Method for generating standard torsional vibration signals

A signal generation and signal technology, which is applied in the field of power engineering, can solve the problems of inconvenient signal comparison for users and the inability to display torsional vibration signal parameters and waveforms online, and achieve the effects of friendly working interface, adjustable number of teeth, and stable signal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

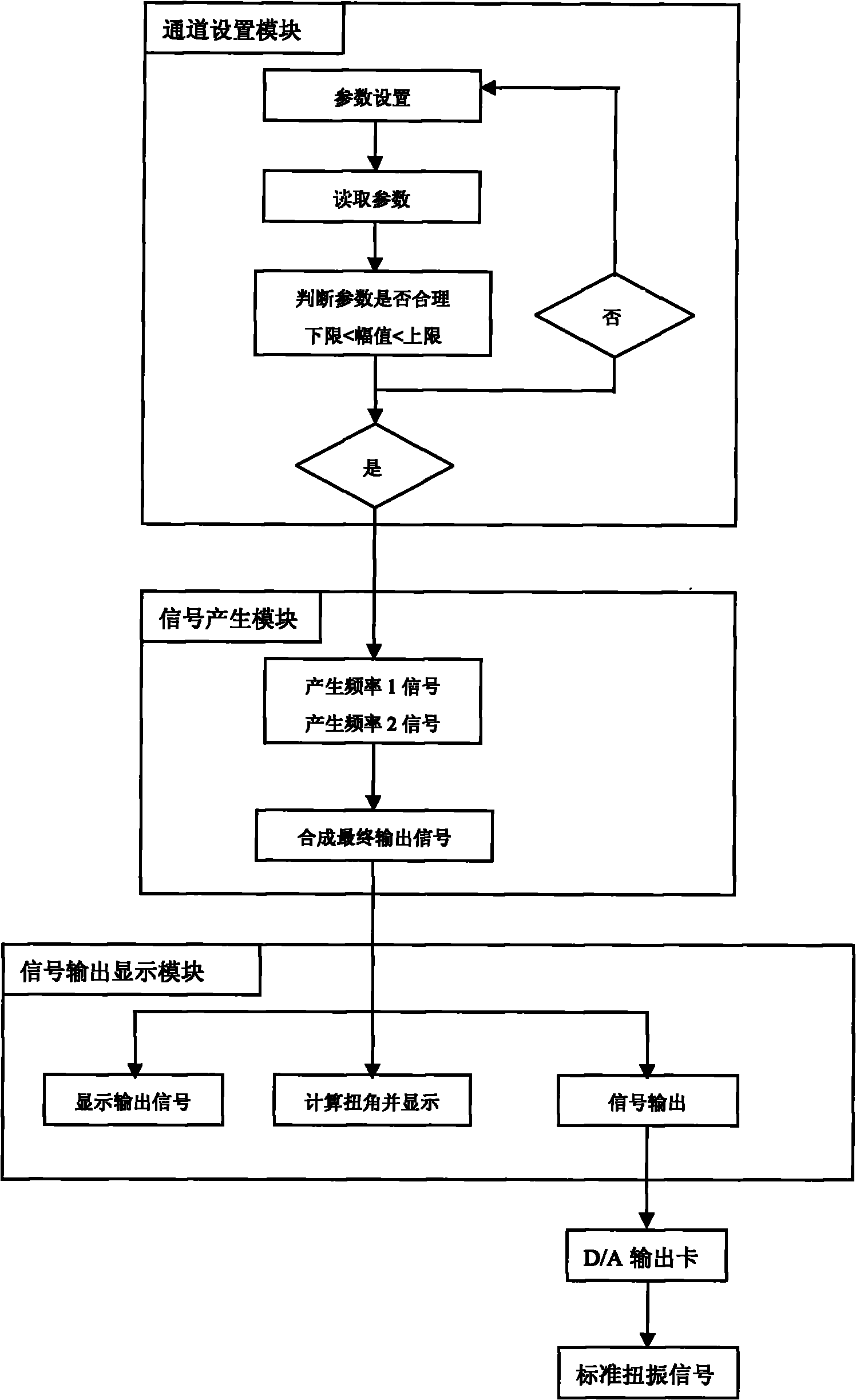

[0025] The invention is realized by a device composed of software composed of a parameter setting module, a signal generating module, a signal output display module and a D / A output card sequentially connected.

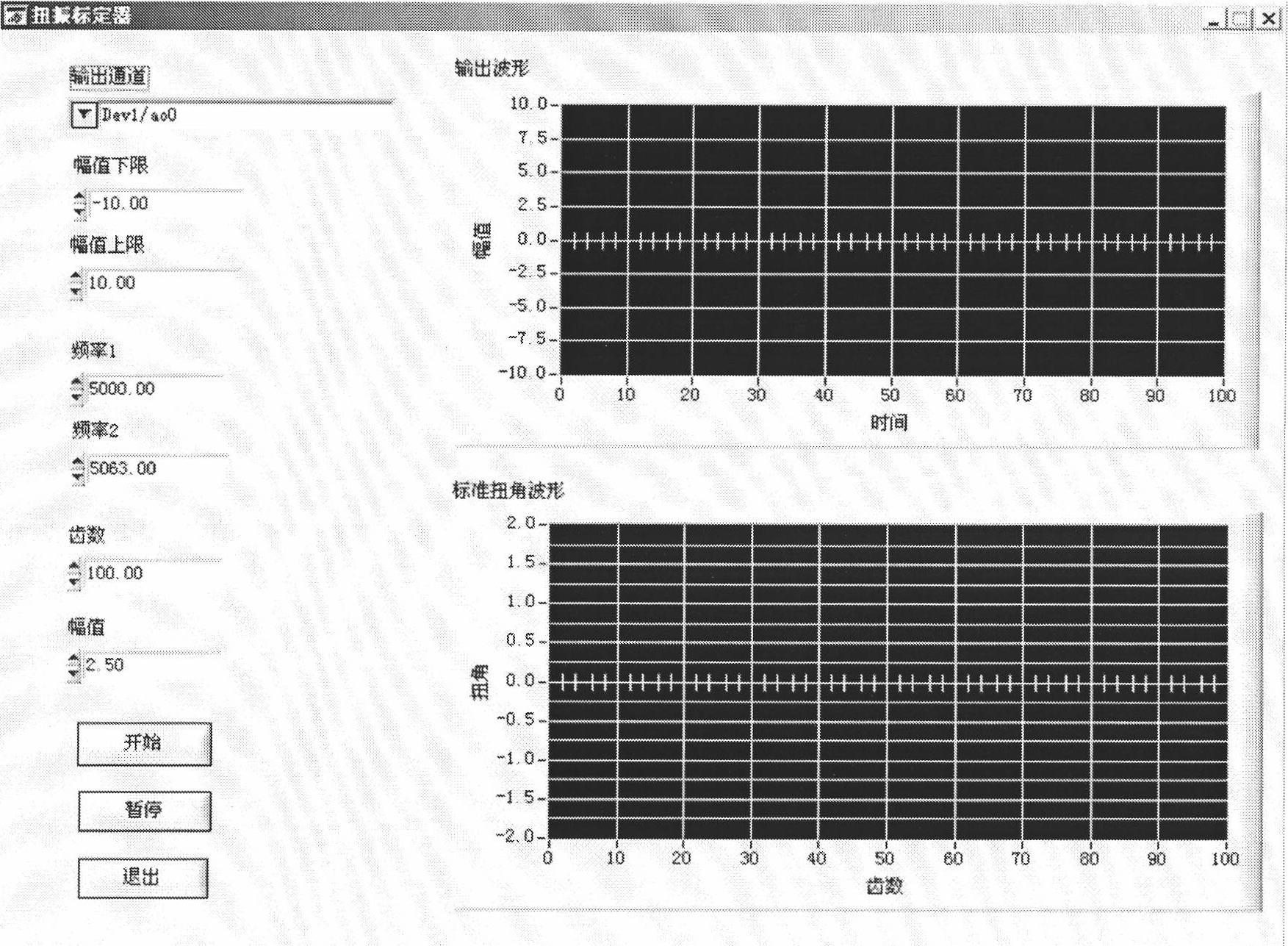

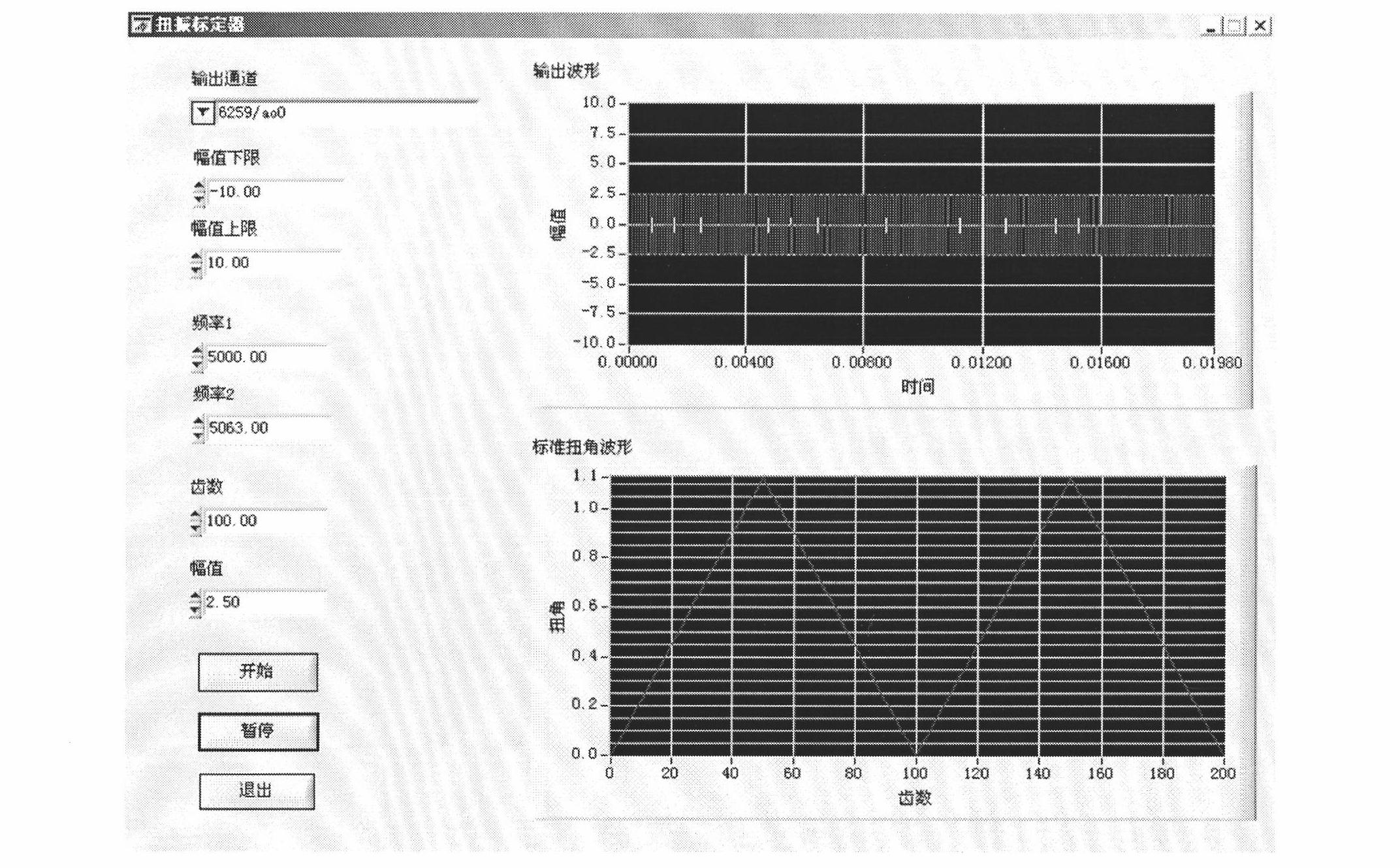

[0026] to combine figure 1 , set the following parameters in the parameter setting module: channel setting, tooth number setting, amplitude setting, frequency setting, voltage limit setting; channel setting is used to select the output channel of the D / A output card; tooth number setting can make the output standard torque The vibration signal is suitable for working conditions with different numbers of teeth; the amplitude setting can make the voltage amplitude of the output signal change as needed; the frequency setting is to set two different frequencies to simulate the actual torsional vibration signal; the voltage limit setting can protect The role of circuits and devices. After reading the above parameters, judge whether the parameter setting is reasonable, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com