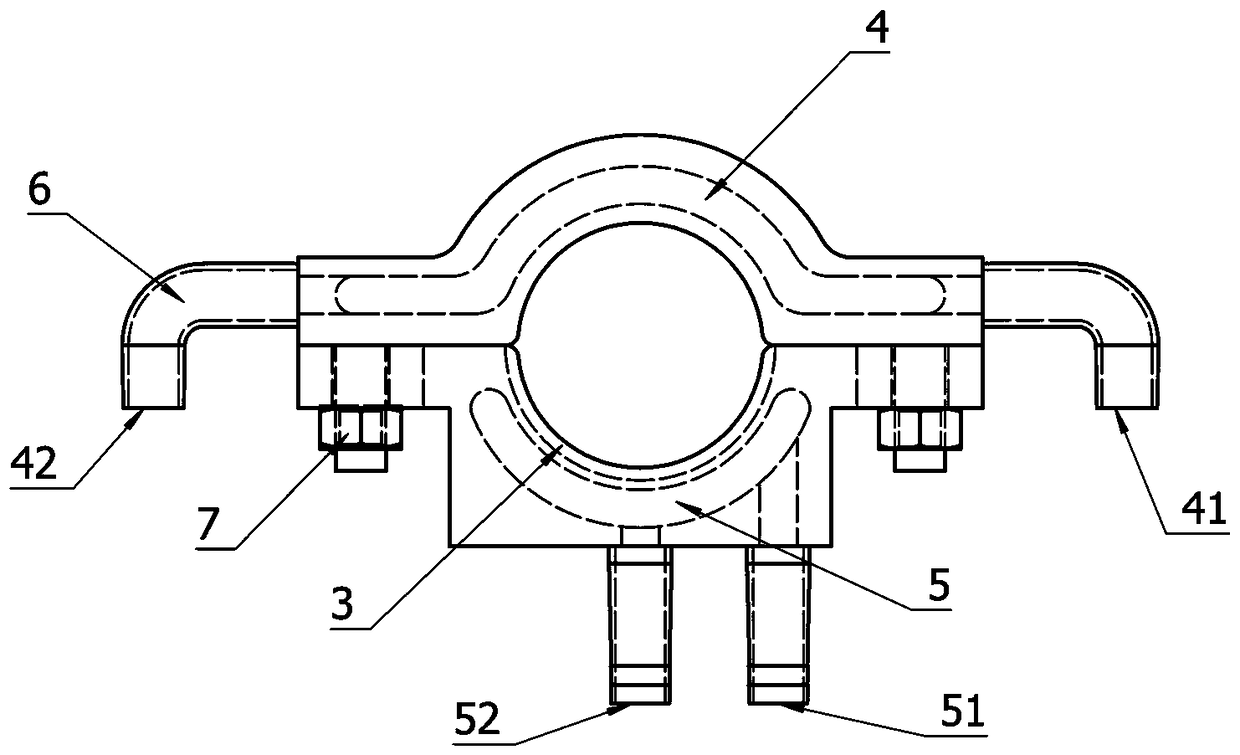

[0015] According to attached Figure 1~4 , the present invention is a cooling fixture for welding large-section aluminum conductor cables, including an upper fixture 1 and a lower fixture 2, the upper fixture 1 is a left part and a right part respectively provided with a semicircular arc groove, The lower fixture 2 is also provided with a semi-circular arc groove, and the left and right parts of the upper fixture 1 are respectively connected and fixed with the left and right ends of the lower fixture 2 through a screw and a fastening nut 7, and the screw is fixed At the bottom of the upper clamp 1, the lower clamp 2 is provided with a through hole matched with the screw rod. After fixing, the semi-circular arc-shaped grooves of the upper fixture 1 and the lower fixture 2 cooperate with each other, and the cross-section is a circle that matches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com