Water tank for heat pump water heater

A heat pump water heater and water tank technology, applied in the field of pressurized water tanks, can solve the problems of low volume utilization of water tanks, low energy efficiency of hot water machines, slow water convection, etc., and achieve the effects of reasonable structural design, average temperature, and increased heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

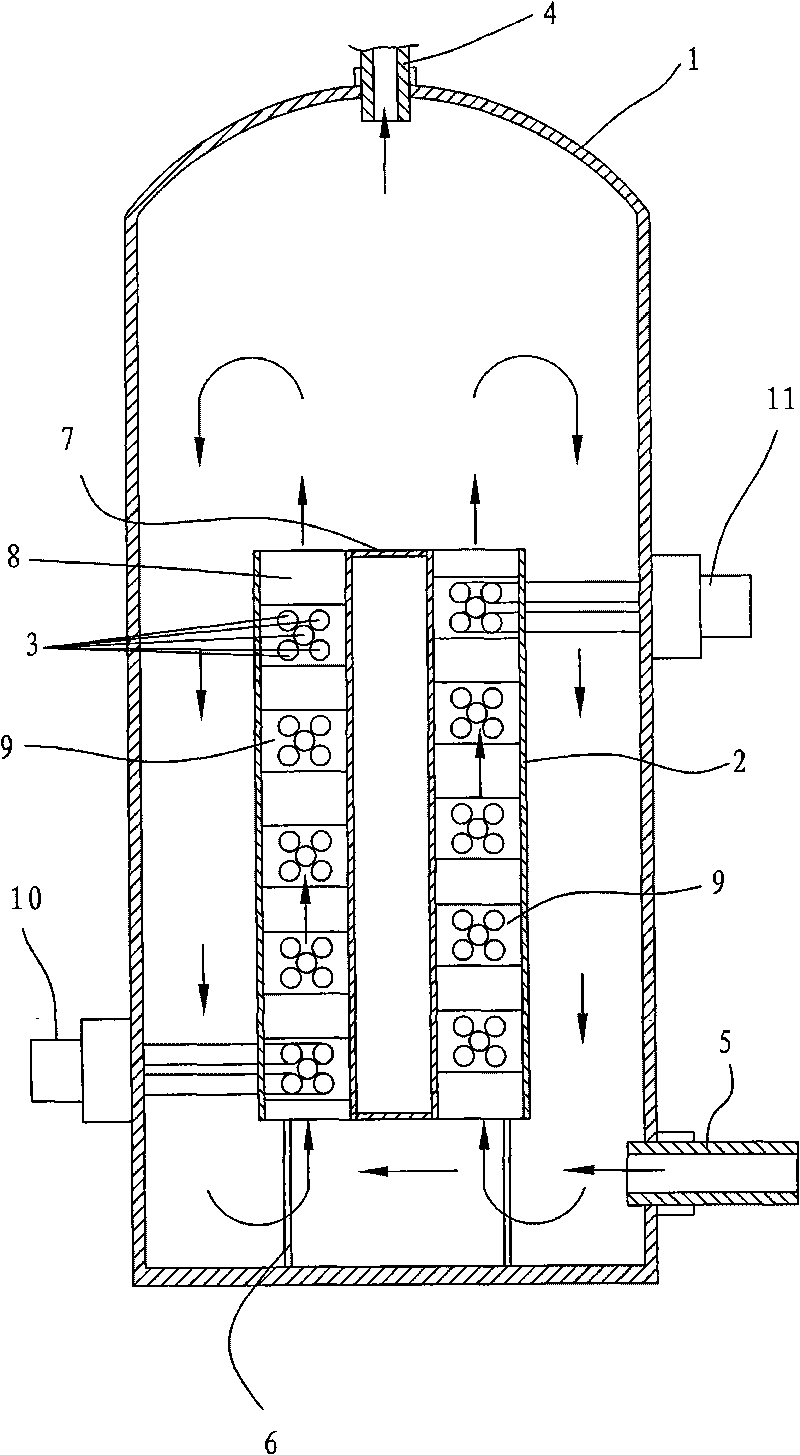

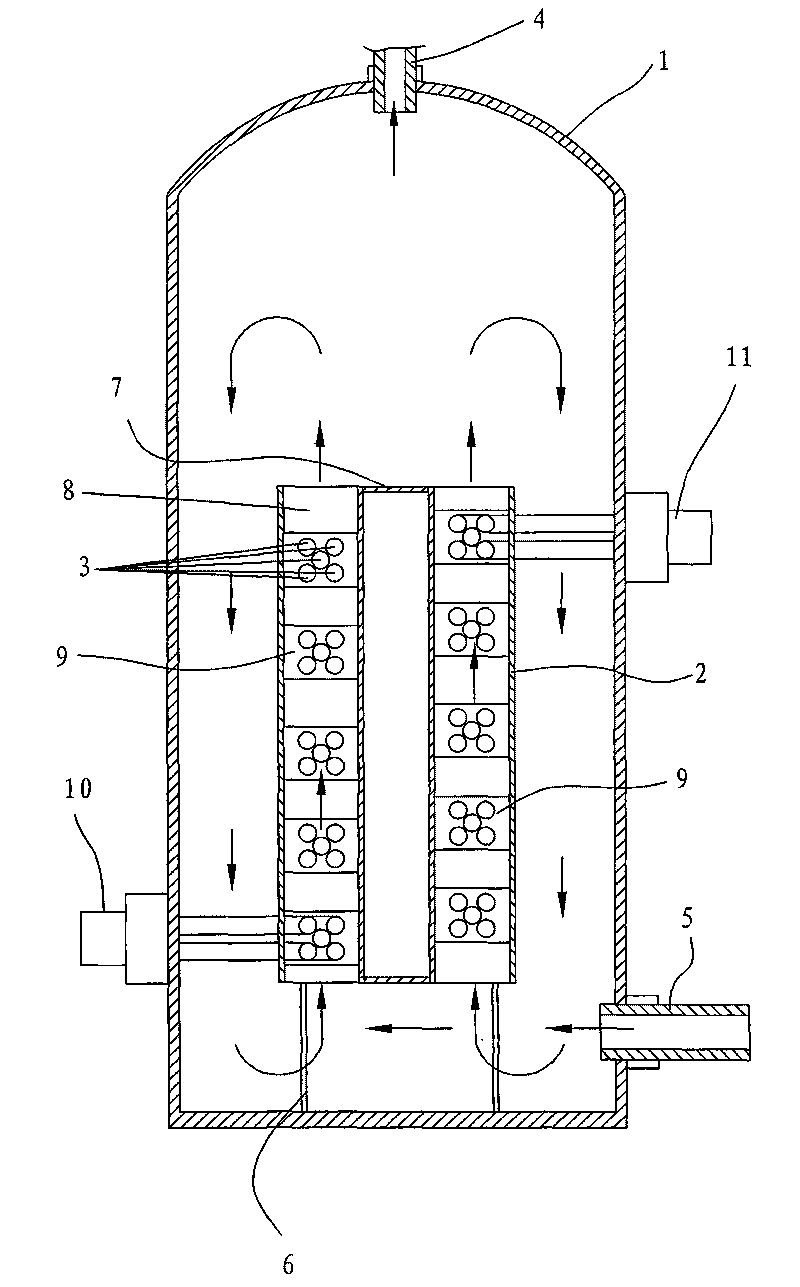

[0010] 1 and 2, a water tank for a heat pump water heater includes a tank 1, a cylinder 2 and five refrigerant tubes 3, the top of the tank 1 is provided with a water outlet 4, and the bottom of the tank is provided with a water inlet 5, The cylinder body 2 is set in the box body through the vertical column 6, the upper and lower ports of the cylinder body 2 are open, the lower port of the cylinder body is slightly higher than the water inlet of the box body, and the cylinder body body is provided with a cylinder body 7 along its axial direction. The gap 8 between the inner walls of the cylinder body 2 is provided with a plurality of positioning plates 9, the positioning plates 9 are vertically arranged in the gap 8, and are arranged spirally at intervals along the gap 8, and five refrigerant tubes 3 respectively pass through the positioning plates 9 and coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com