Isolated optical fiber seal switching device and machining method thereof

A technology of a switching device and a processing method, which is applied to the coupling of optical waveguides and other directions, can solve problems such as the inability to meet the requirements of sealing timeliness, and achieve the effects of prolonging service life and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

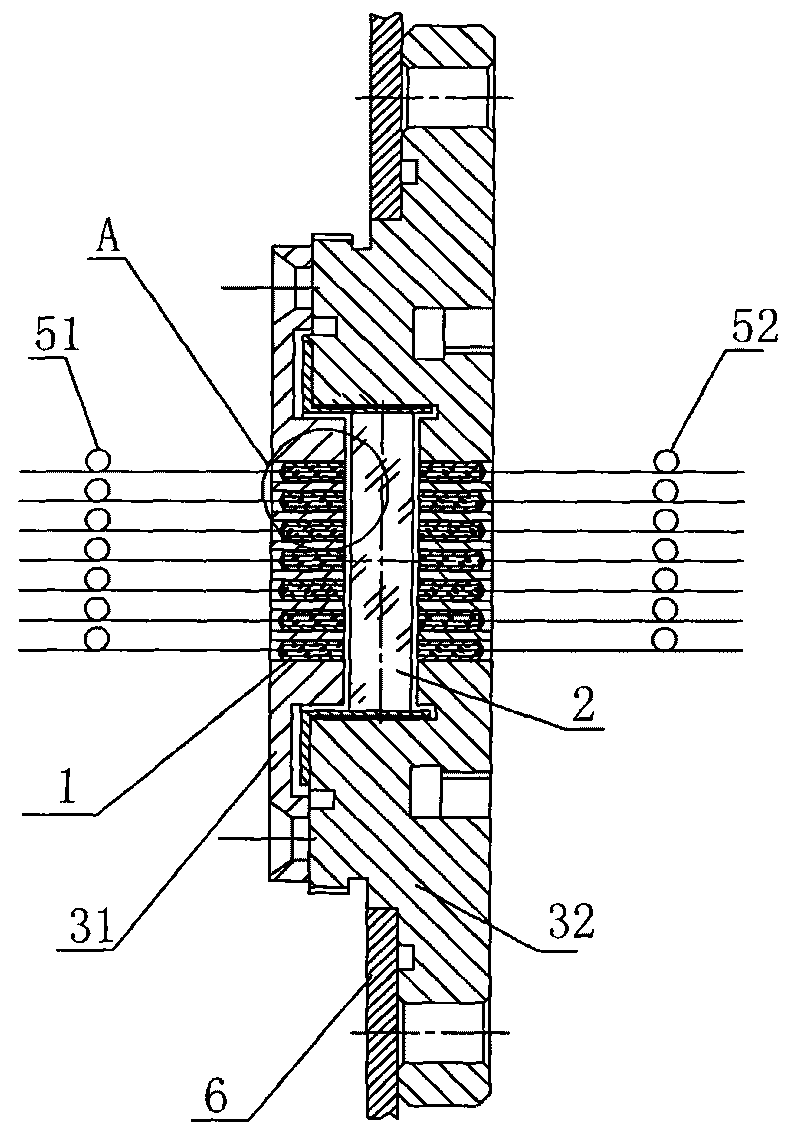

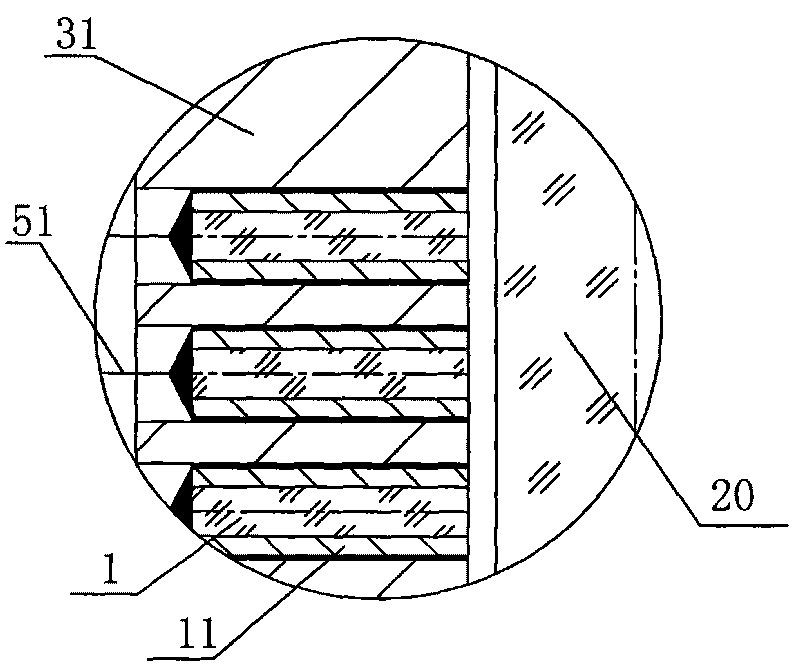

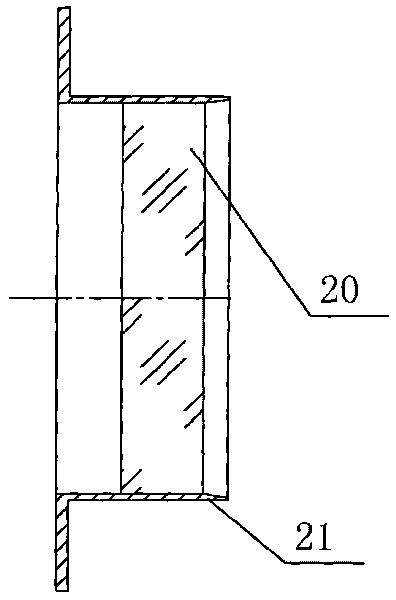

[0026] like Figure 1-Figure 5 As shown, the isolated optical fiber sealing transition device includes an inner flange 31, an outer flange 32 and a glass-metal sealing window 2, the glass-metal sealing window 2 is welded on the outer flange 32, and the inner flange 31 Fix the inner side of the container with the outer flange 32 and sandwich the glass-metal sealing window 2 between the two flanges, the outer flange 32 is used for sealing connection with the container interface from the outer side of the container; the inner flange 31 is provided with A plurality of collimator mounting holes 4, the outer flange 32 is provided with a corresponding number of collimator mounting holes 4 corresponding to one-to-one positions, each collimator mounting hole 4 is respectively fixed with a fiber collimator 1, The fiber collimator 1 on the inner flange 31 is used to transform the input optical signal into parallel light output, and the fiber collimator 1 on the outer flange 32 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com