Patents

Literature

45 results about "Glass-to-metal seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass-to-metal seals are a very important element of the construction of vacuum tubes, electric discharge tubes, incandescent light bulbs, glass encapsulated semiconductor diodes, reed switches, pressure tight glass windows in metal cases, and metal or ceramic packages of electronic components.

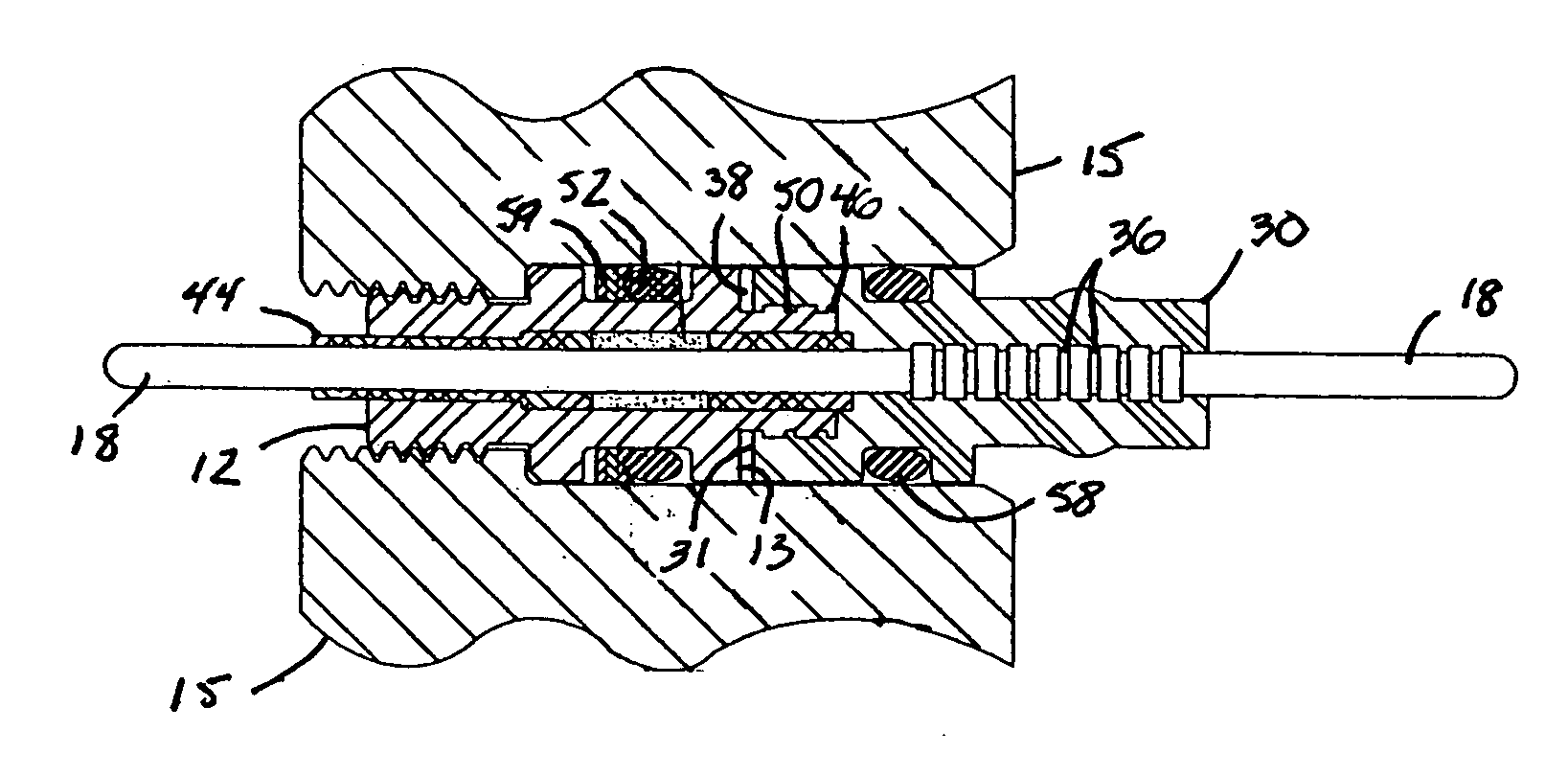

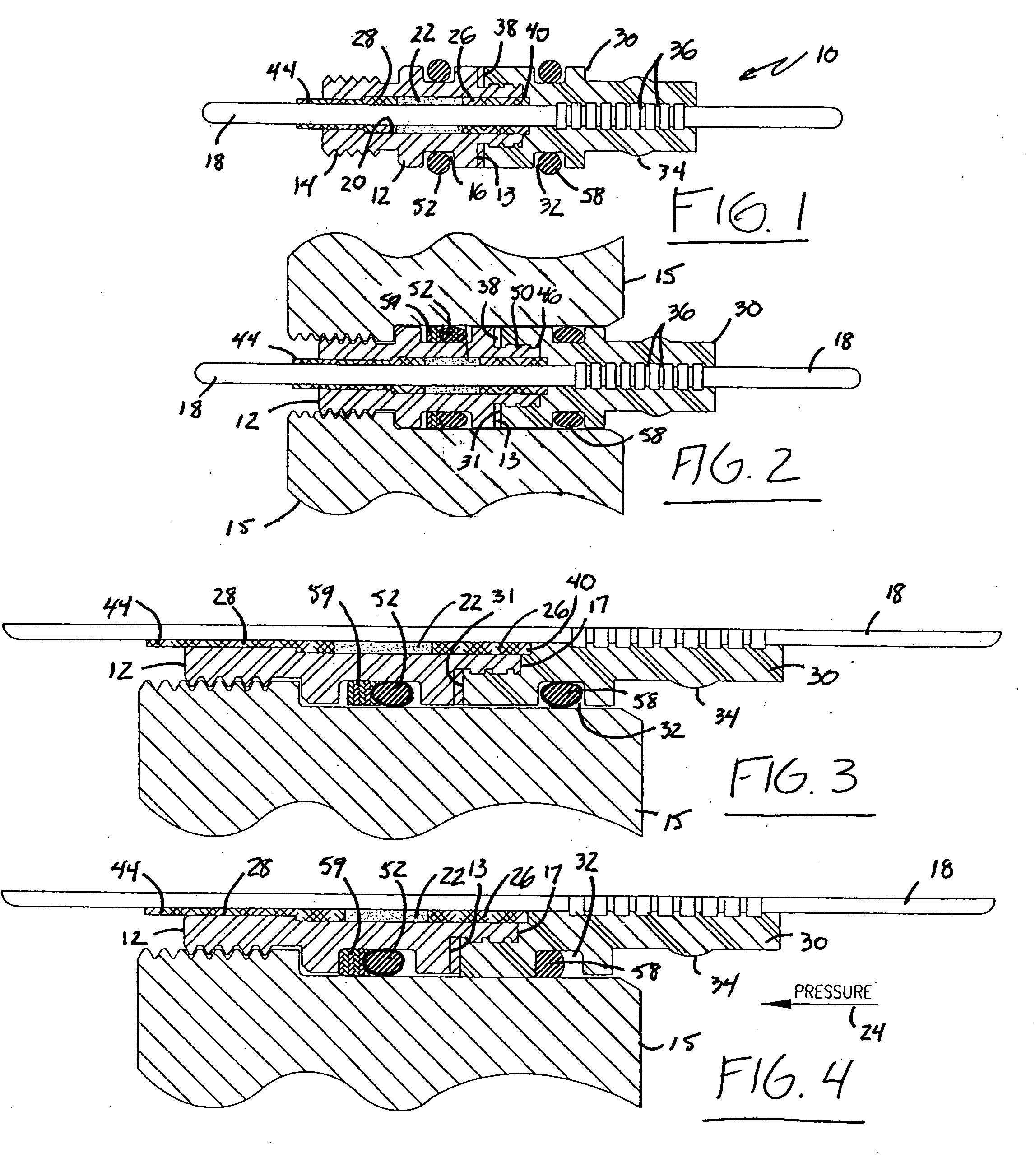

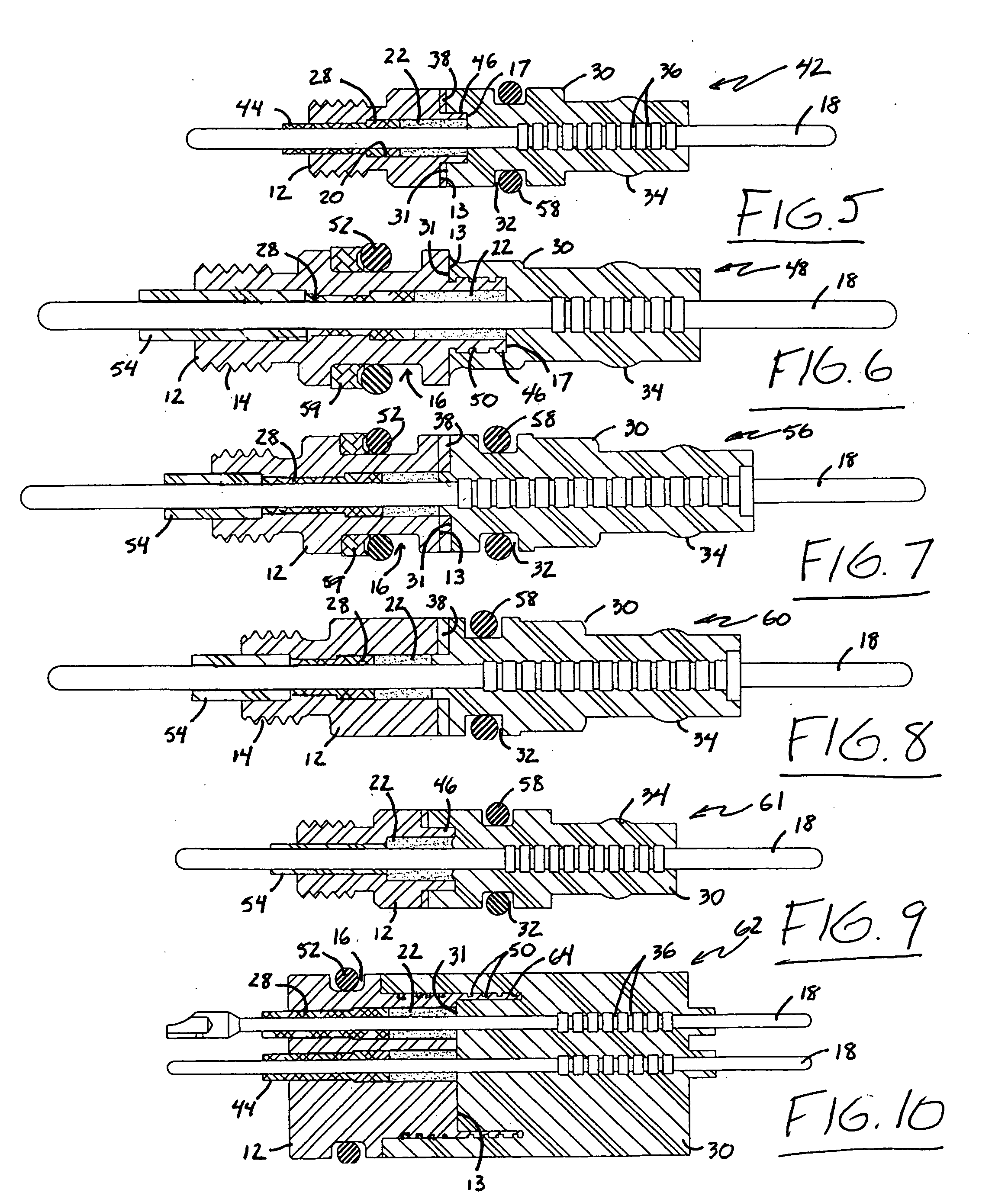

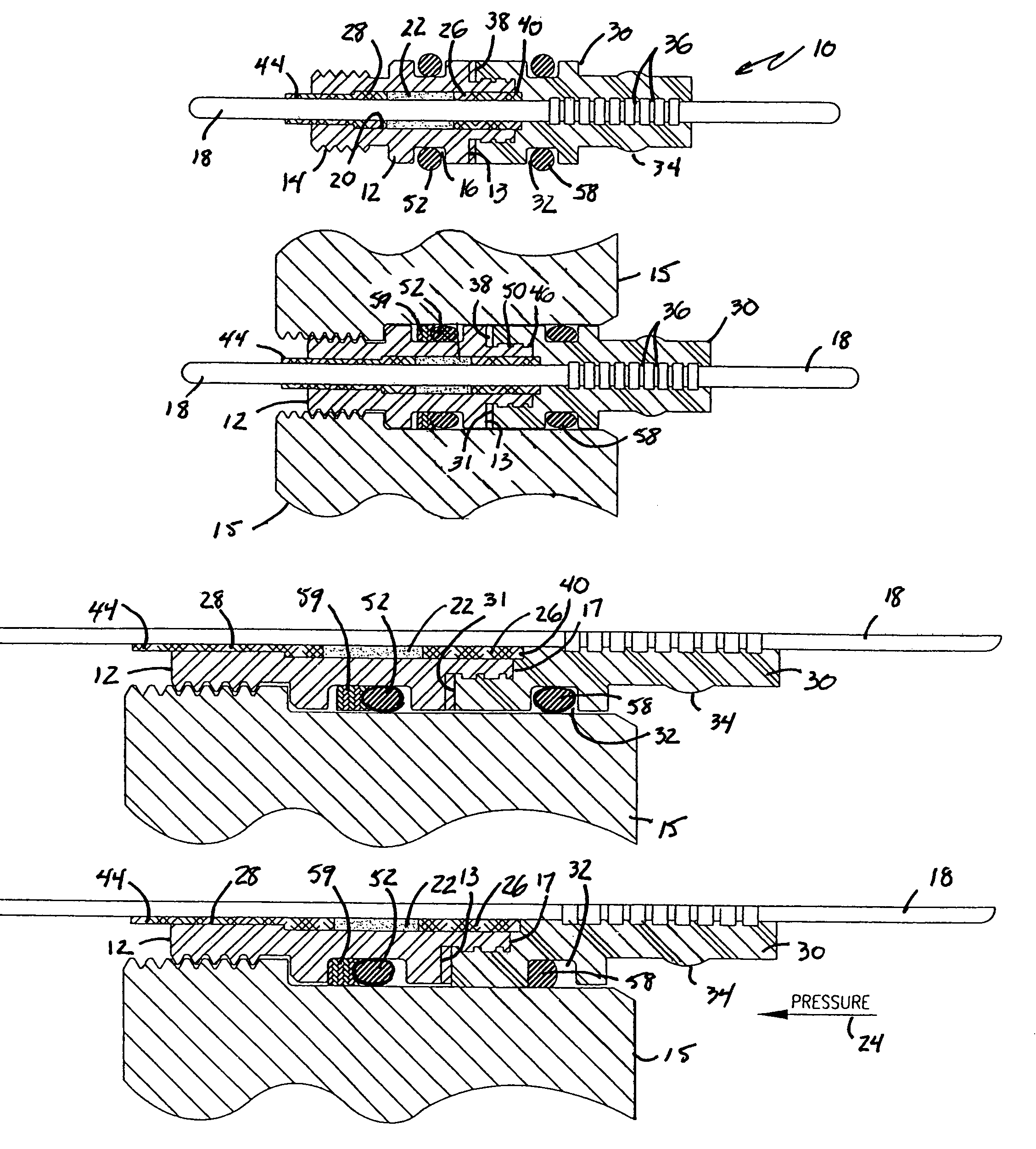

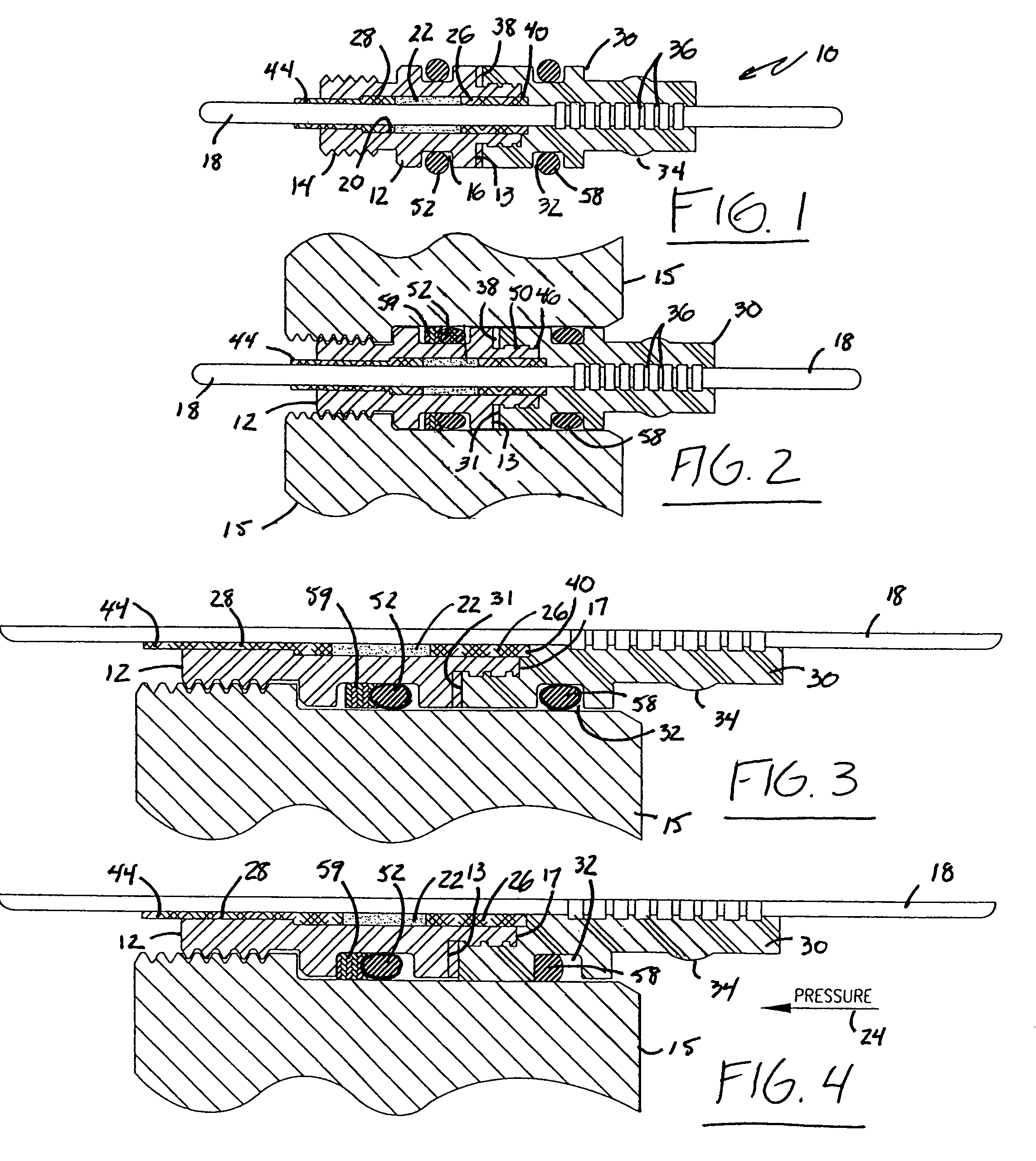

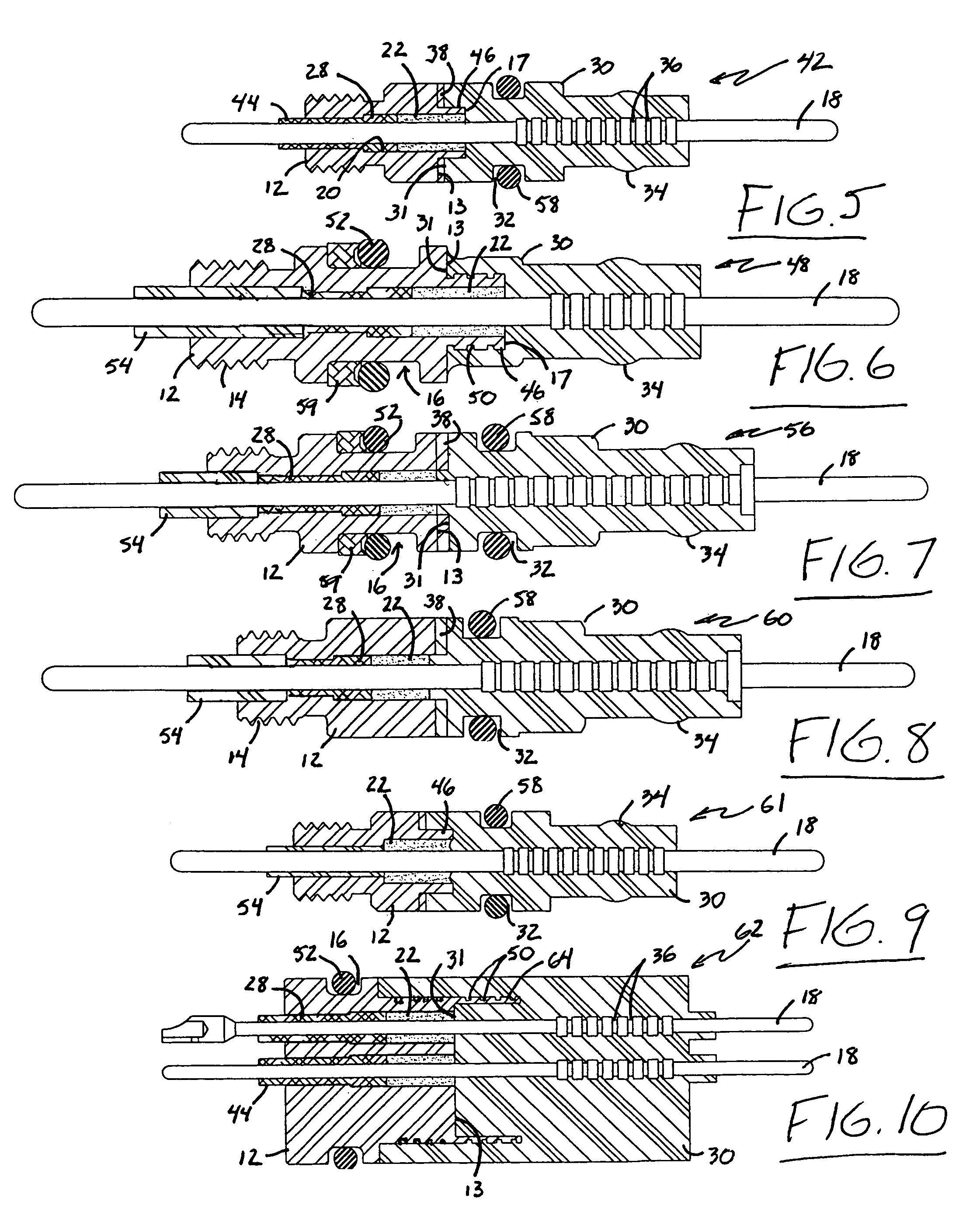

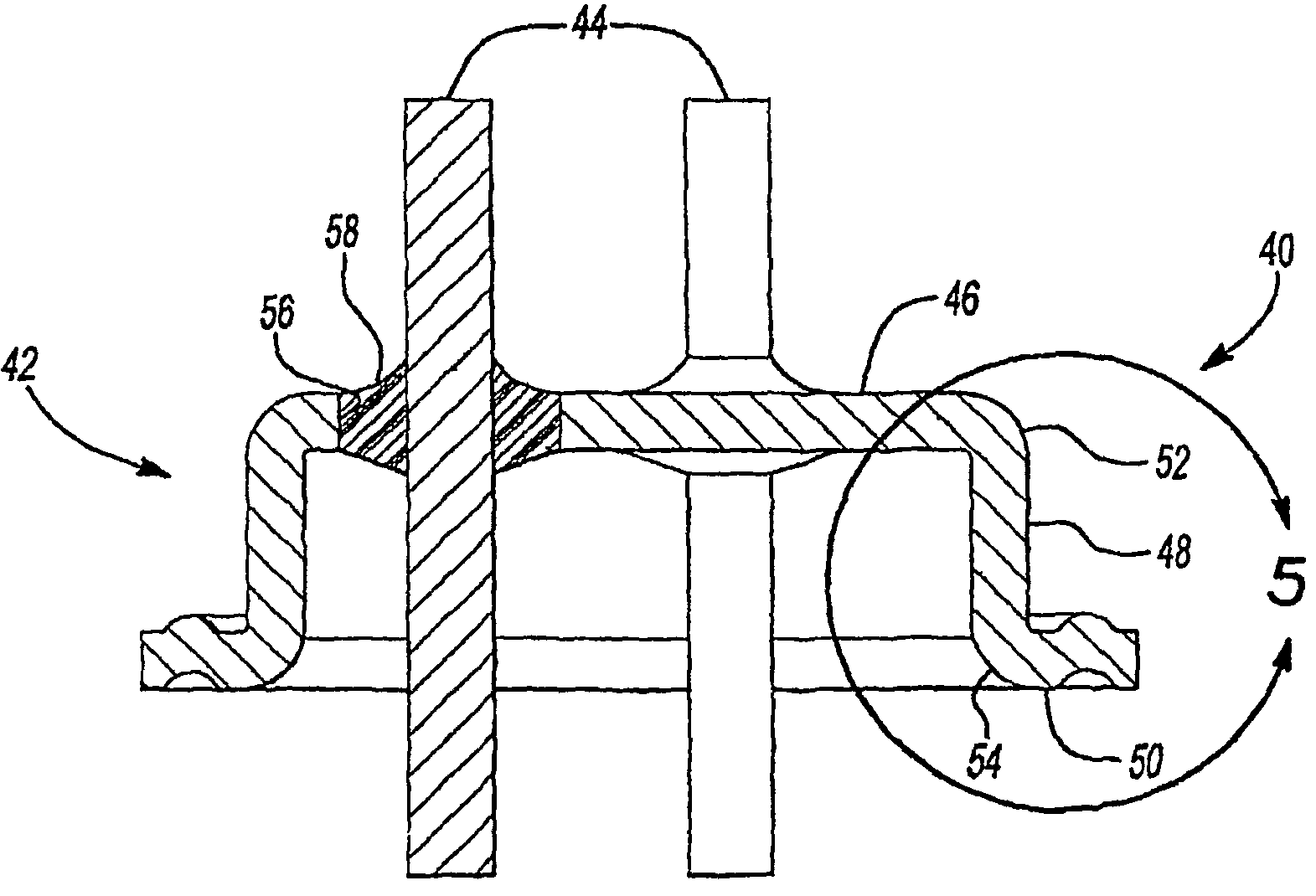

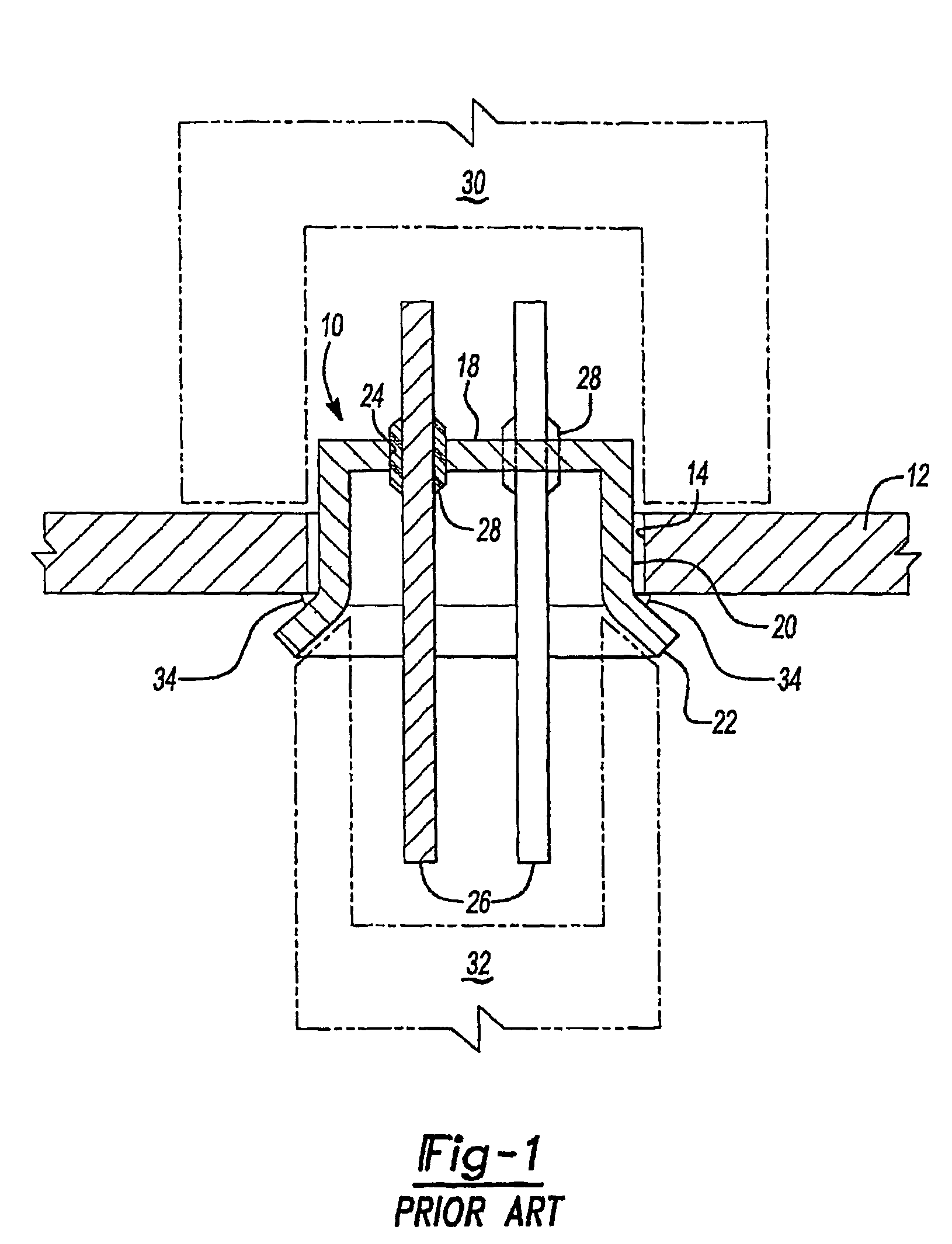

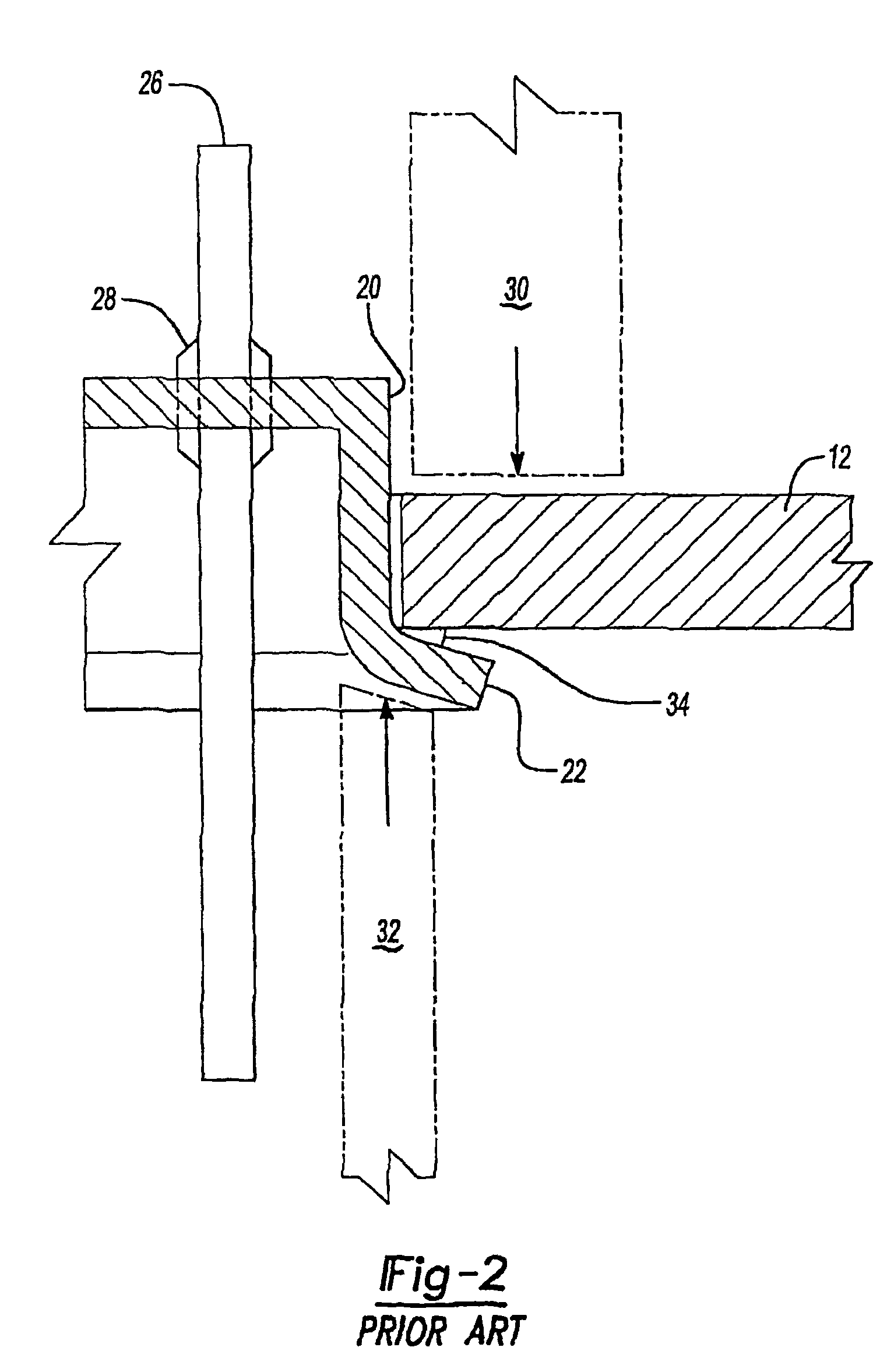

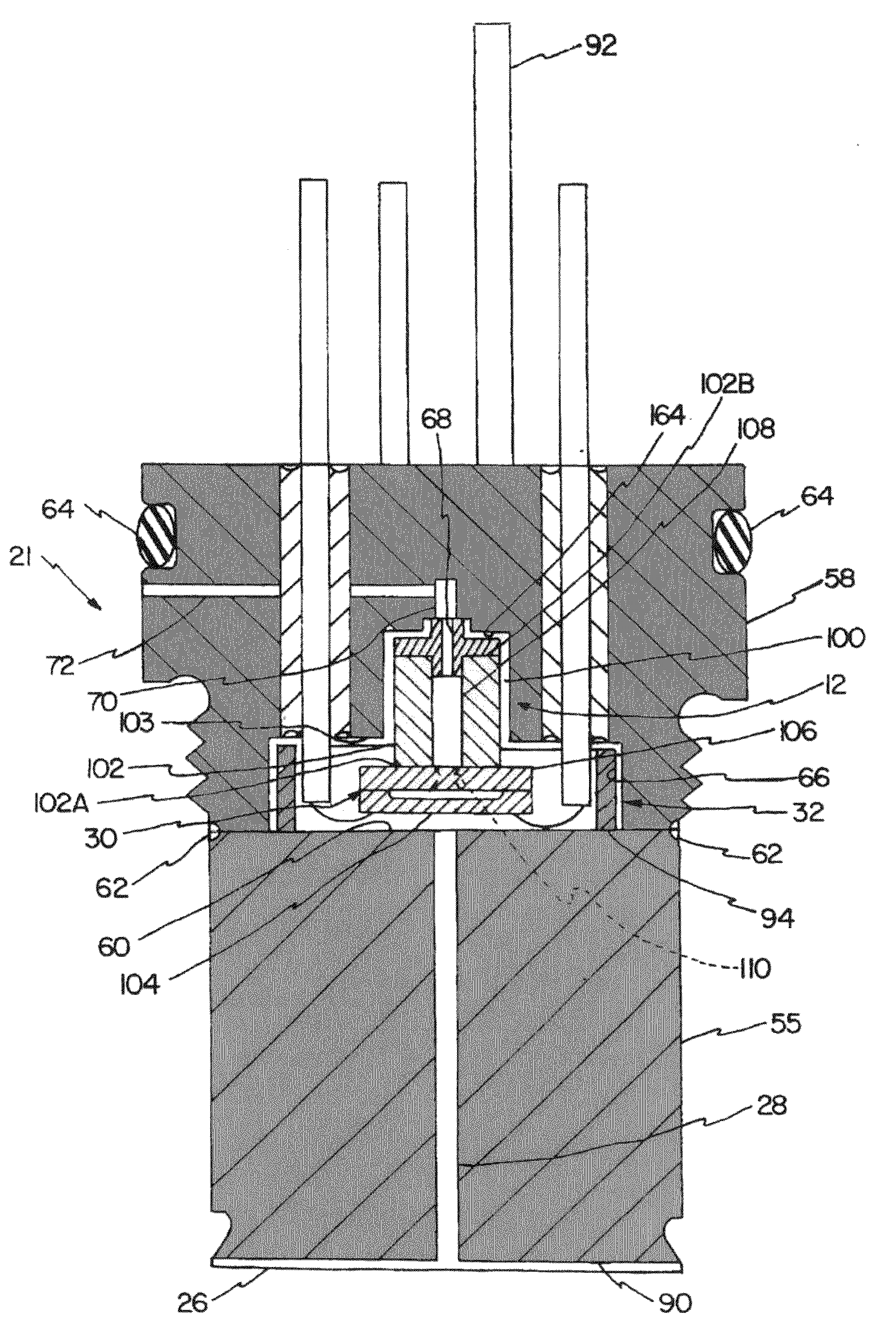

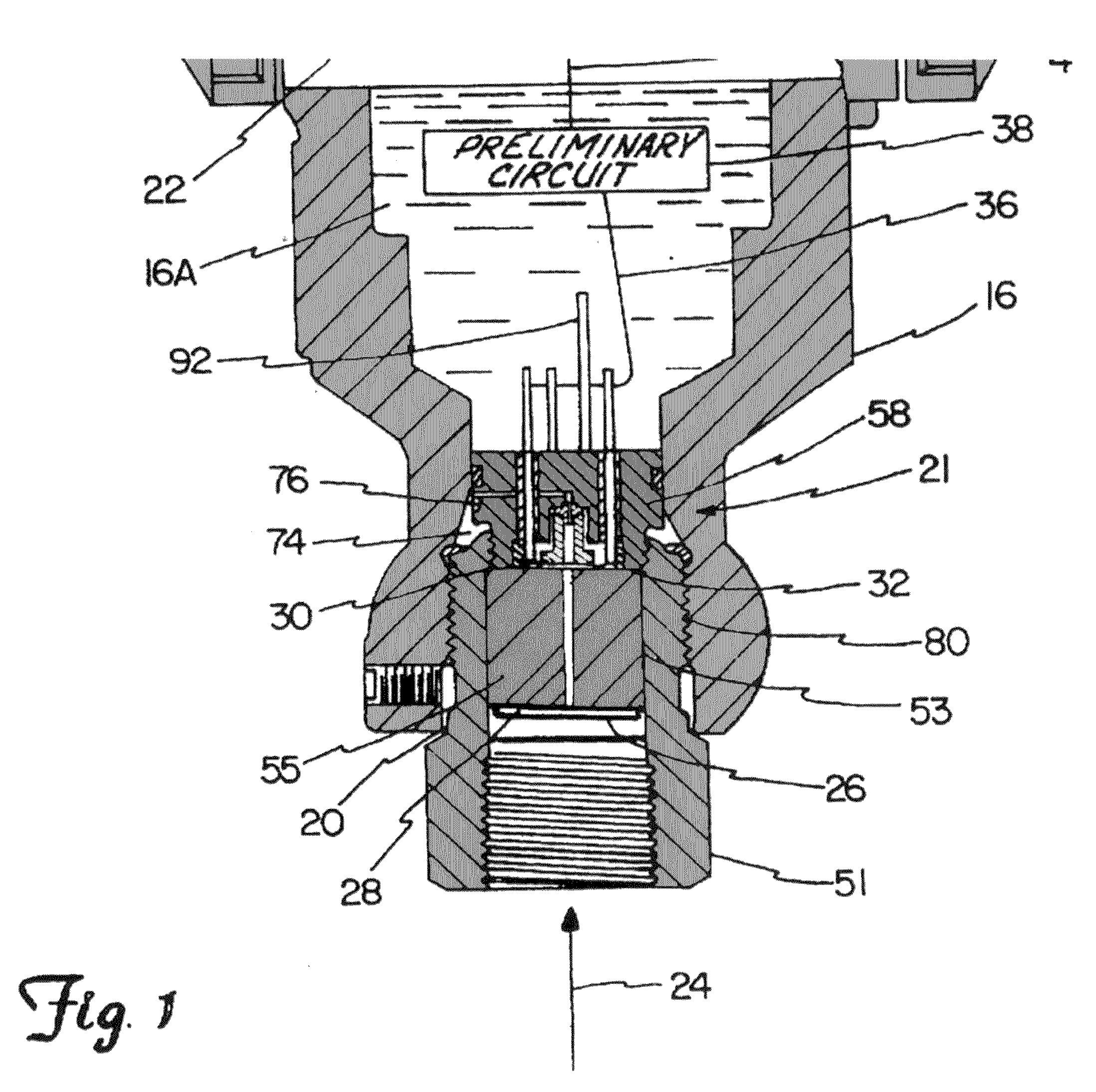

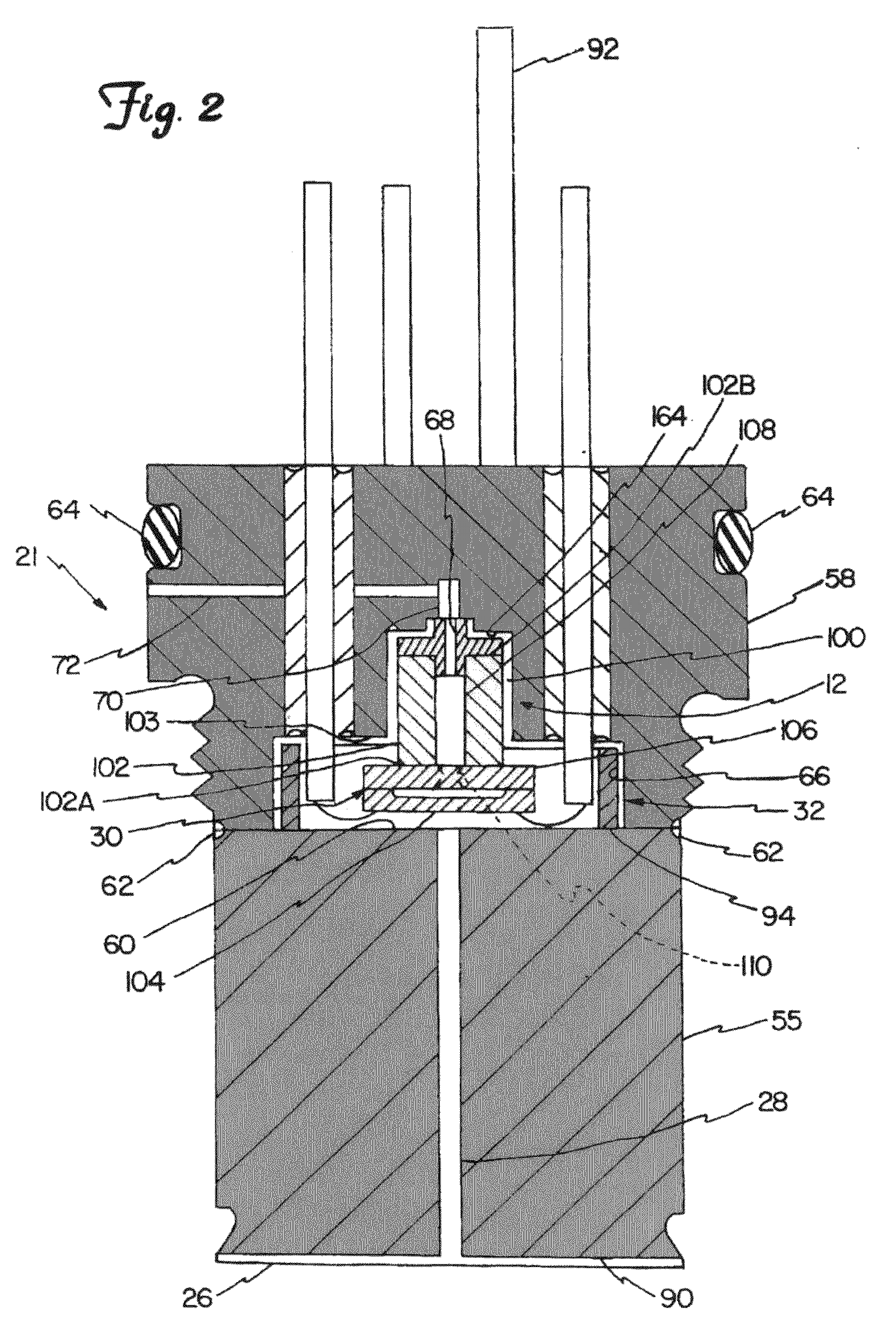

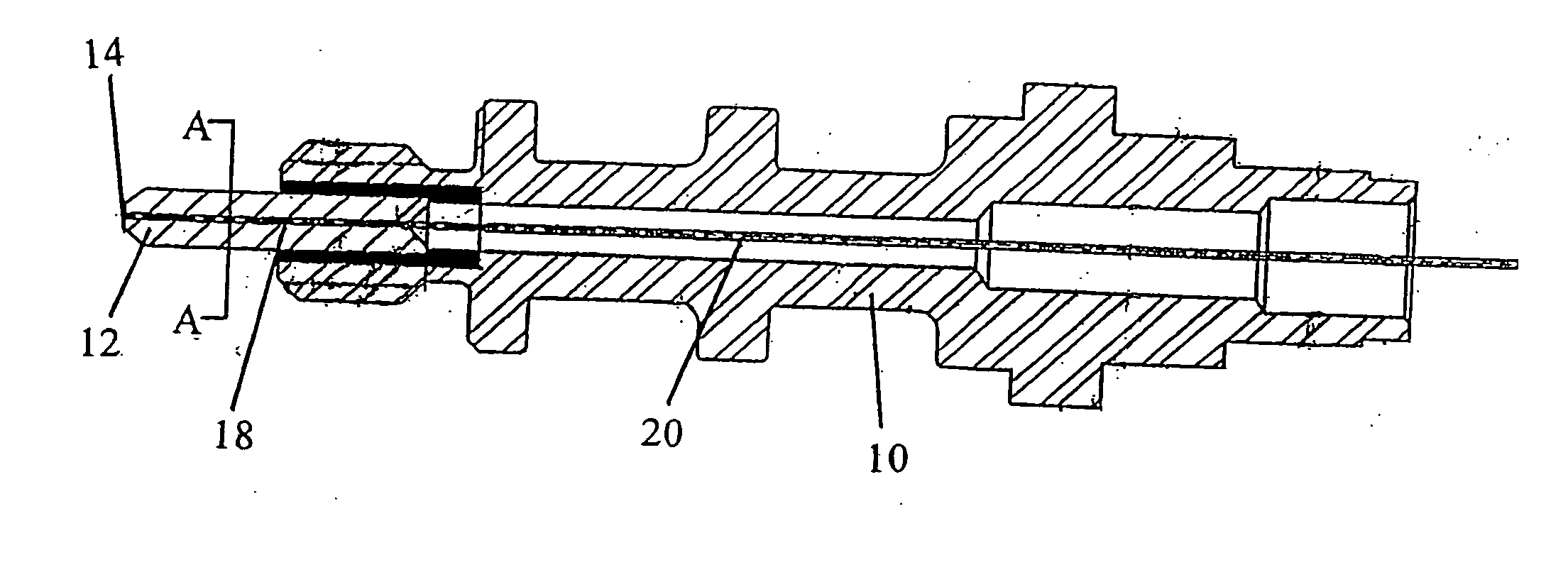

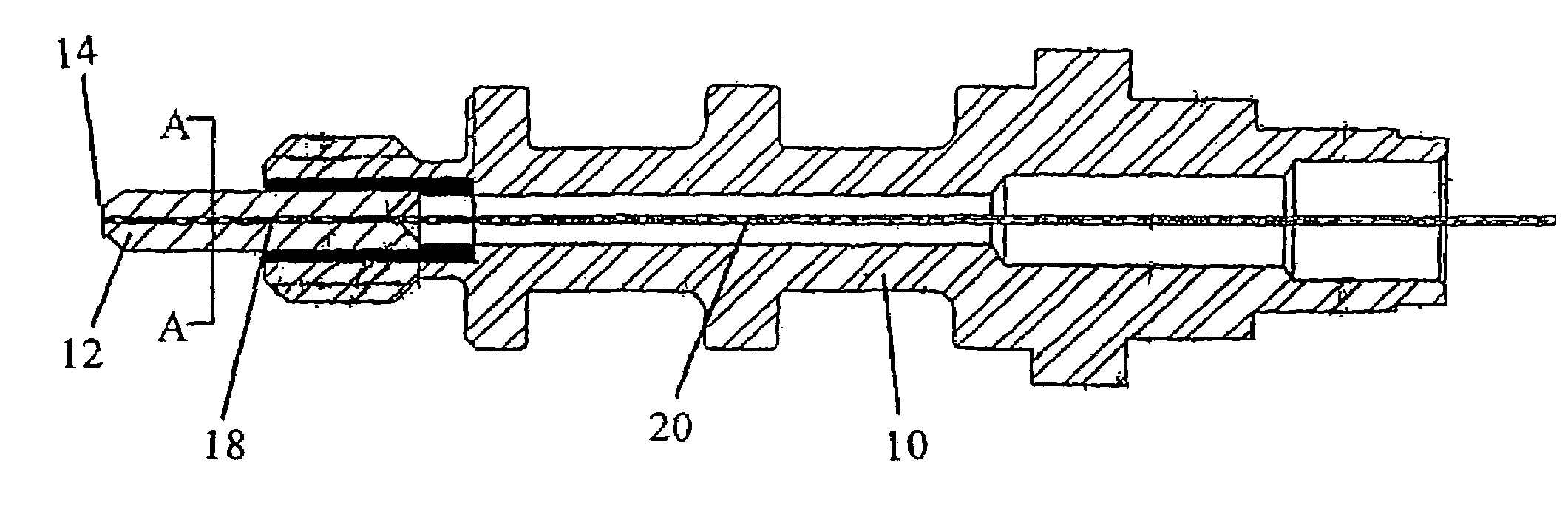

Hybrid glass-sealed electrical connectors

An electrical connector adapted for mounting to an electrical apparatus used in either high pressure or high temperature, or both high temperature and high pressure, applications. A metal body is provided for mounting to the electrical apparatus with at least one conductor for carrying electricity to or from the electrical apparatus extending therethrough and a thermoplastic jacket is applied over the conductors to the end of the metal body that is subjected to either high pressure or high temperature, or both high temperature and high pressure, for sealing around the conductor. An insulative material is interposed between the metal body and the conductor for sealing around the conductor. In addition to providing two independent internal and two independent external seals, the glass-to-metal seal limits cold-flow (creep) of thermoplastic along the pin and through the metal body. This feature effectively eliminates the catastrophic hydraulic failures possible with prior connectors utilizing a pin, metal body, and high temperature thermoplastic. Because of the redundant internal and external seals, the connector provides undistorted electrical performance in the most hostile environments of temperature and pressure.

Owner:RING JOHN H +1

Hybrid glass-sealed electrical connectors

An electrical connector adapted for mounting to an electrical apparatus used in either high pressure or high temperature, or both high temperature and high pressure, applications. A metal body is provided for mounting to the electrical apparatus with at least one conductor for carrying electricity to or from the electrical apparatus extending therethrough and a thermoplastic jacket is applied over the conductors to the end of the metal body that is subjected to either high pressure or high temperature, or both high temperature and high pressure, for sealing around the conductor. An insulative material is interposed between the metal body and the conductor for sealing around the conductor. In addition to providing two independent internal and two independent external seals, the glass-to-metal seal limits cold-flow (creep) of thermoplastic along the pin and through the metal body. This feature effectively eliminates the catastrophic hydraulic failures possible with prior connectors utilizing a pin, metal body, and high temperature thermoplastic. Because of the redundant internal and external seals, the connector provides undistorted electrical performance in the most hostile environments of temperature and pressure.

Owner:RING JOHN H +1

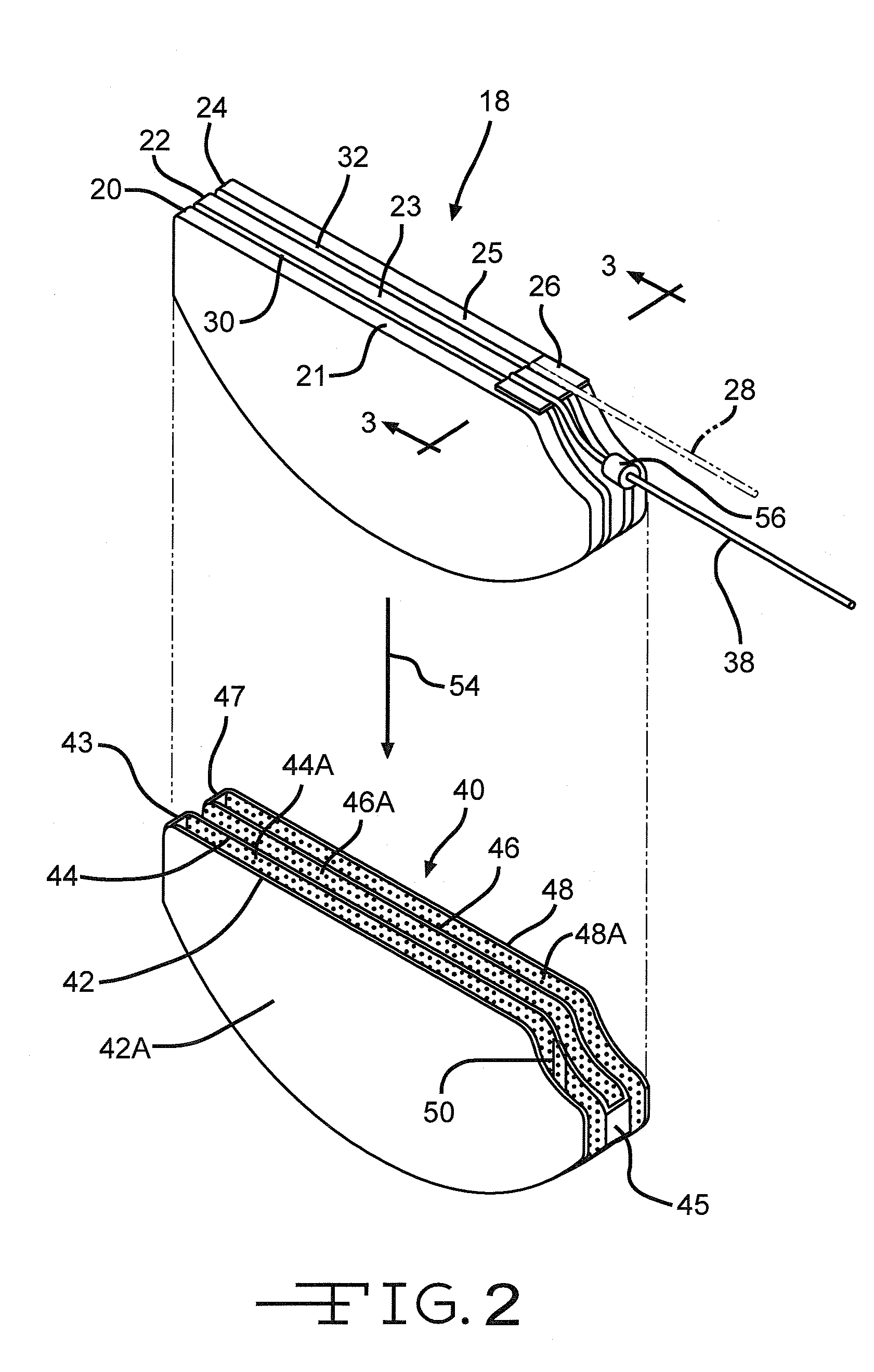

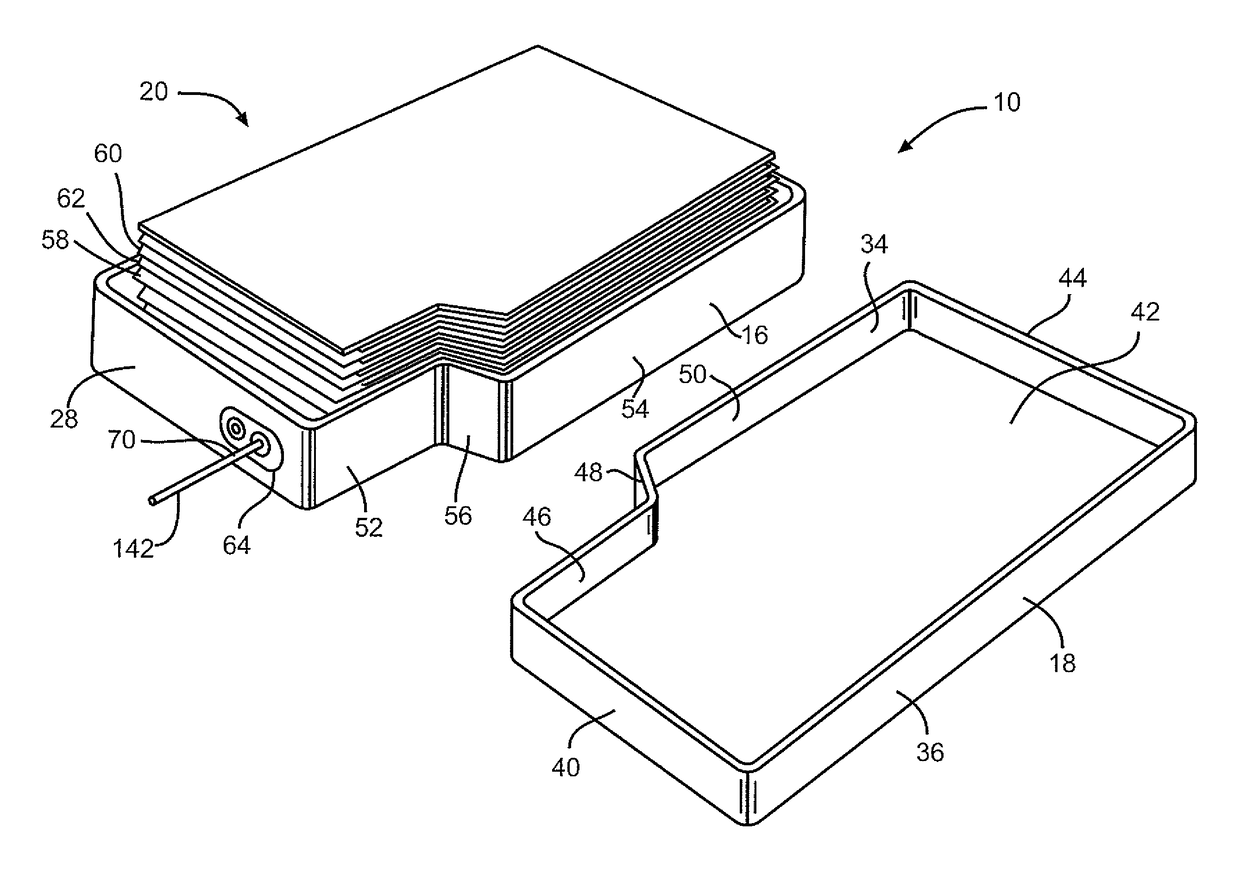

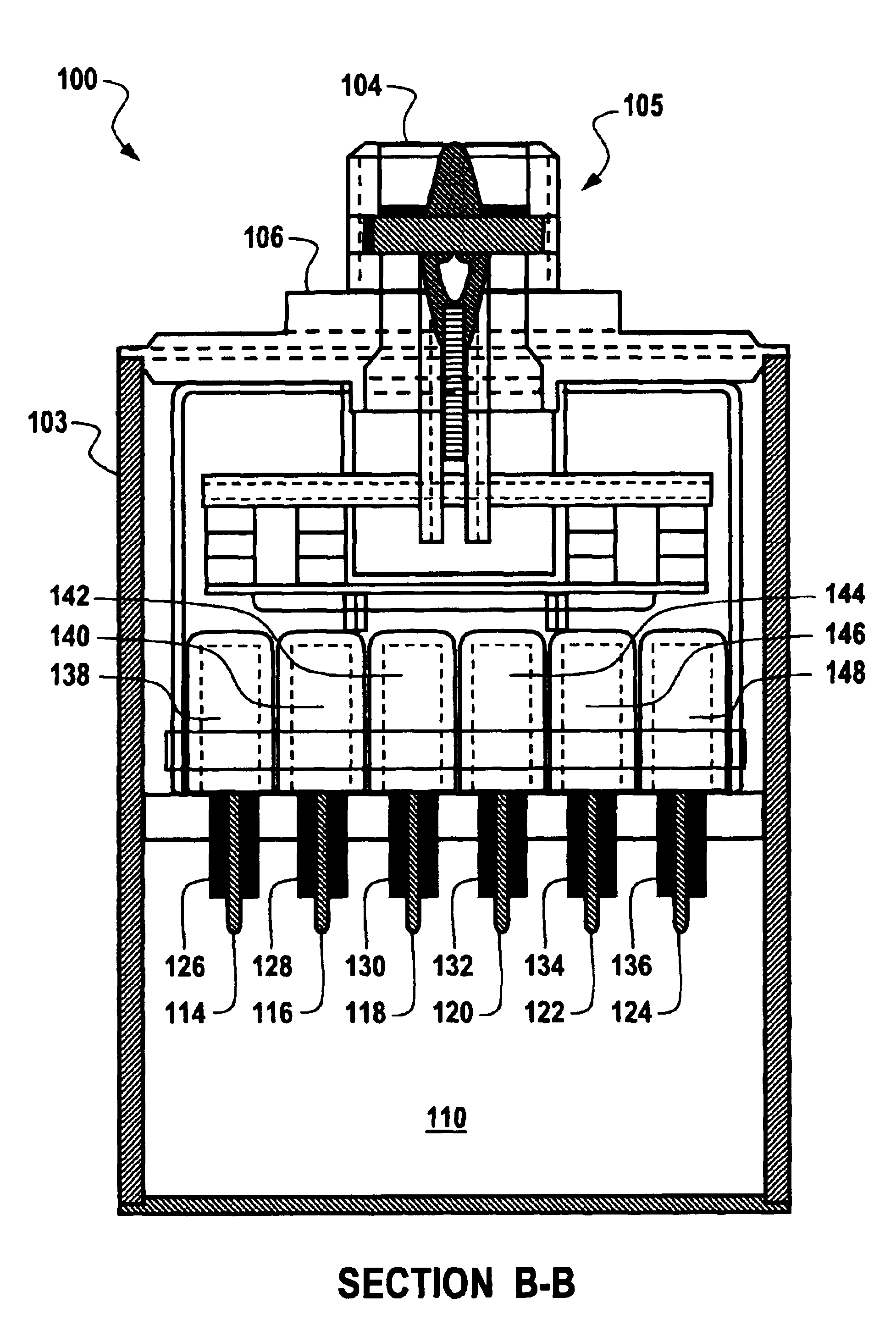

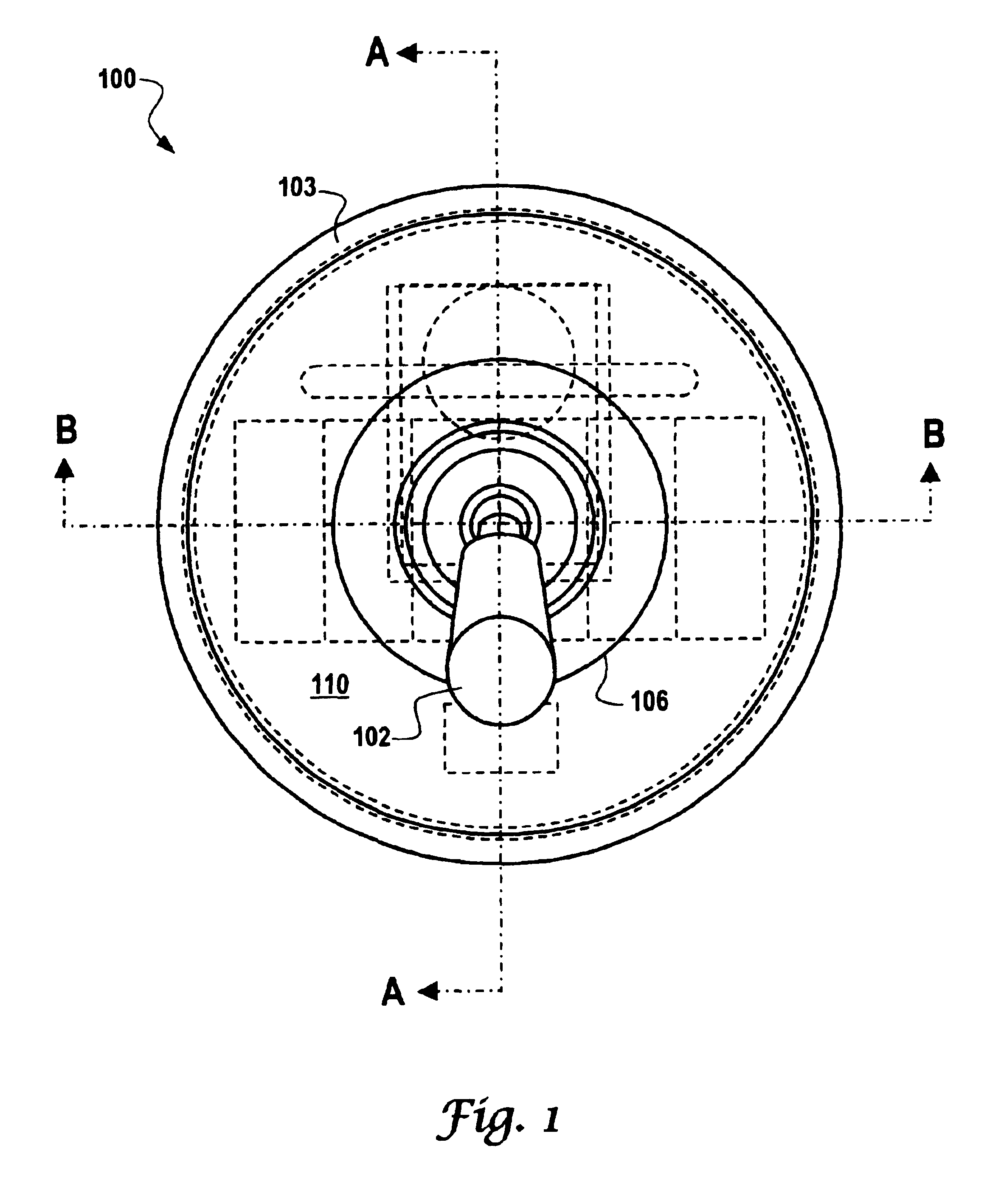

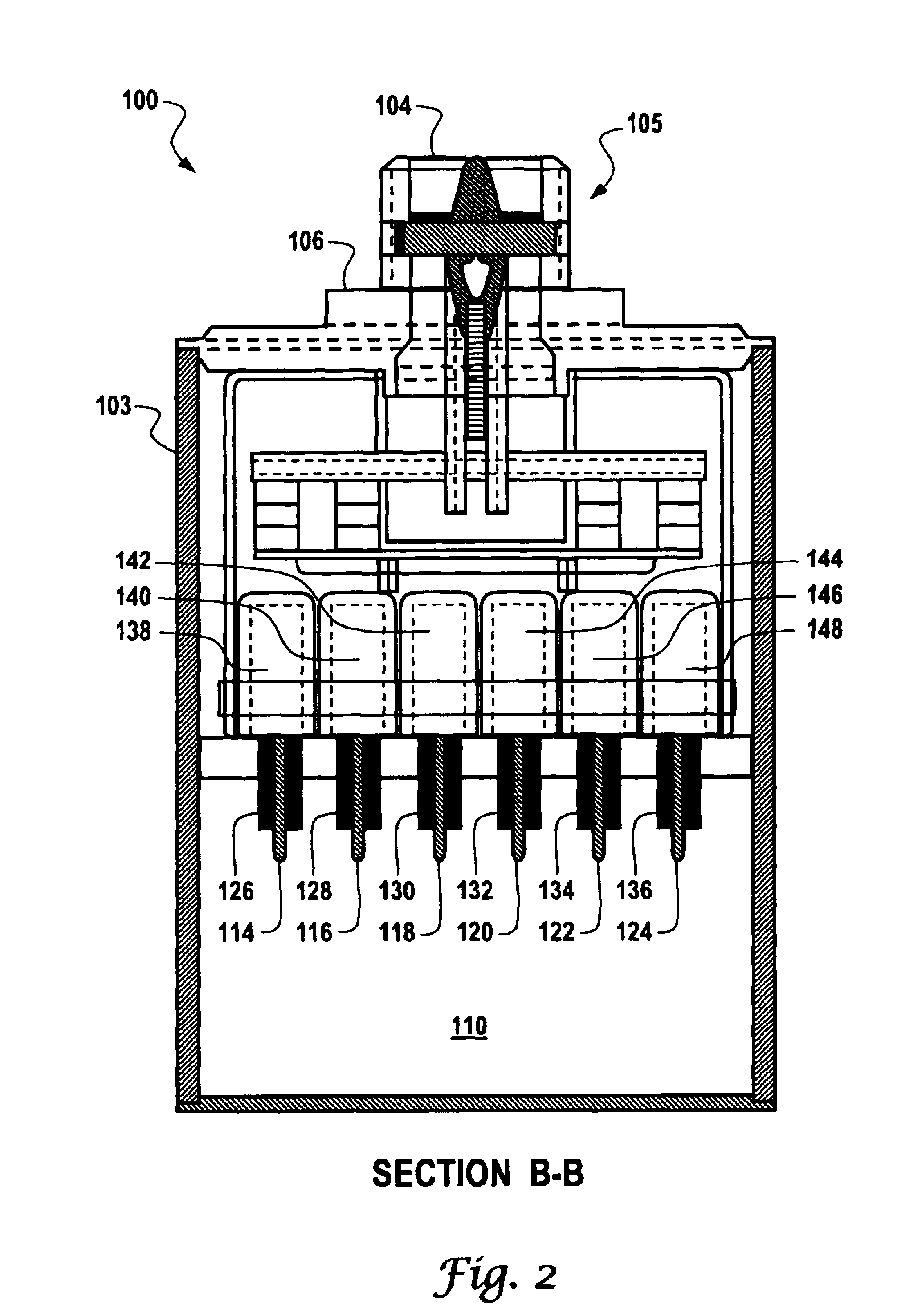

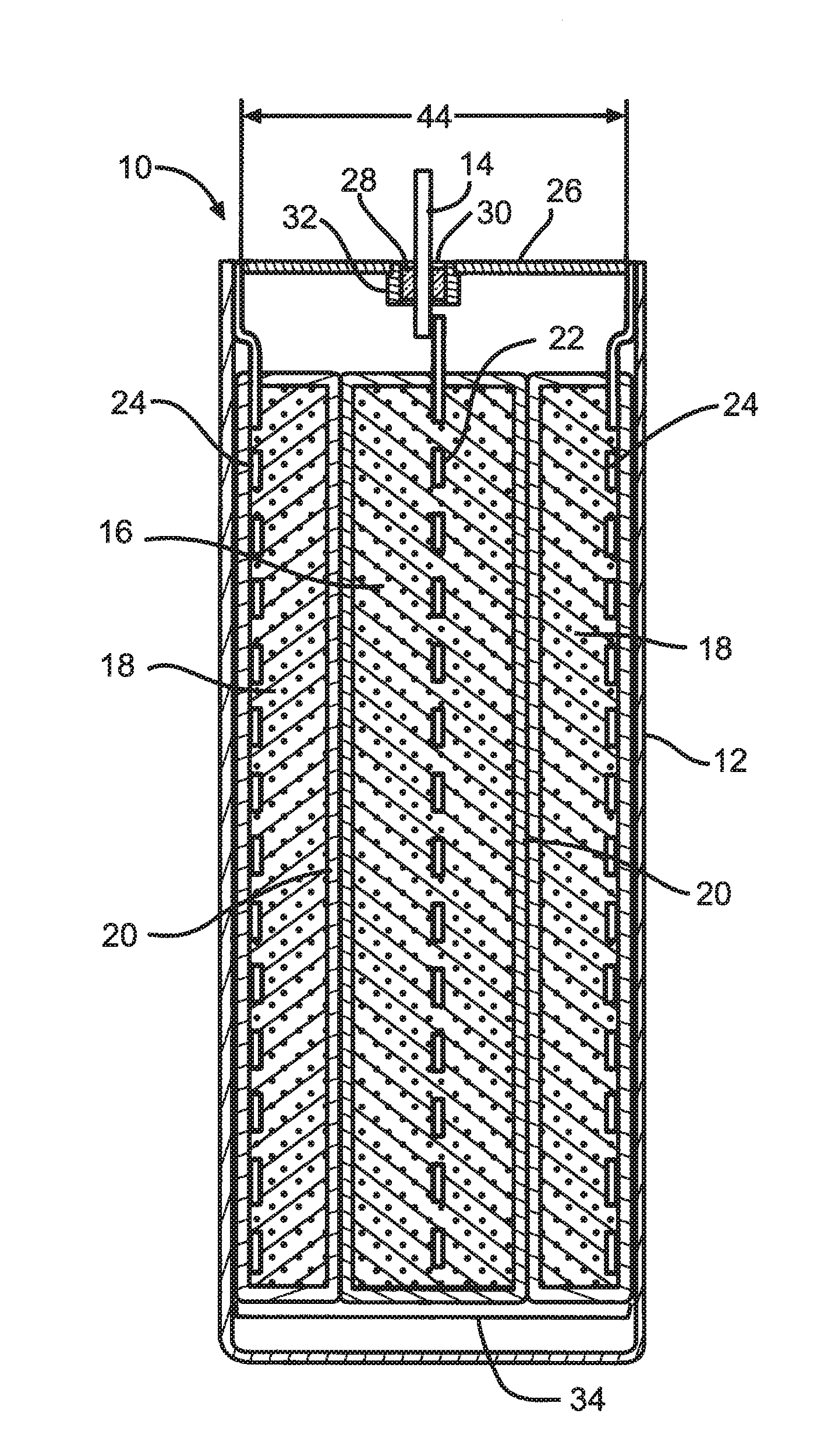

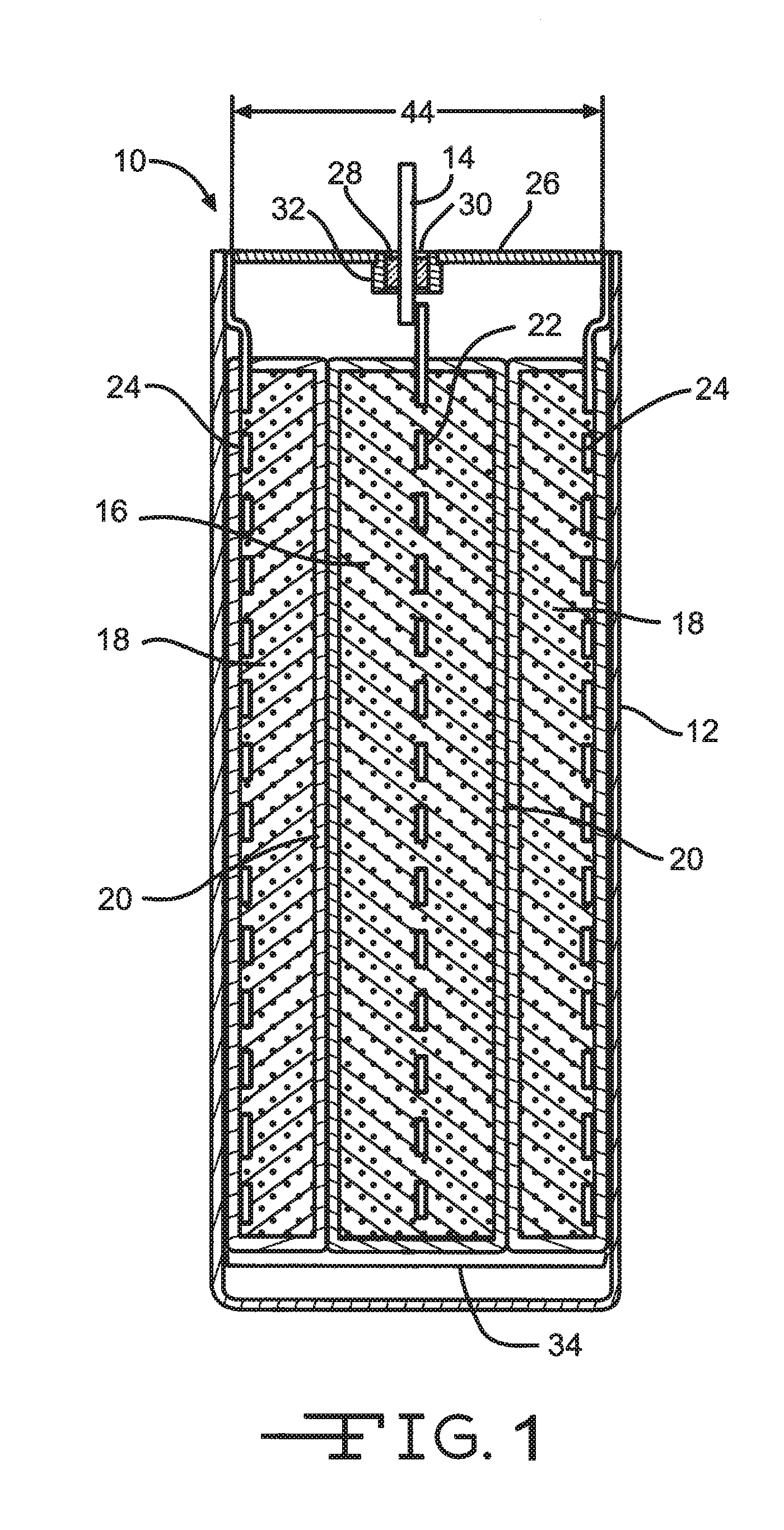

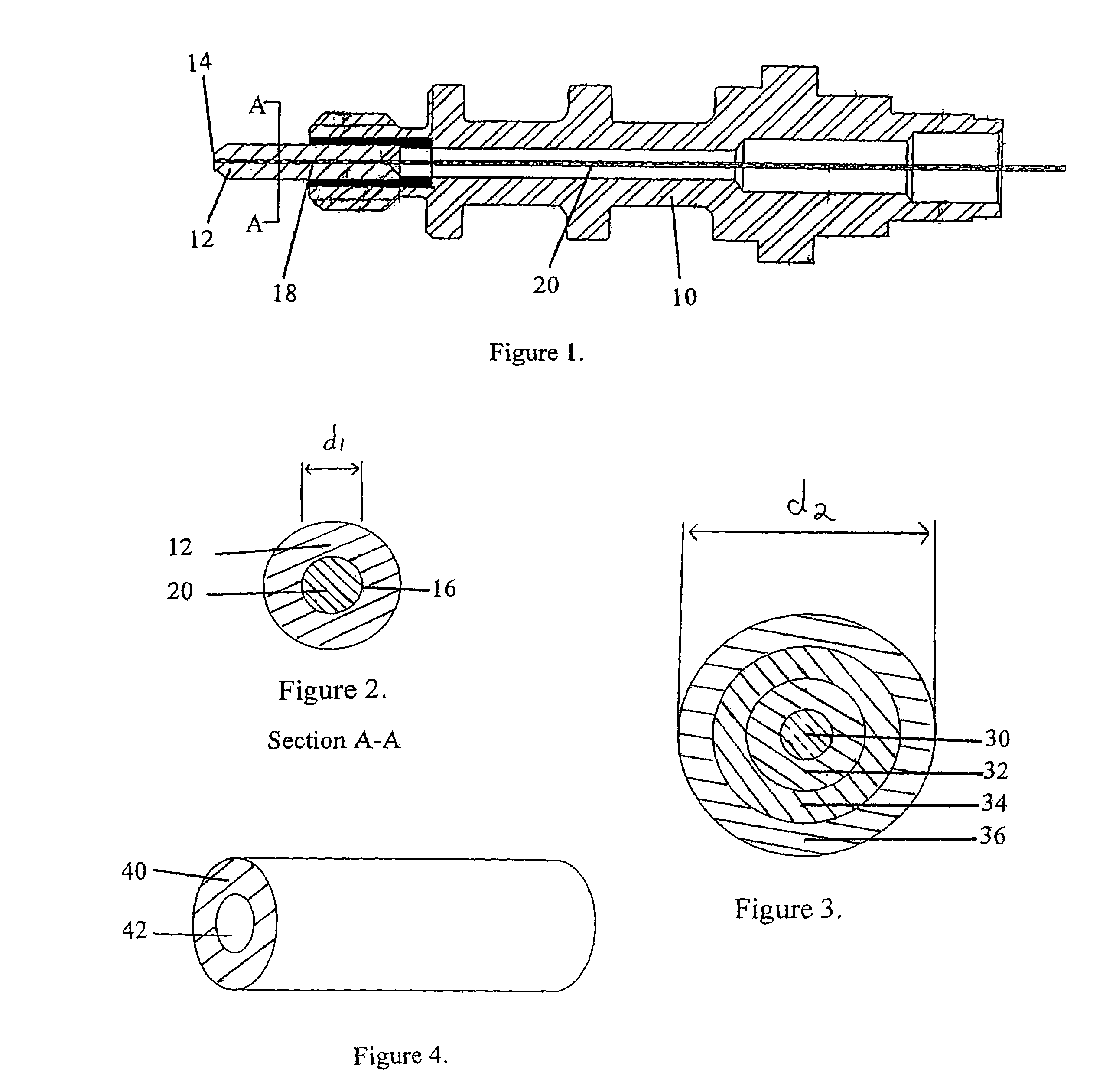

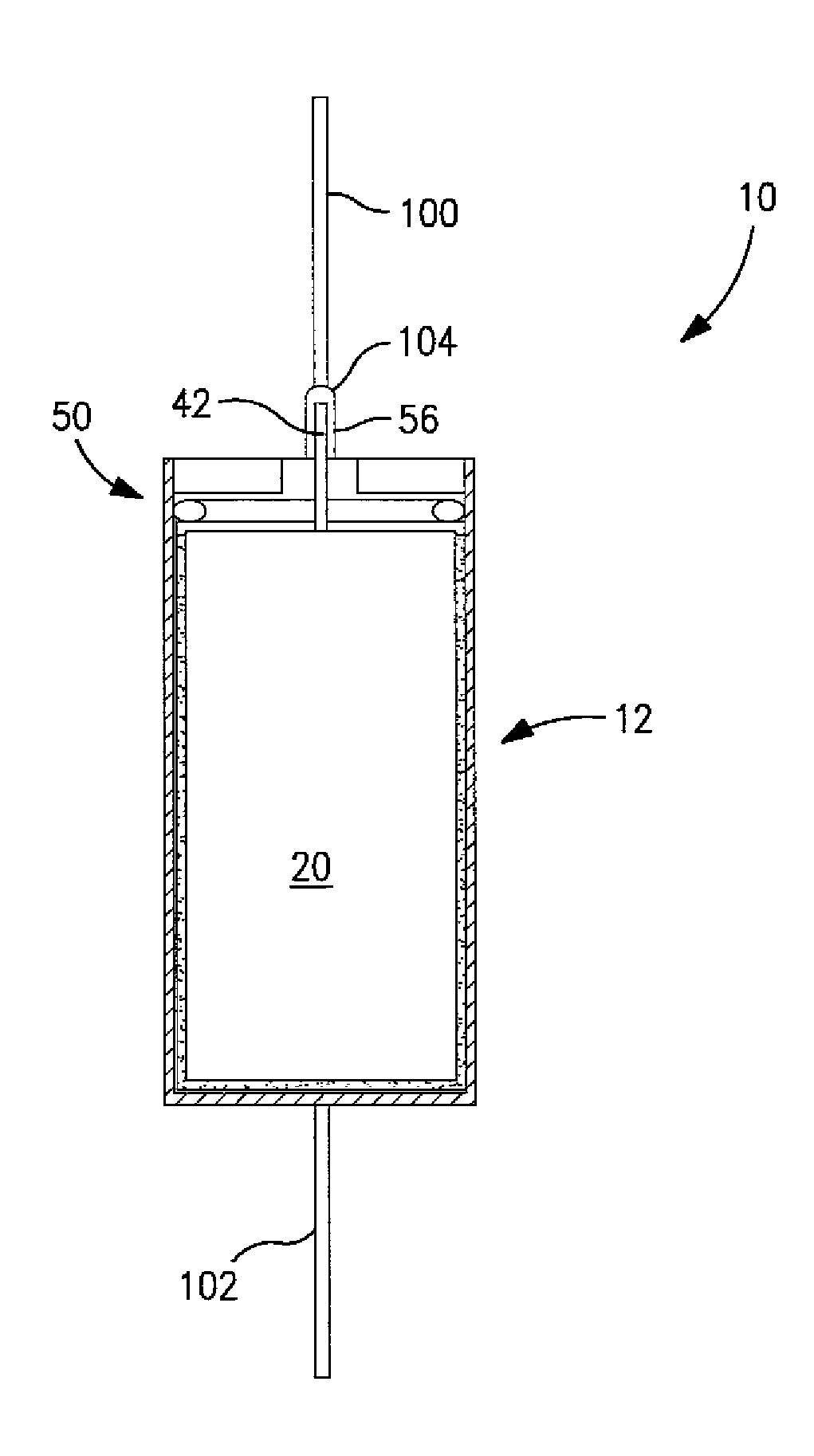

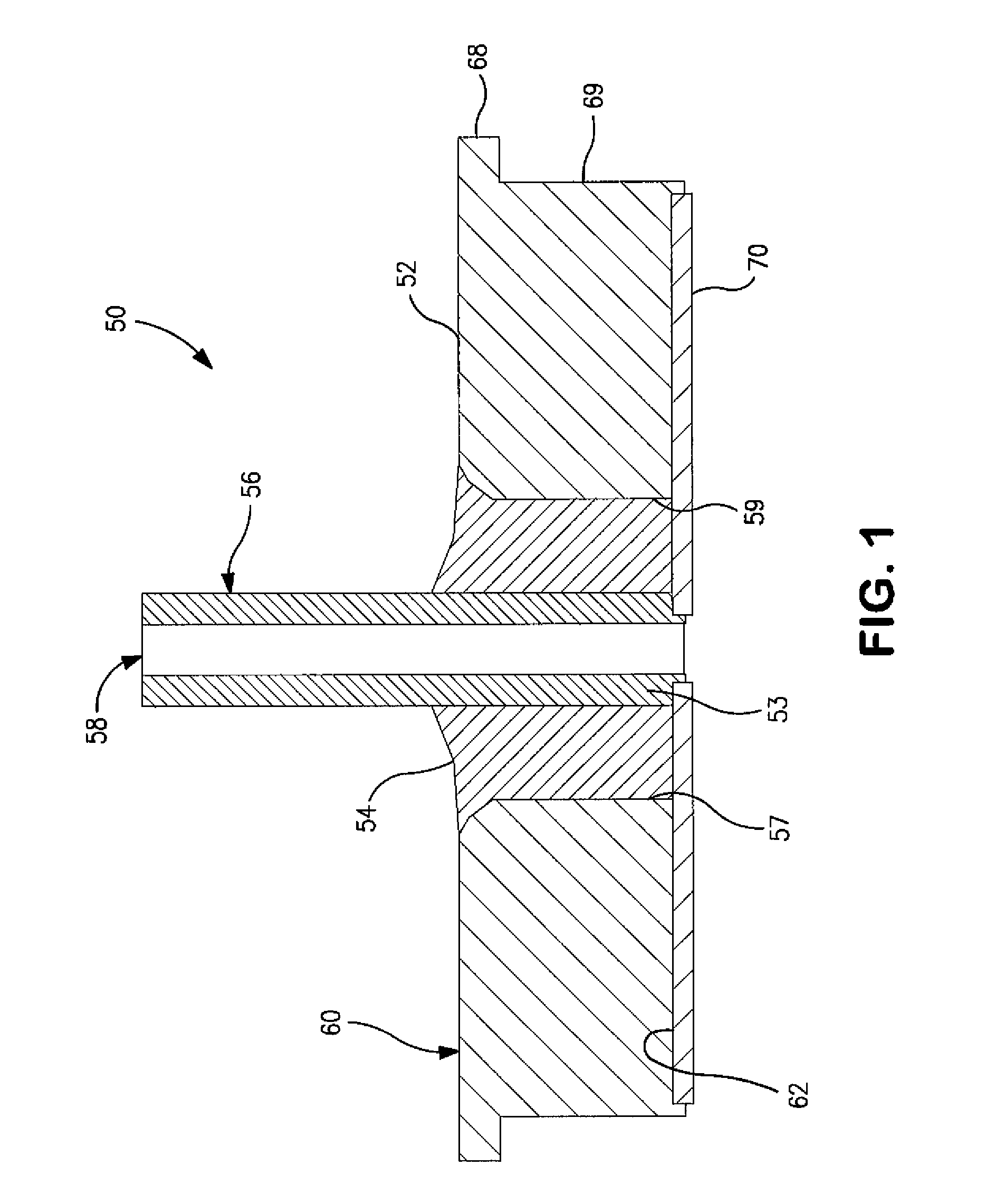

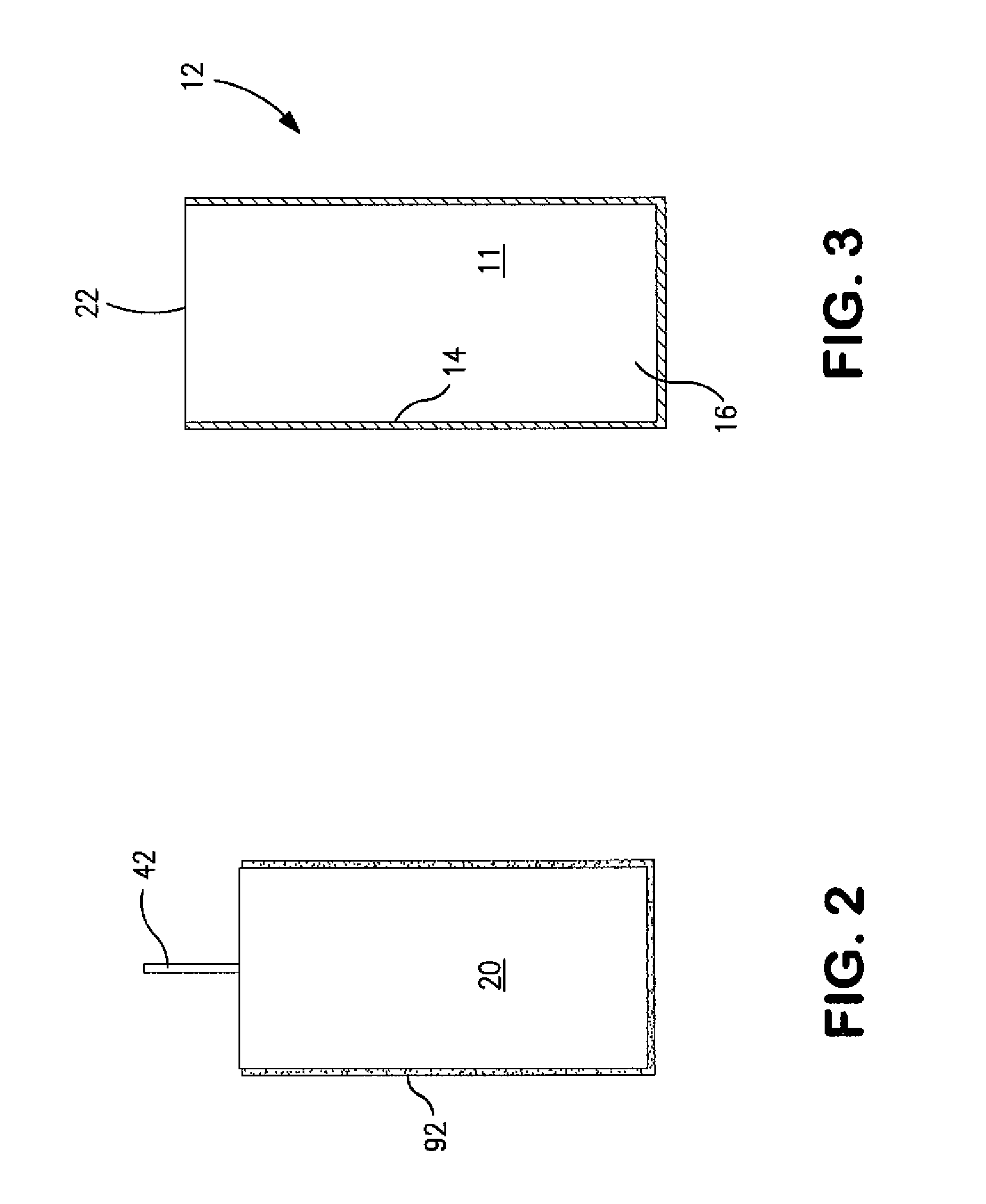

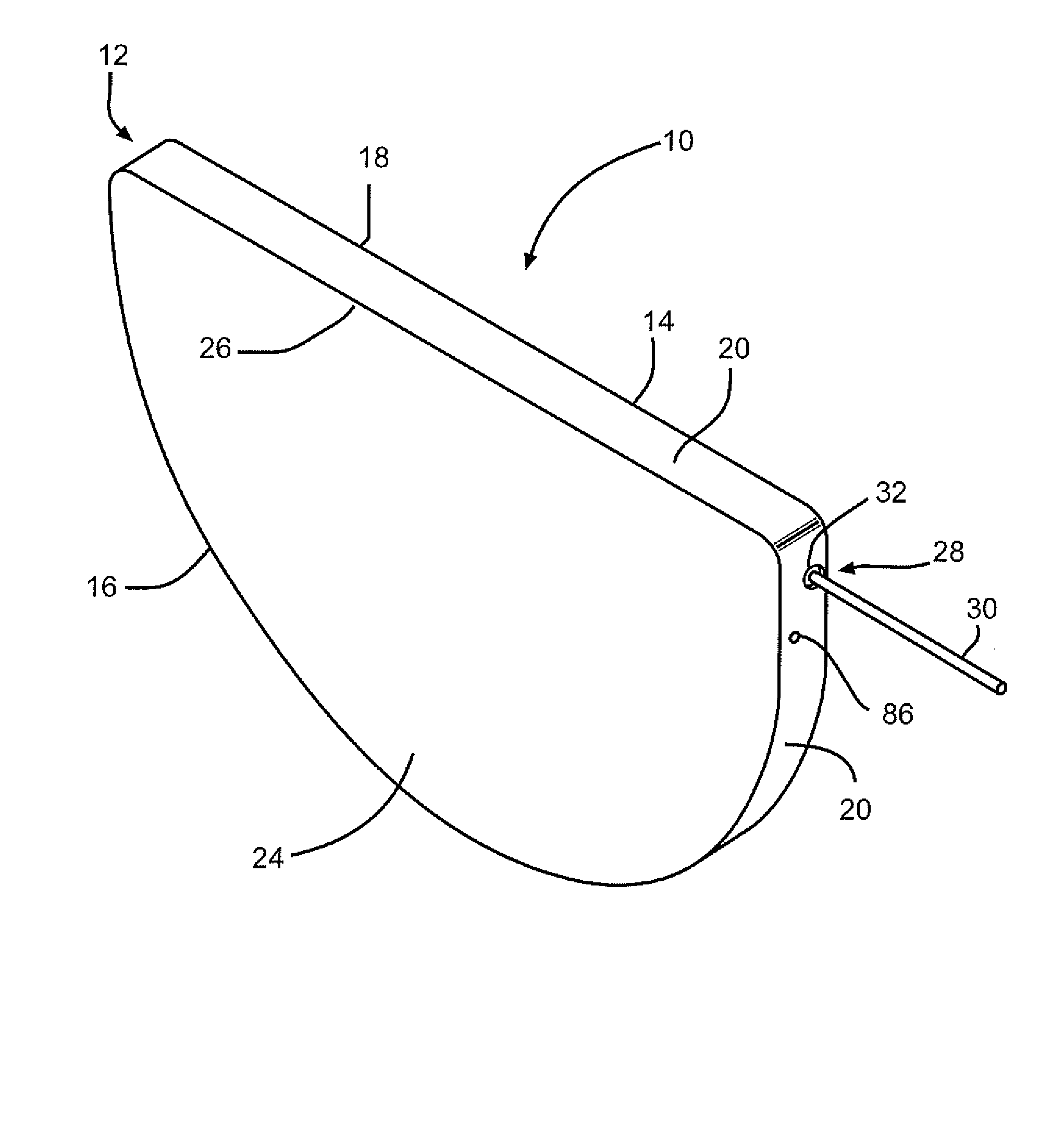

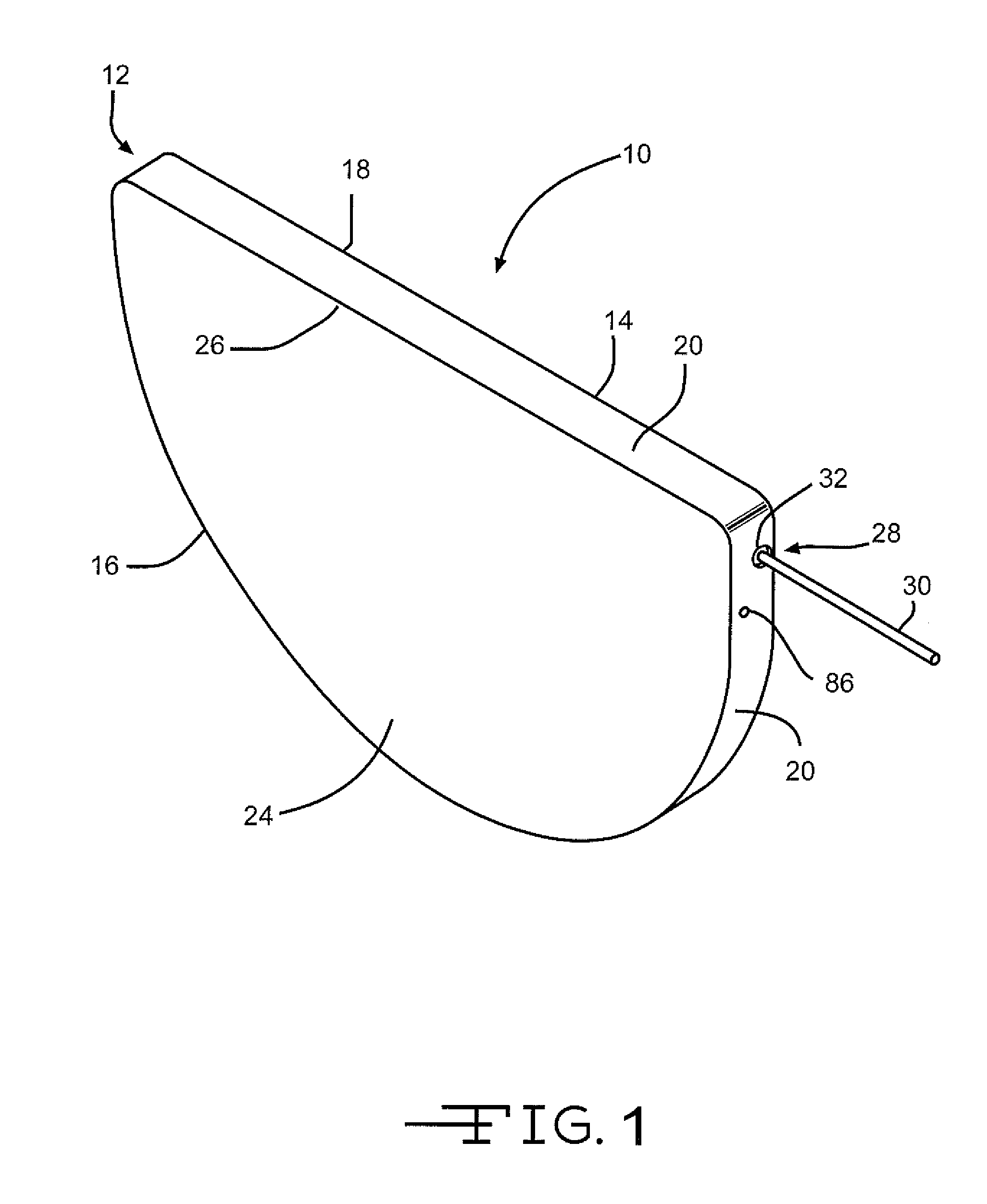

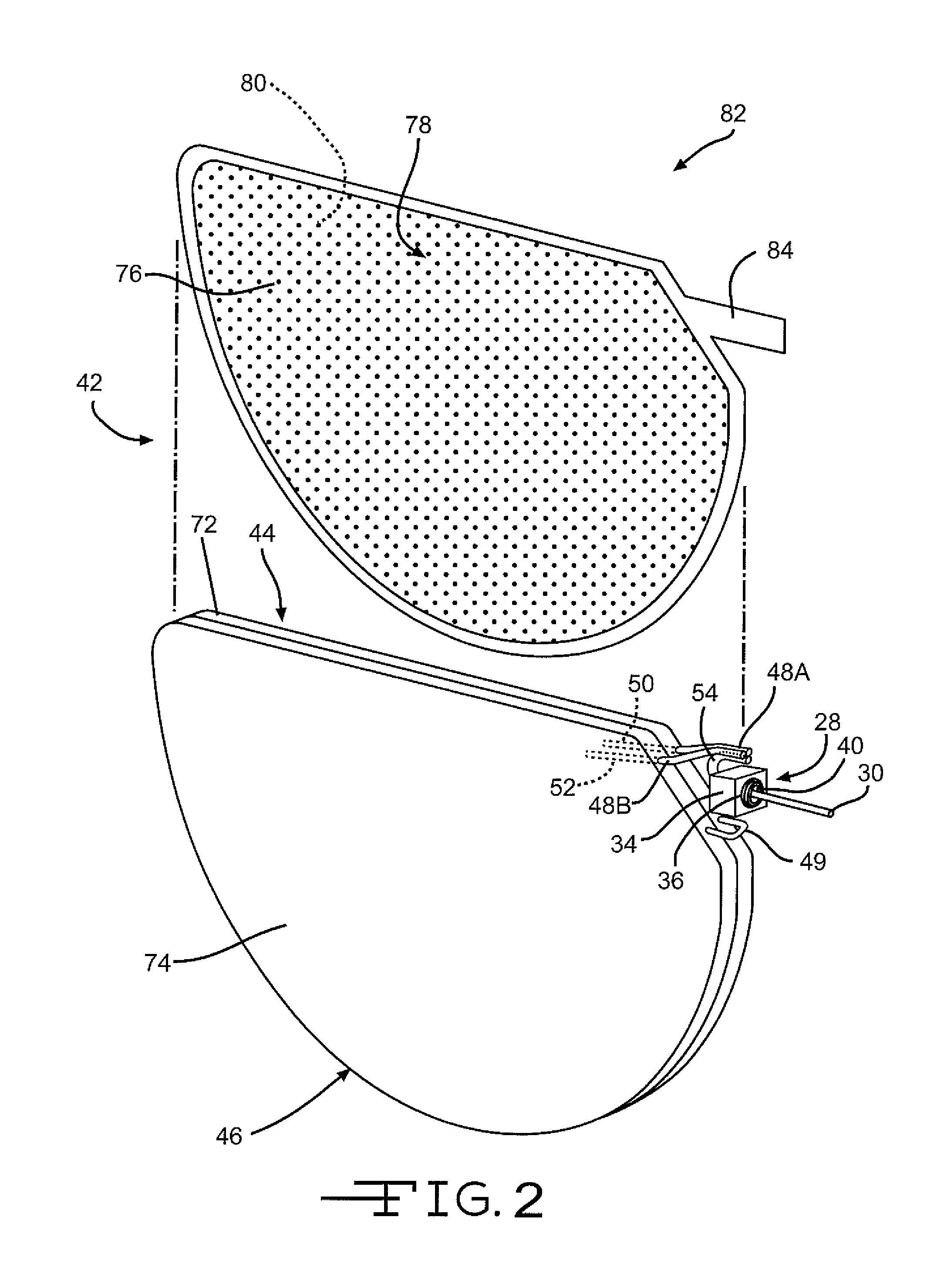

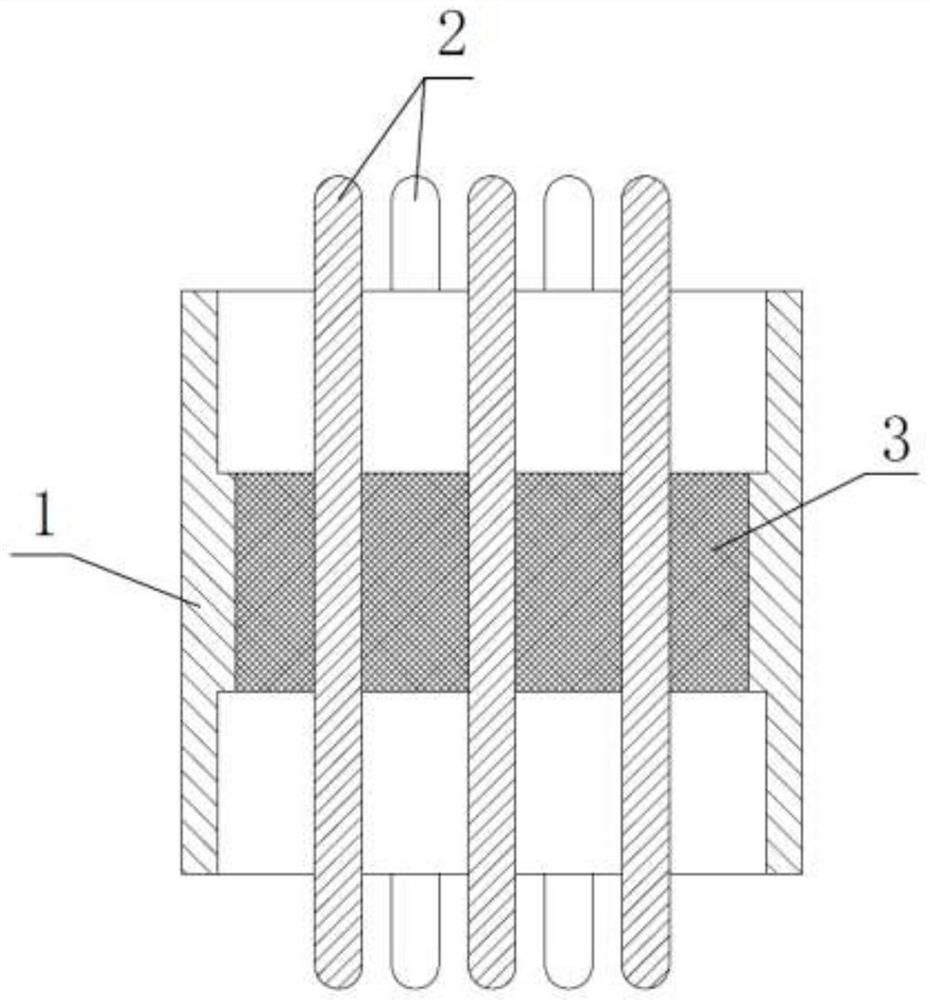

Wet tantalum capacitor with multiple anode connections

A capacitor assembly comprising a casing, an anode pack housed within the casing and comprising two or more anode pellets of anode active material electrically connected to each other by a bridge, and a cathode comprised of cathode current collectors including major faces with cathode active material provided thereupon is described. The bridge, which spans between sidewalls of the anode pellets, helps maintain them in a parallel alignment. The bridge is also a convenient location to connect the feedthrough wire that exits the casing through a glass-to-metal seal. The cathode current collectors are disposed between adjacent anode pellets and are electrically connected to each other and to the casing. A feedthrough wire electrically connected to the anode pack extends outside the casing in electrical isolation there from. An electrolyte is provided to activate the anode and the cathode.

Owner:WILSON GREATBATCH LTD

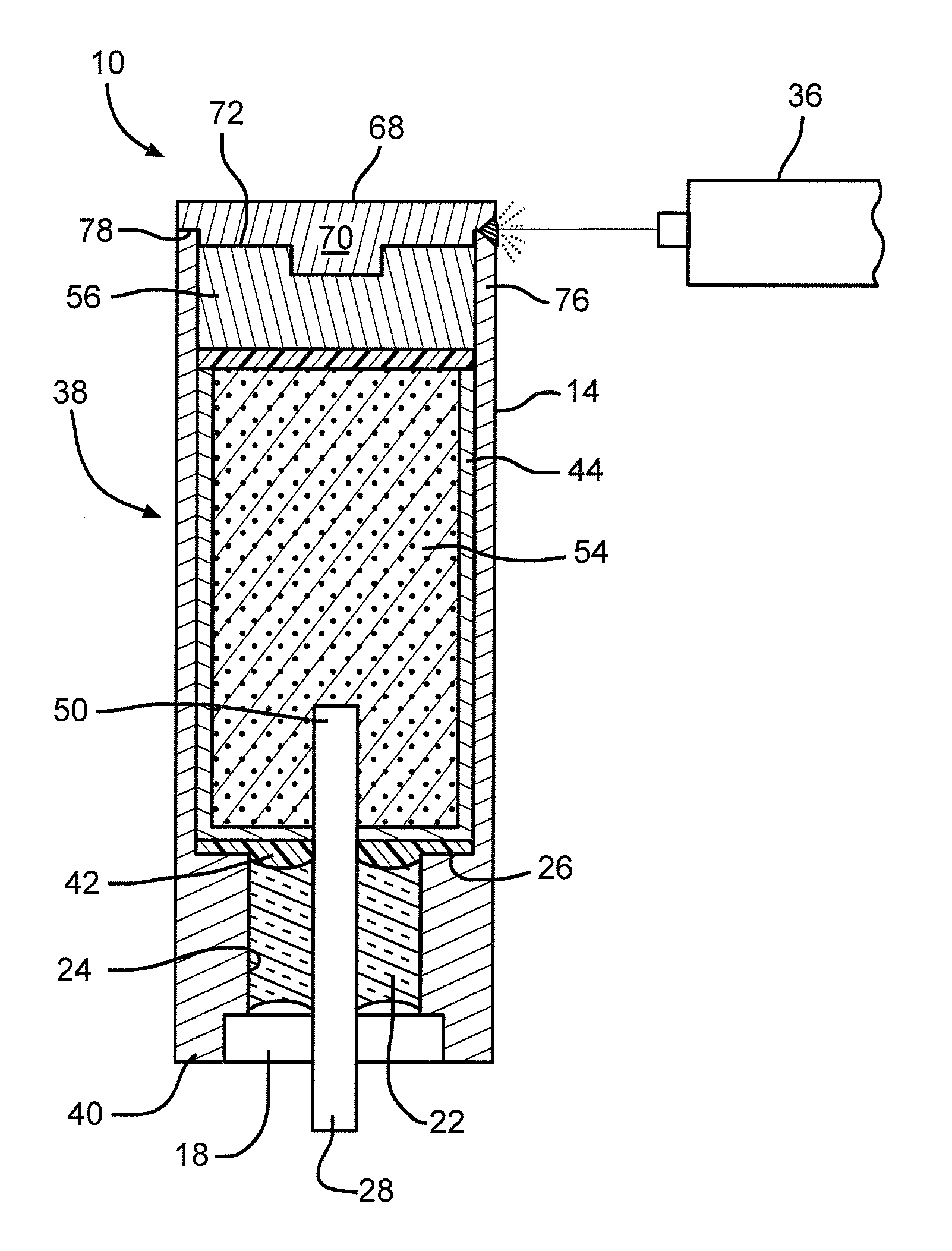

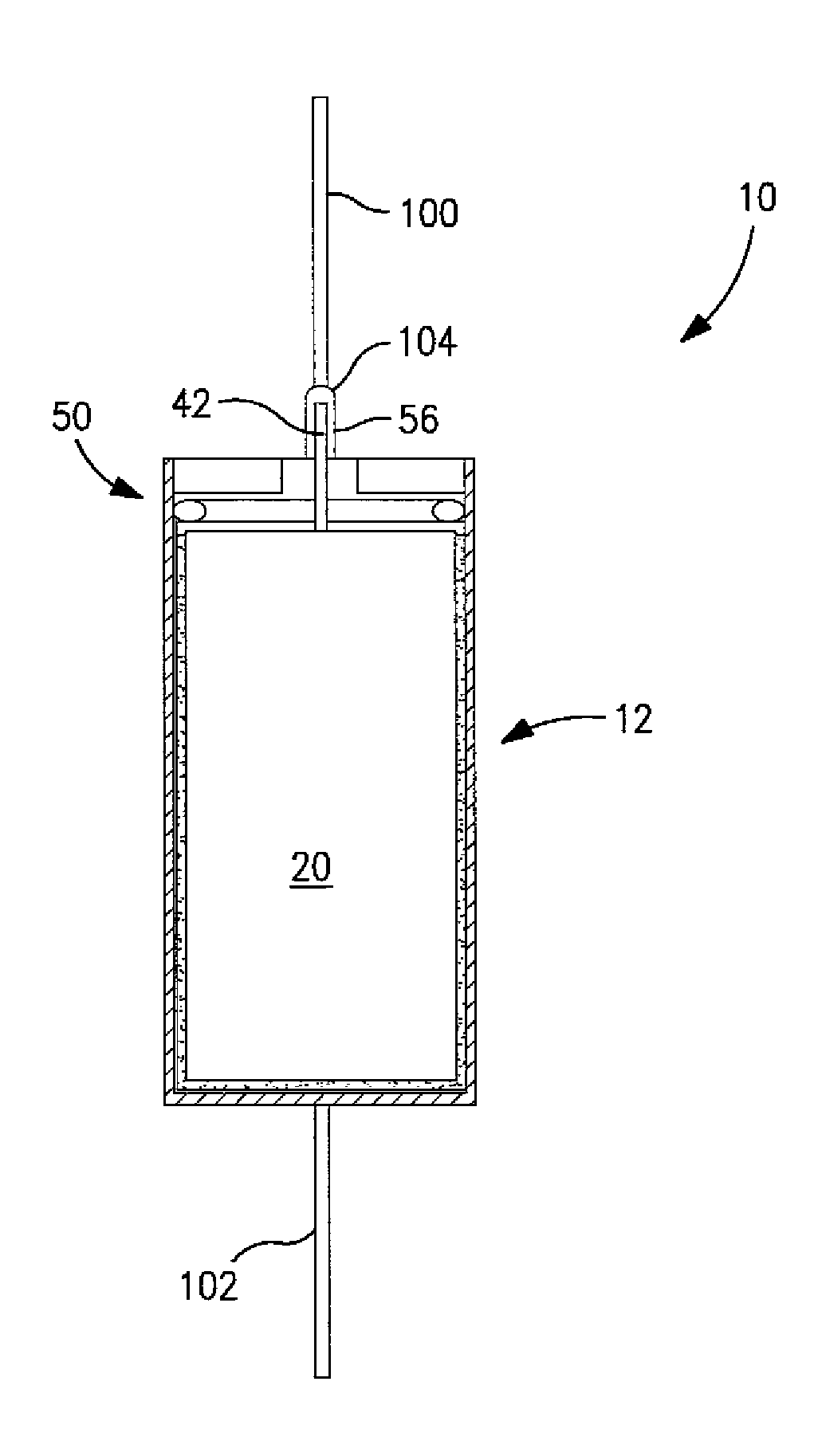

Highly Compact Electrochemical Cell

InactiveUS20080085451A1Cell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsEngineeringElectrochemical cell

A highly compact electrochemical cell comprised of a casing having a proximal opening, a distal opening, and an intermediate sidewall surrounding an enclosed volume. A glass-to-metal seal is disposed in the proximal opening and within the enclosed volume of the casing, and a terminal pin extends from outside the casing through the glass-to-metal seal into the enclosed casing volume. An insulator is disposed along the casing sidewall. A cathode is contained within the insulator in electrical contact with the terminal pin. A separator disc is disposed contiguously with the casing sidewall and in contact with the cathode. An anode is provided in contact with the separator disc and with the casing sidewall opposite the cathode. An electrolyte is provided within the cell, and a lid is sealed to the casing to hermetically enclose the cell contents.

Owner:WILSON GREATBATCH LTD

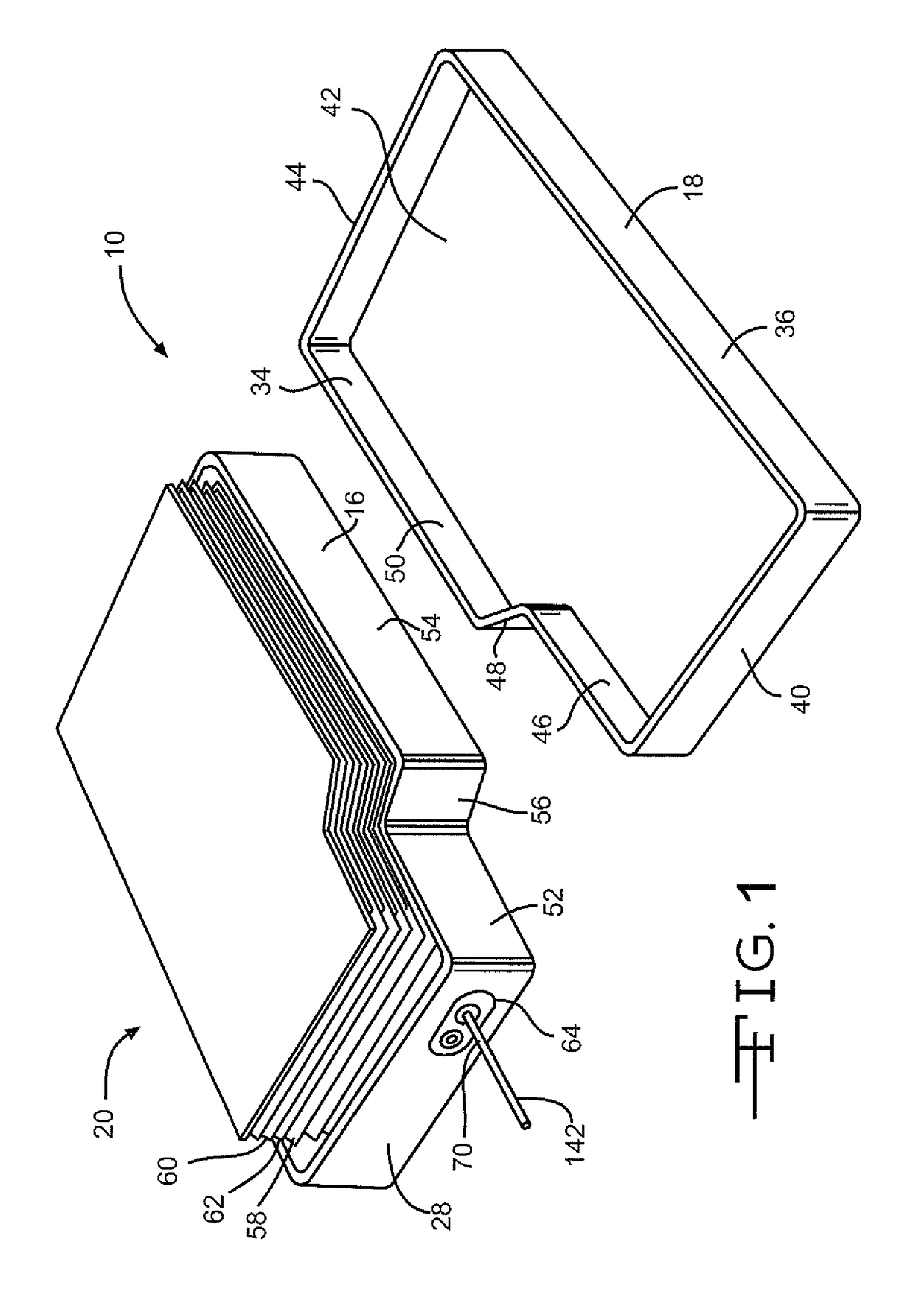

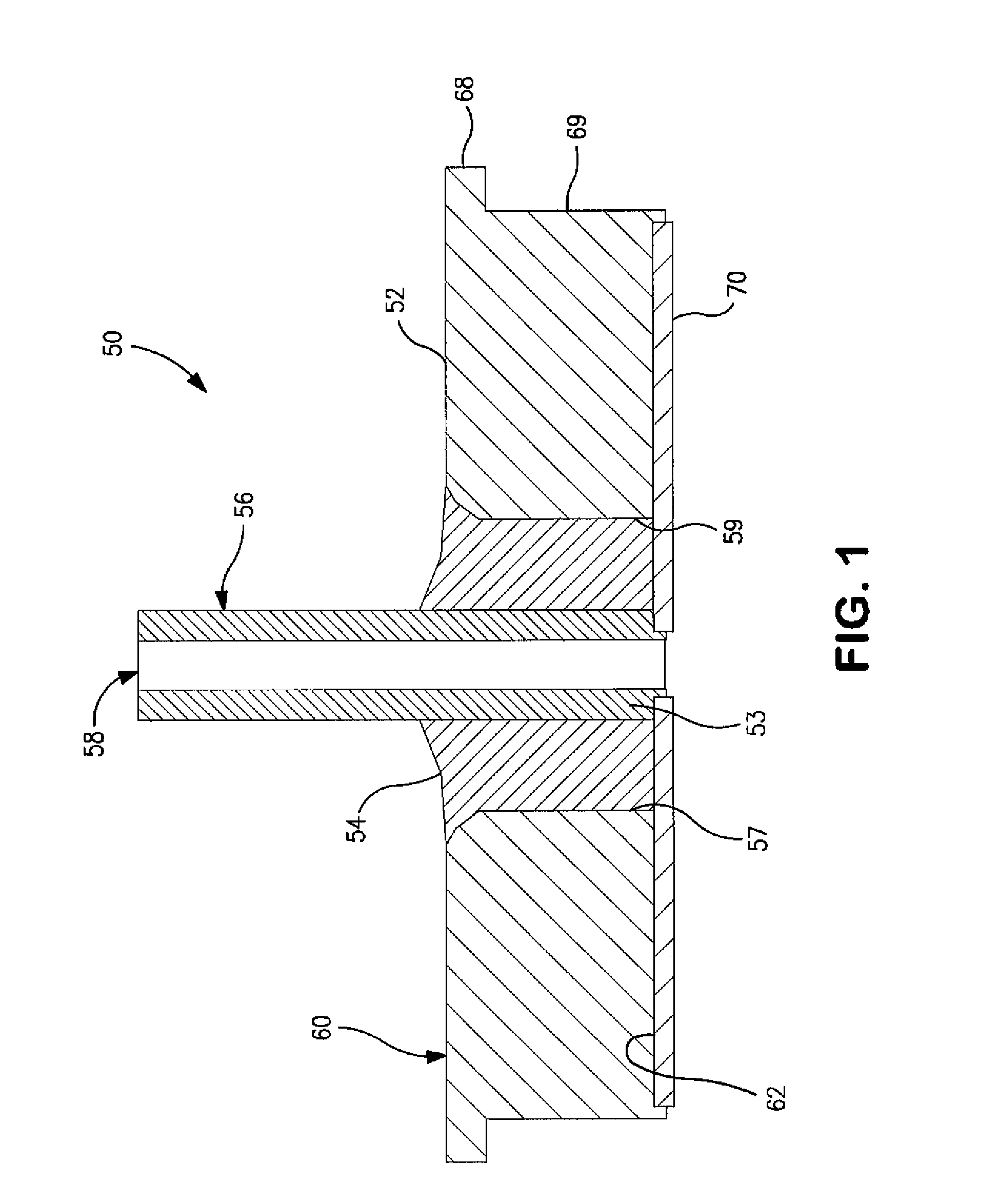

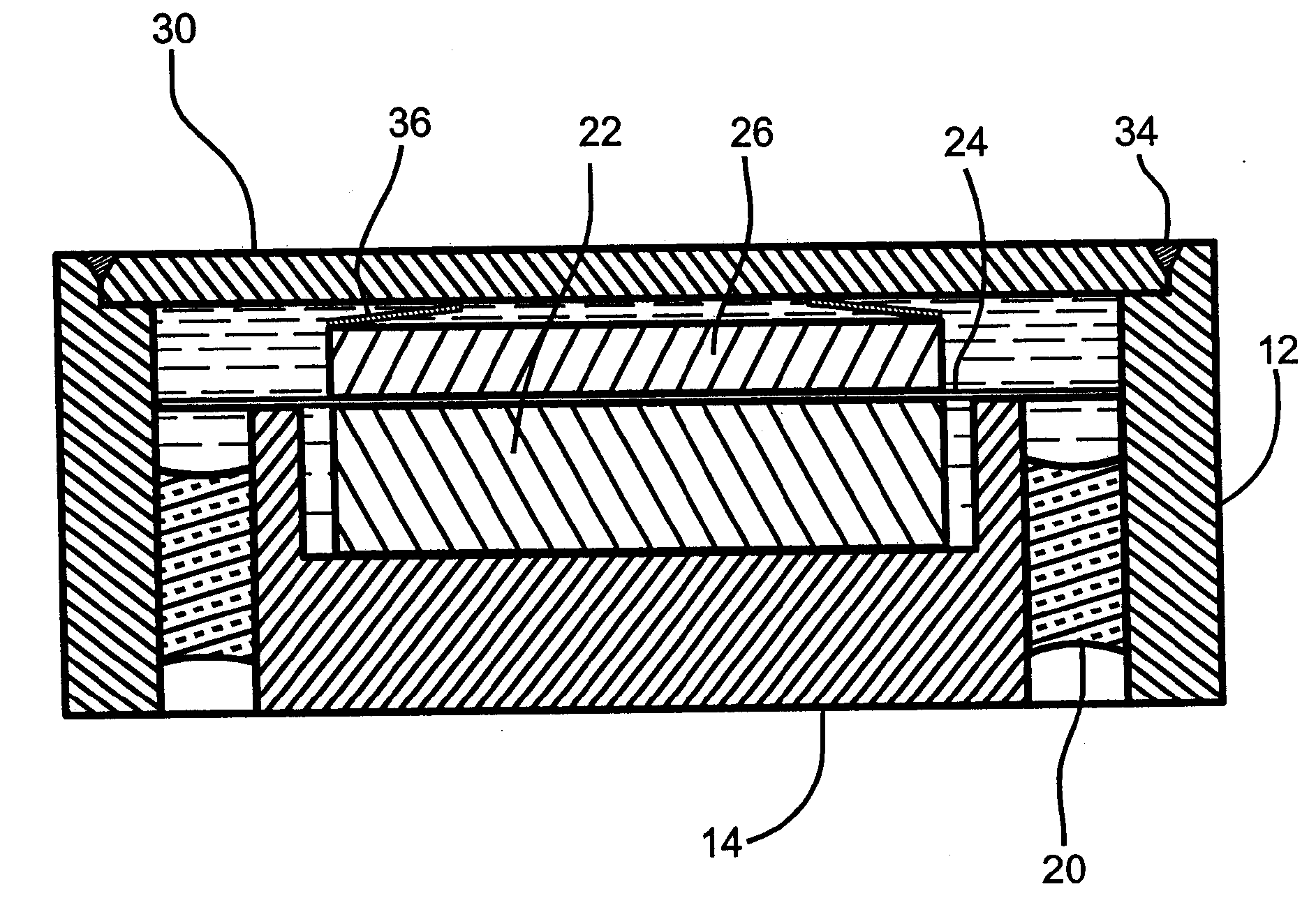

Dual weld plug for an electrochemical cell

ActiveUS10109844B2Reduce the possibilityReduce the overall diameterSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsHermetic sealEngineering

The present invention is directed to an electrochemical cell having plate electrodes housed inside a mating “clamshell” casing. When mated together, the casing components are form-fitting with respect to the internal battery structure so as to reduce the overall size of the electrochemical package. A header assembly containing both a glass-to-metal seal opening for a terminal lead and an electrolyte fill opening is used in conjunction with the clamshell casing. The electrolyte fill opening is constructed with an elongated opening with at least two different radii. A first and second sealing element is welded within the electrolyte fill opening at different depths within the header to block the flow of electrolyte and form a hermetic seal.

Owner:WILSON GREATBATCH LTD

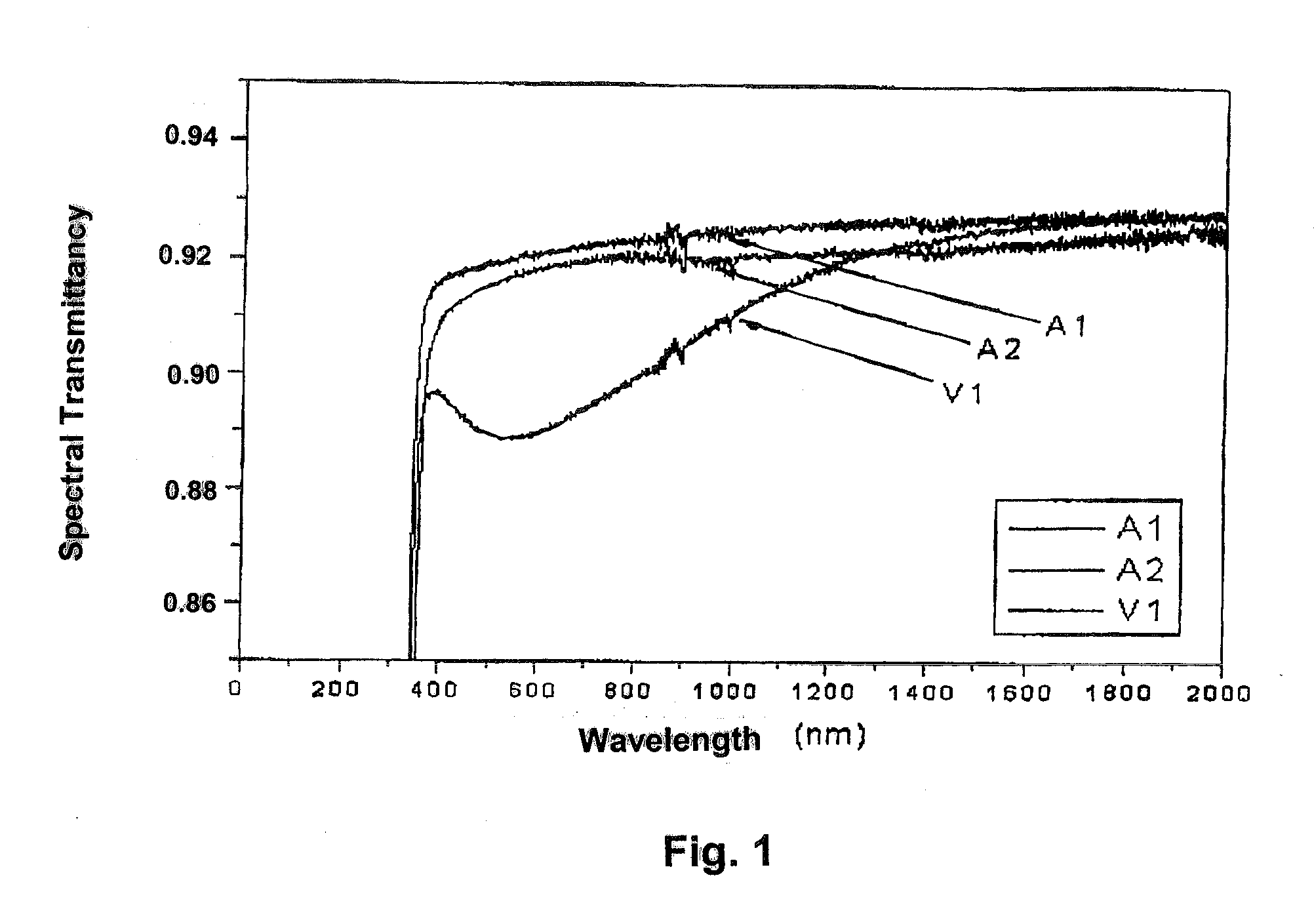

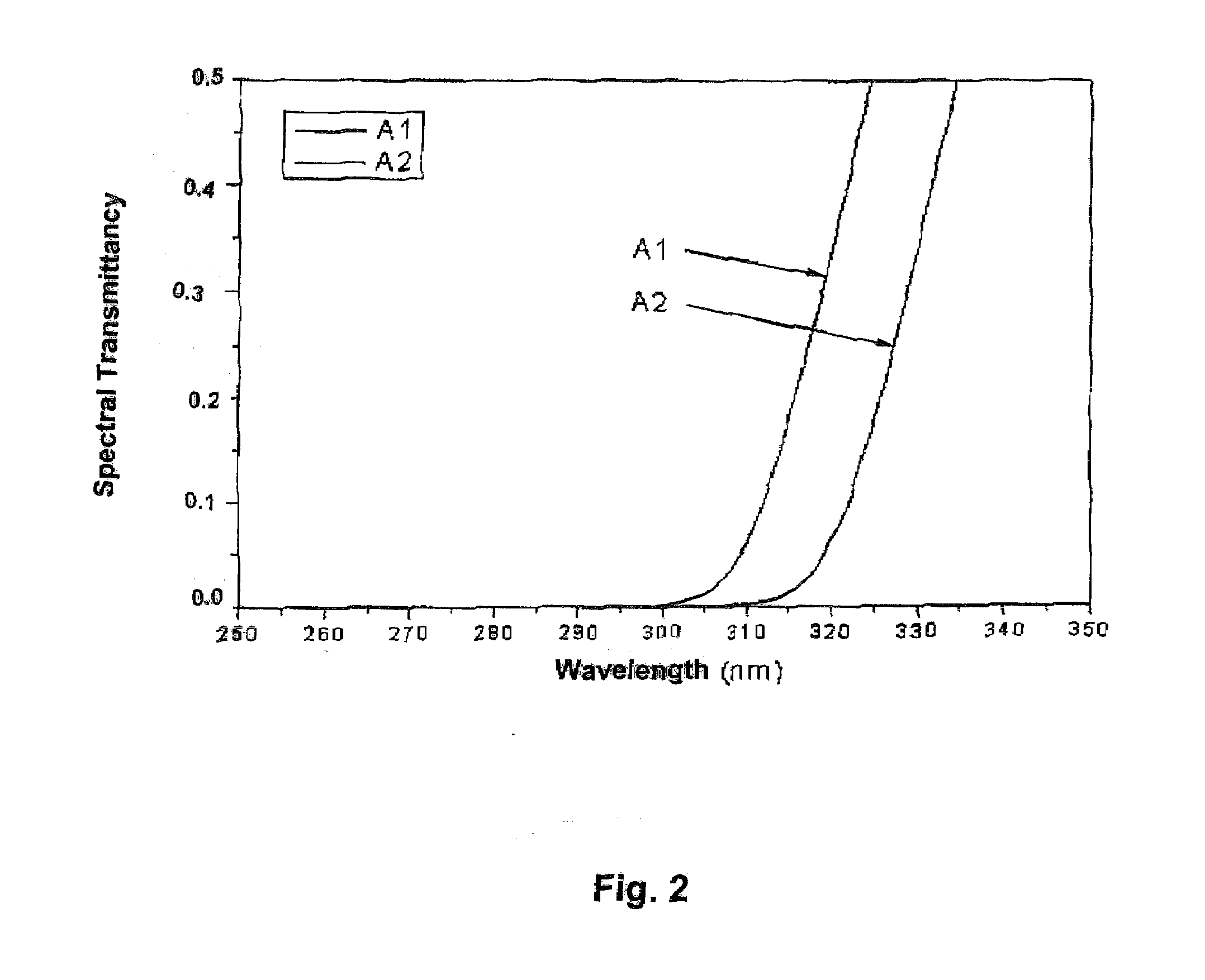

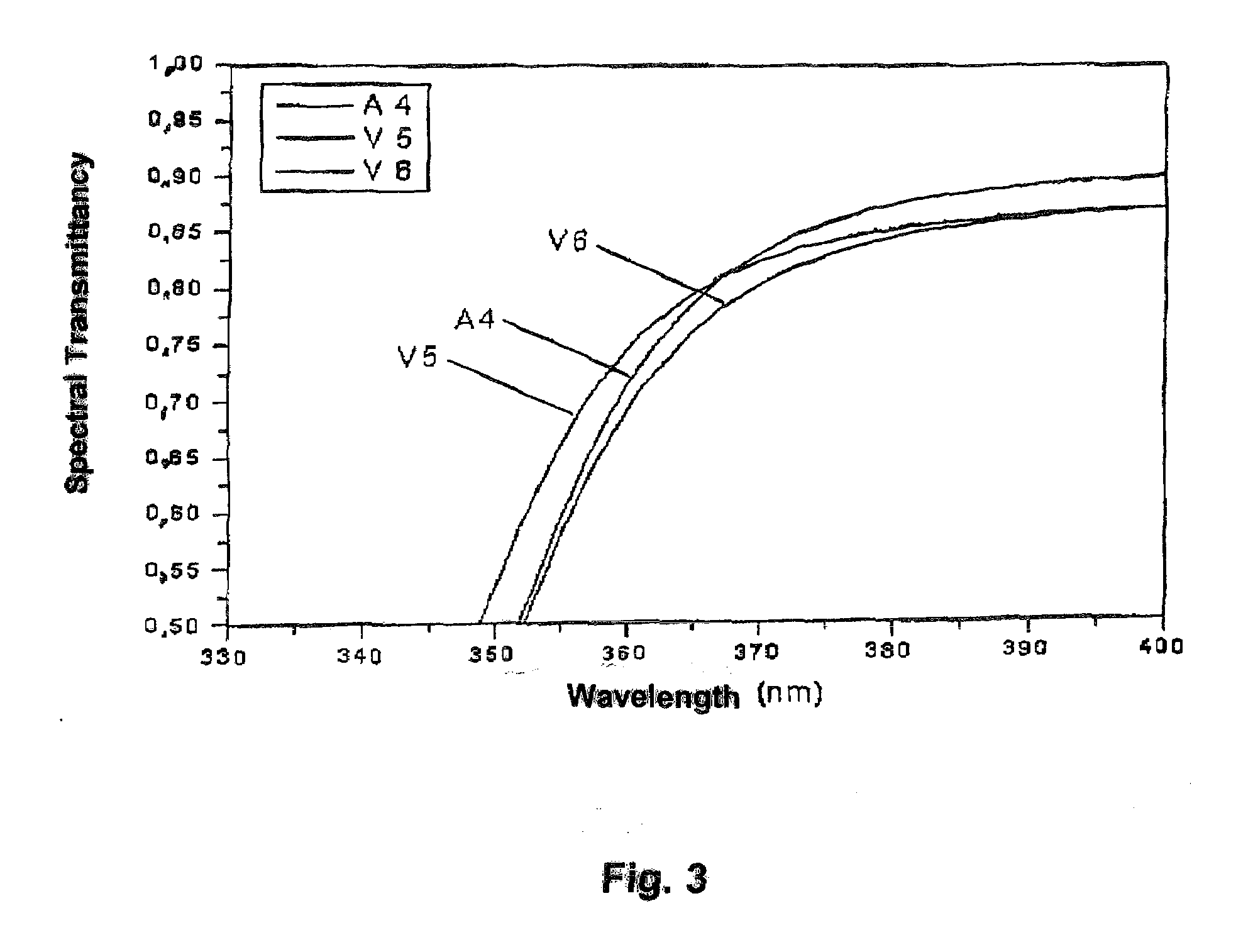

UV-radiation absorbing glass with high chemical resistance, especially for a fluorescent lamp, and methods of making and using same

InactiveUS7491668B2Stable resistanceImprove transmittanceGas discharge lamp detailsGas-discharge lampElectric light

The chemically resistant borosilicate glass has the following composition (in % by weight): SiO2, 67-74; B2O3, 5-10; Al2O3, 3-10; Li2O, 0-4; Na2O, 0-10; K2O, 0-10; MgO, 0-2; CaO, 0-3; SrO, 0-3; BaO, 0-3; ZnO, 0-3; ZrO2, 0-3; CeO2, 0-1; with ΣLi2O+Na2O+K2O=0.5 to 10.5 and ΣMgO+CaO+SrO+BaO+ZnO=0-6. The borosilicate glass is characterized by a composition including 0 to 10% of at least one of TiO2, Bi2O3 and MoO3 and a sum total of TiO2+Bi2O3+MoO3 of 0.1 to 10%. This glass is obtained from the melt under oxidative conditions. The glass is useful in gas discharge lamps, such as Xenon lamps and fluorescent lamps, and display devices, flat structured backlighting devices, and glass-to-metal seals with Mo, Wo and Ni—Fe—Co alloys.

Owner:SCHOTT AG

Uv-radiation absorbing glass with reduced absorption of visible light and method of making and using same

InactiveUS20080254301A1Effectively block UV radiationImprove transmittanceGlass furnace apparatusGlass/slag layered productsColour centreDisplay device

The PbO-free UV-absorbing glass is made under oxidative conditions and has a composition, in % by weight, of: SiO2, 55-79; B2O3, 3-25; Al2O3, 0-10; Li2O, 0-10; Na2O, 0-10; K2O, 0-10; MgO, 0-2; CaO, 0-3; SrO, 0-3; BaO, 0-3; ZnO, 0-3; ZrO2, 0-3; CeO2, 0-1; Fe2O3, 0-1; WO3, 0-3; Bi2O3, 0-3; MoO3, 0-3; ΣLiO+Na2O+K2O=0.5 to 16 and ΣMgO+CaO+SrO+BaO+ZnO=0-10. It also contains from 0.1 to 10% TiO2 with at least 95% of the titanium as Ti+4 so that it has a high visible transmission, reduced color centers, and a sharp UV absorption edge. It is especially useful in lamps display devices and glass-to-metal seals.

Owner:SCHOTT AG

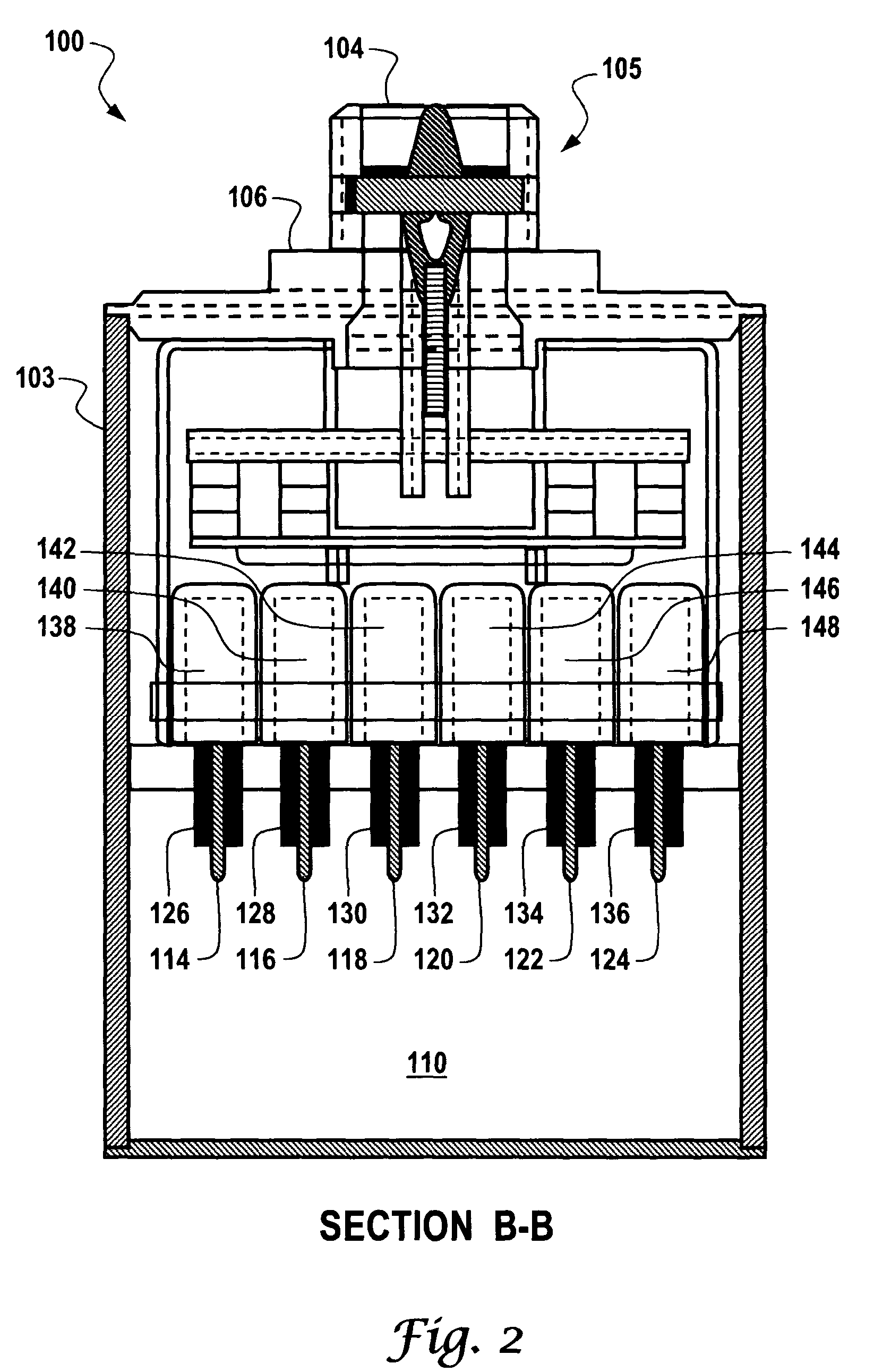

Toggle switch apparatus

InactiveUS6943310B2Additional componentContact mechanismsContact electric connectionToggle switchActuator

A toggle switch apparatus is disclosed, which includes a toggle mechanism and a plurality of basic switches maintained within a tubular housing. An actuator is associated with at least one spring which together can serve to actuate the plurality of basic switches. A lead wire termination assembly can also be configured within the tubular housing, wherein the lead wire termination assembly comprises a plurality of lead wires attached to a plurality of pin contacts that exit through a cover of the tubular housing, thereby permitting the toggle switch apparatus to be actuated manually in a maintained position during high gravity conditions. The tubular housing can be configured as a sealed metal tube. A header can also be sealed into the tubular housing utilizing a glass-to-metal seal.

Owner:HONEYWELL INT INC

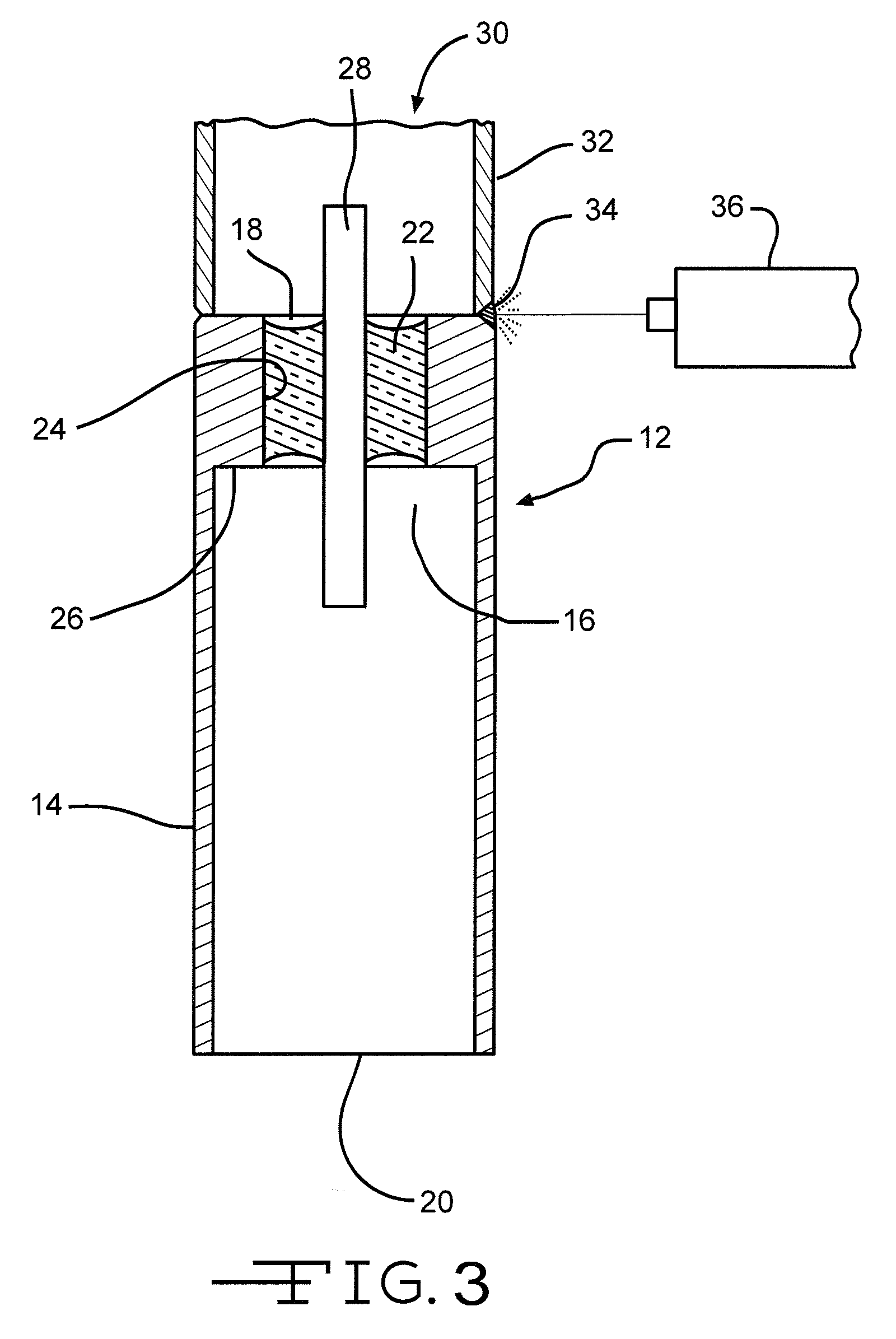

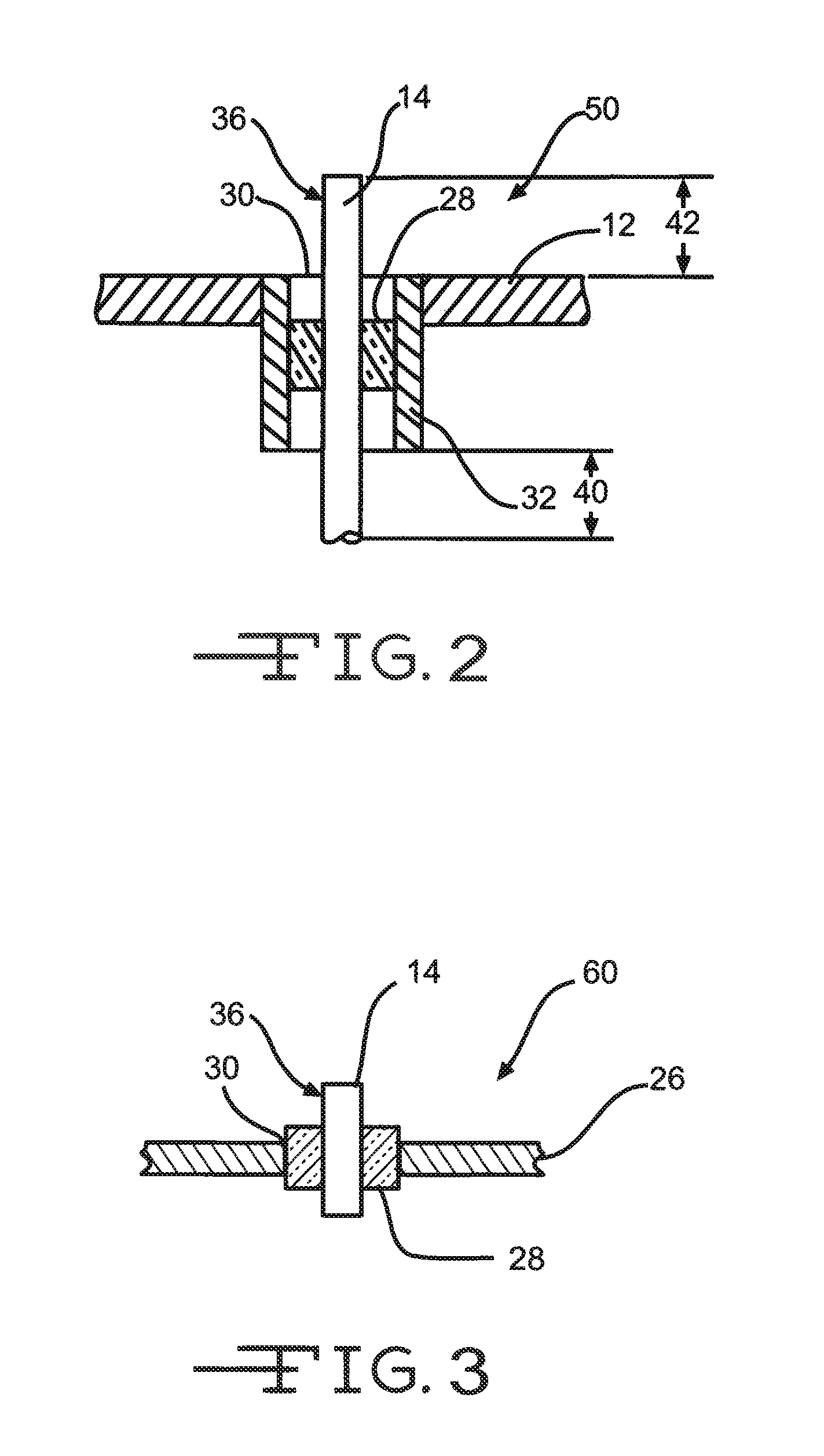

Electric power terminal feed-through

ActiveUS7745725B2Rotary/oscillating piston combinations for elastic fluidsElectrically conductive connectionsEngineeringElectric power

A power terminal feed-through incorporates a metallic body through which extend one or more current conducting pins that are hermetically sealed to the metallic body by a glass-to-metal seal. The metallic body includes an annular lip with a protrusion. During welding installation of the power terminal feed-through, the protrusion serves to assist in the welding process, better controlling the location and definition of the weld between the metallic body and a housing, and to focus the welding heat at the protrusion, thereby protecting the glass-to-metal seal. The glass-to-metal seal can be a single glass insert through which the current conducting pins extend, thereby reducing the pin circle diameter and the overall size of the power terminal feed-through.

Owner:EMERSON ELECTRIC CO

Toggle switch apparatus

InactiveUS20050045464A1Easy to optimizeAdditional componentContact mechanismsContact electric connectionToggle switchEngineering

A toggle switch apparatus is disclosed, which includes a toggle mechanism and a plurality of basic switches maintained within a tubular housing. An actuator is associated with at least one spring which together can serve to actuate the plurality of basic switches. A lead wire termination assembly can also be configured within the tubular housing, wherein the lead wire termination assembly comprises a plurality of lead wires attached to a plurality of pin contacts that exit through a cover of the tubular housing, thereby permitting the toggle switch apparatus to be actuated manually in a maintained position during high gravity conditions. The tubular housing can be configured as a sealed metal tube. A header can also be sealed into the tubular housing utilizing a glass-to-metal seal.

Owner:HONEYWELL INT INC

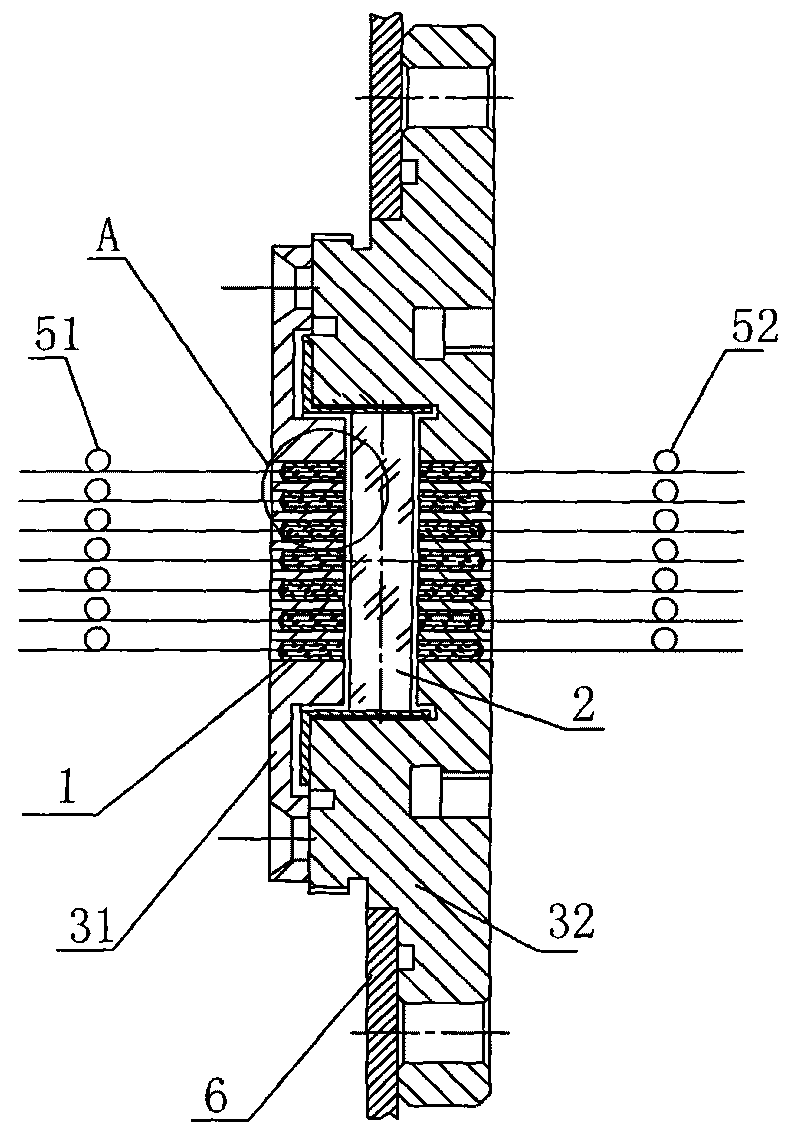

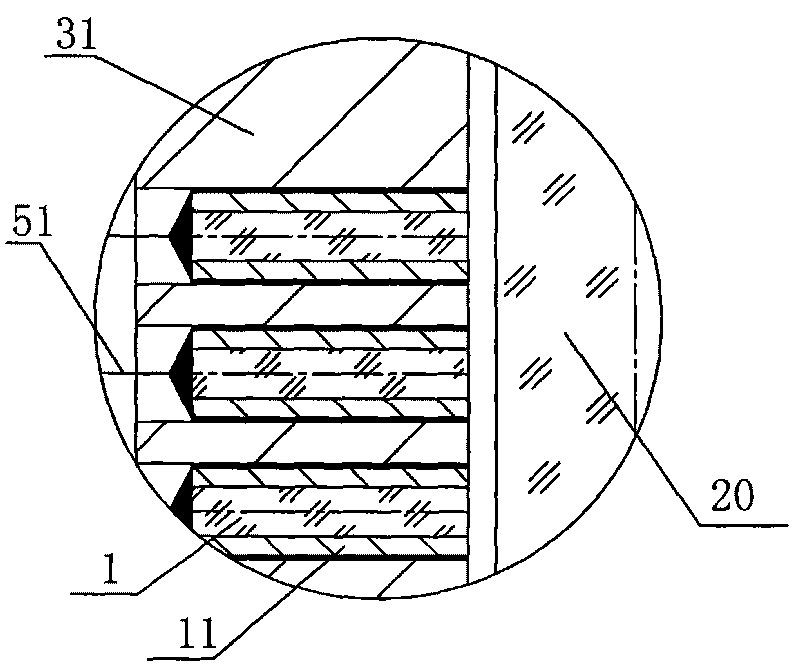

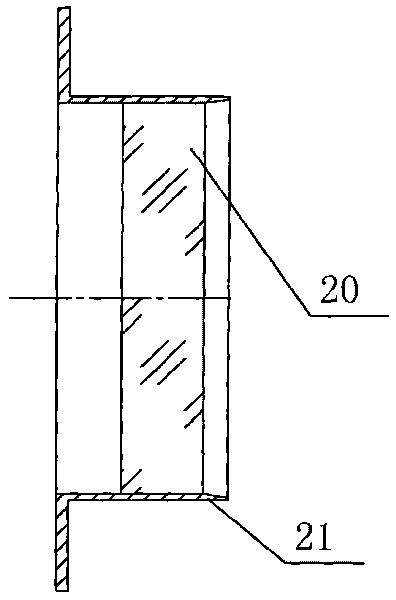

Isolated optical fiber seal switching device and machining method thereof

The invention relates to an isolated optical fiber seal switching device and a machining method thereof. The isolated optical fiber seal switching device comprises an inboard flange, an outboard flange and a glass-to-metal sealing window. The glass-to-metal sealing window is welded on the outboard flange. The inboard flange is fixed with the outboard flange from the inside of a container and clamps the glass-to-metal sealing window between the inboard flange and the outboard flange. The outboard flange is used for being in seal connection with a container interface from the outside of the container. The inboard flange is provided with at least one collimator mounting hole. The outboard flange is provided with collimator mounting holes of which the quantity and position correspond to those of the collimator mounting holes on the inboard flange one by one. The inside of each collimator mounting hole is fixed with an optical fiber collimator. The glass-to-metal seal window comprises optical glass and a thin-wall metal tube with a flanging. The isolated optical fiber seal switching device and the machining method thereof solve the problem that easily-aged organic materials are used to seal an optical fiber, which cannot meet the requirement on seal timeliness in the prior art, and have the advantages of prolonging the service life of sealing equipment and improving the sealing performance.

Owner:NORTHWEST INST OF NUCLEAR TECH

Welded header for pressure transmitter

ActiveUS20080229838A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsEngineeringMechanical engineering

A pressure transmitter comprises a metal wall separating a process pressure chamber from an electronics compartment. The metal wall has a stepped bore with a bore shelf facing the process pressure chamber. A metal header has a stepped outer rim with a header shelf that contacts the bore shelf. The metal header includes at least one electrical feedthrough with a glass-to-metal seal adjacent the stepped outer rim. A welded seal seals the stepped outer rim to the stepped bore.

Owner:ROSEMOUNT INC

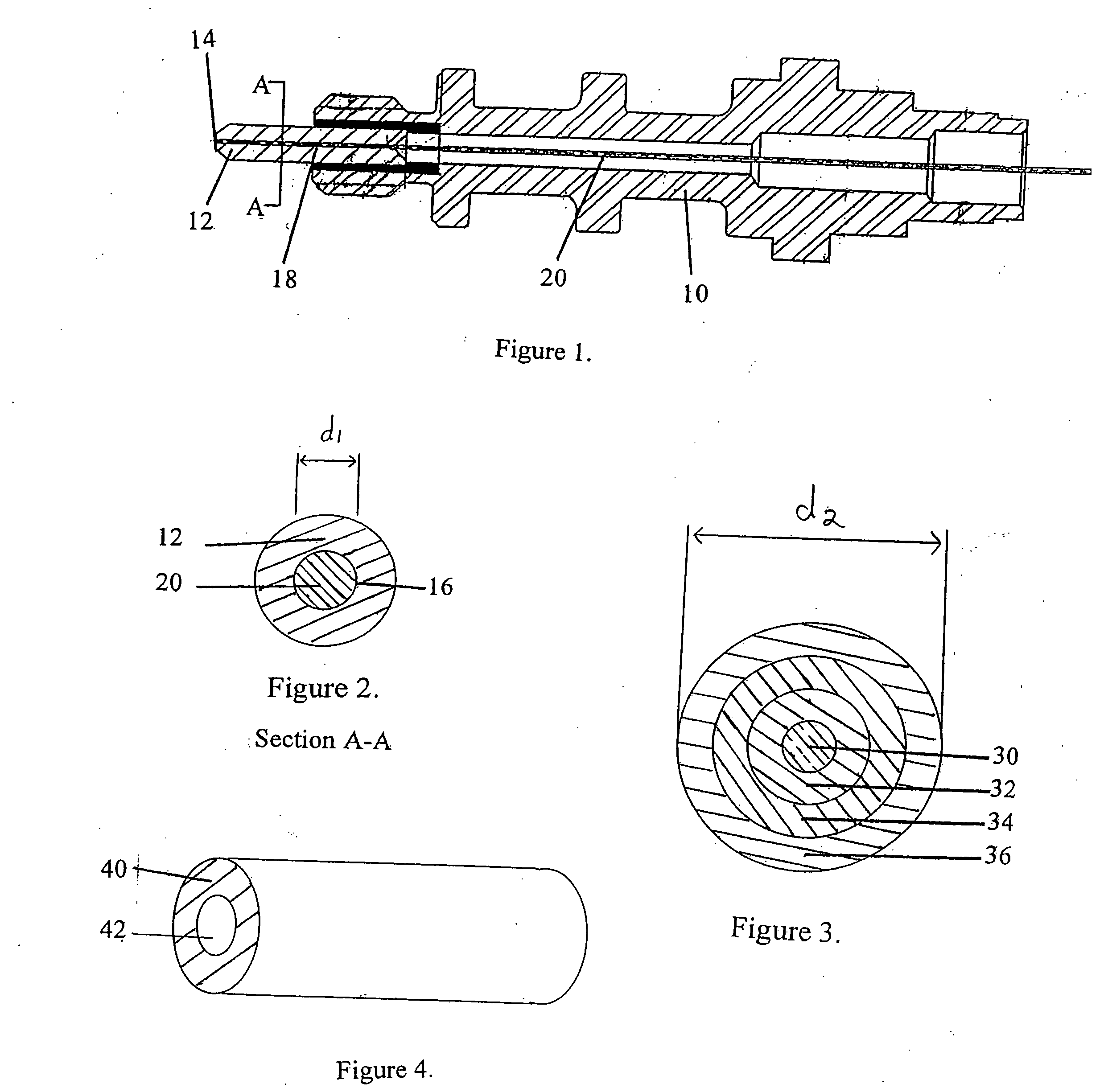

High-pressure/high-temperature seals between glass fibers and metals, downhole optical feedthroughs containing the same, and methods of preparing such seals

ActiveUS20060269211A1High strengthOptical fibre with multilayer core/claddingCoupling light guidesGlass fiberCorrosion resistant alloy

A glass-to-meal seal for use in high temperature and high pressure environments is described. The glass-to-metal seals includes an optical fiber having a metallized portion, the metallized portion having an outer dimension; an object having a high strength, corrosion-resistant alloy, the object having an outer surface and an inner surface defining a bore, the bore having a dimension larger than the outer dimension of the metallized portion of the optical fiber; and a hardened solder material disposed between the metallized portion of the optical fiber and the inner surface of the bore, such that a hermetic seal is provided between the metallized portion of the optical fiber and the inner surface of the bore; wherein the solder includes a substance having a melting temperature greater than about 250° C.

Owner:GREENE TWEED TECH

Novel Method For Gold Plated Termination of Hermetic Device

InactiveUS20150004478A1Efficient and robustImproves cell reliabilityFinal product manufactureCapacitor terminalsElectrochemical cellElectroplating

An electrochemical cell comprising a hermetic glass-to-metal seal utilizing a gold coated terminal lead is described. The surface of the terminal lead is directly coated with a layer of gold utilizing an electroplating method. The improved process improves manufacturing efficiencies and reliability of the electrochemical cell.

Owner:WILSON GREATBATCH LTD

High-pressure/high-temperature seals between glass fibers and metals, downhole optical feedthroughs containing the same, and methods of preparing such seals

ActiveUS7500793B2Optical fibre with multilayer core/claddingCoupling light guidesCorrosion resistant alloyGlass fiber

A glass-to-meal seal for use in high temperature and high pressure environments is described. The glass-to-metal seals includes an optical fiber having a metallized portion, the metallized portion having an outer dimension; an object having a high strength, corrosion-resistant alloy, the object having an outer surface and an inner surface defining a bore, the bore having a dimension larger than the outer dimension of the metallized portion of the optical fiber; and a hardened solder material disposed between the metallized portion of the optical fiber and the inner surface of the bore, such that a hermetic seal is provided between the metallized portion of the optical fiber and the inner surface of the bore; wherein the solder includes a substance having a melting temperature greater than about 250° C.

Owner:GREENE TWEED TECH

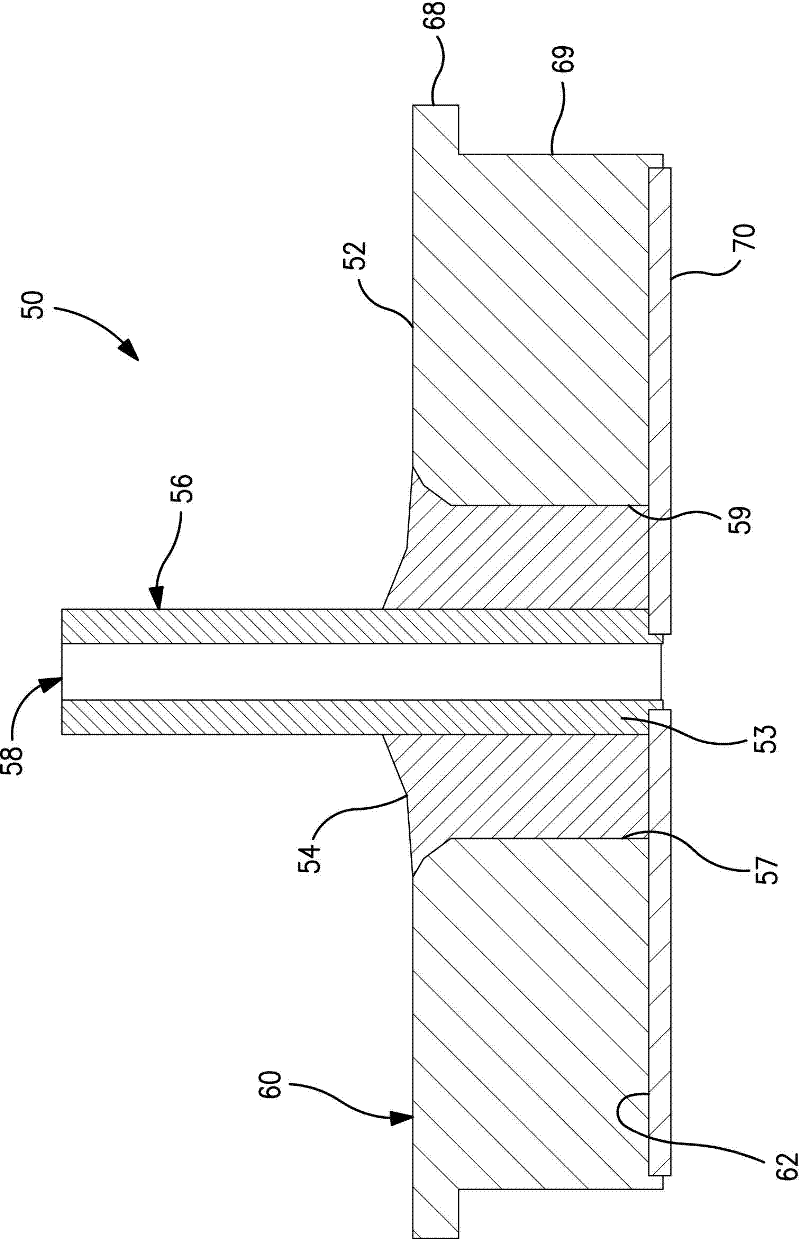

Hermetically Sealed Wet Electrolytic Capacitor

A wet electrolytic capacitor that contains a hermetically sealed lid assembly is disclosed. More specifically, the lid assembly contains a lid (e.g., titanium) that defines an internal orifice. A conductive tube may extend through the orifice that is of a size and shape sufficient to accommodate an anode lead. An insulative material is also provided within the orifice to form a hermetic seal (e.g., glass-to-metal seal), such as between the conductive tube and the lid. The lid assembly also includes a liquid seal that is formed from a sealant material. The liquid seal coats a substantial portion of the lower surface of the lid and hermetic seal to limit contact with any electrolyte that may leak from the casing. To help achieve such surface coverage, the sealant material is generally flowable so that it can be heated during production of the capacitor and flow into small crevices that would otherwise remains uncoated.

Owner:KYOCERA AVX COMPONENTS CORP

Chamber Mount for High Temperature Application of AIN Heaters

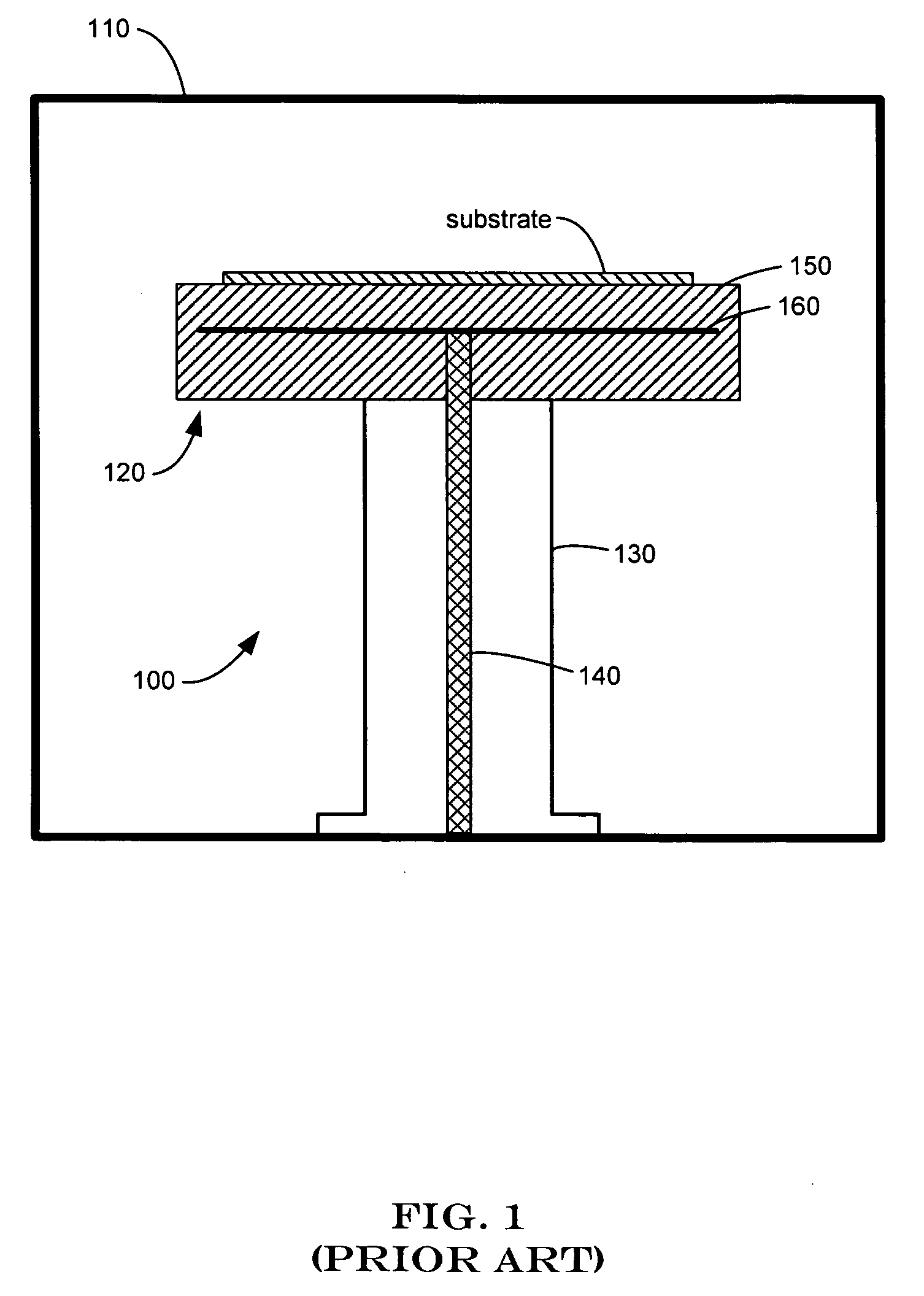

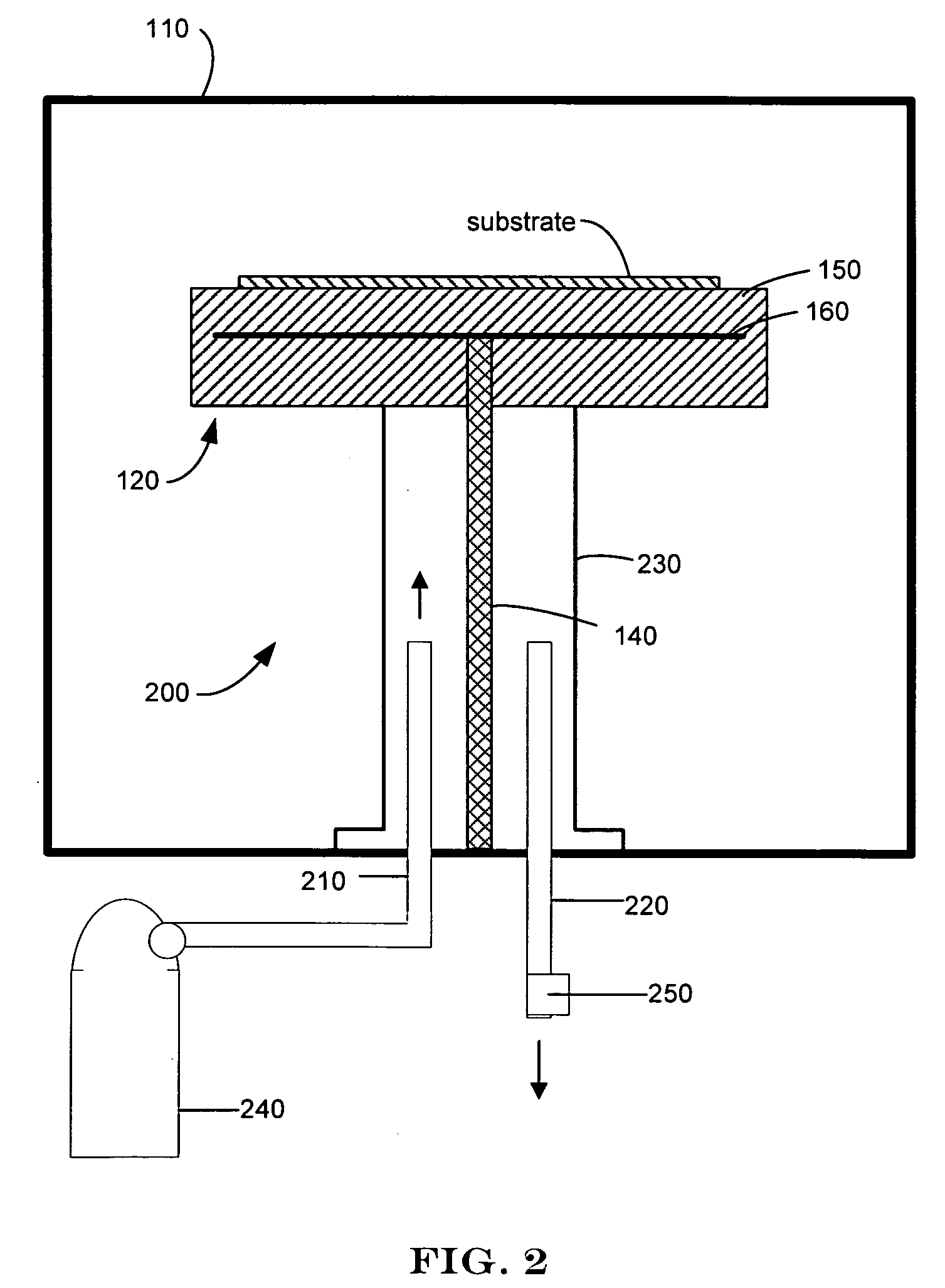

InactiveUS20080314320A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

A susceptor for high temperature semiconductor processing is provided. The susceptor includes a substrate support joined to a hollow shaft having a pair of ports to allow an inert gas to be purged through an internal volume of the shaft. Some embodiments of the susceptor include a chamber mount to support the shaft within a processing chamber and a chamber mount insert disposed within the chamber mount. In these embodiments the chamber mount insert includes the ports. The chamber mount insert can also include a thermocouple tube with a fitting to seal around the thermocouple and to impart an upward pressure to the thermocouple to keep the thermocouple properly seated within the substrate support. The chamber mount insert can also include electrical connectors with glass-to-metal seals.

Owner:COMPONENT RE ENGINEERING COMPANY INC

Hermetically sealed wet electrolytic capacitor

A wet electrolytic capacitor that contains a hermetically sealed lid assembly is disclosed. More specifically, the lid assembly contains a lid (e.g., titanium) that defines an internal orifice. A conductive tube may extend through the orifice that is of a size and shape sufficient to accommodate an anode lead. An insulative material is also provided within the orifice to form a hermetic seal (e.g., glass-to-metal seal), such as between the conductive tube and the lid. The lid assembly also includes a liquid seal that is formed from a sealant material. The liquid seal coats a substantial portion of the lower surface of the lid and hermetic seal to limit contact with any electrolyte that may leak from the casing. To help achieve such surface coverage, the sealant material is generally flowable so that it can be heated during production of the capacitor and flow into small crevices that would otherwise remains uncoated.

Owner:KYOCERA AVX COMPONENTS CORP

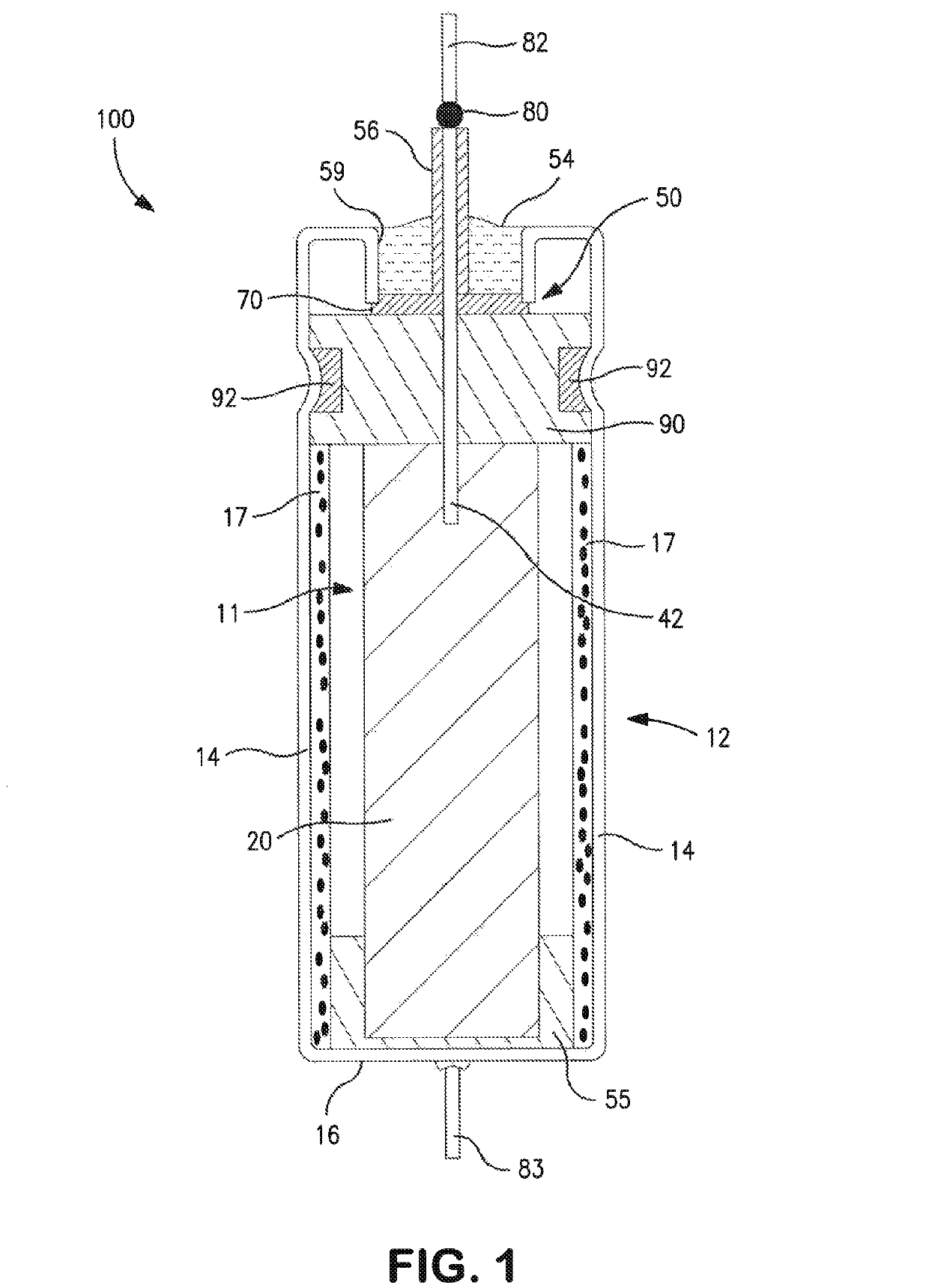

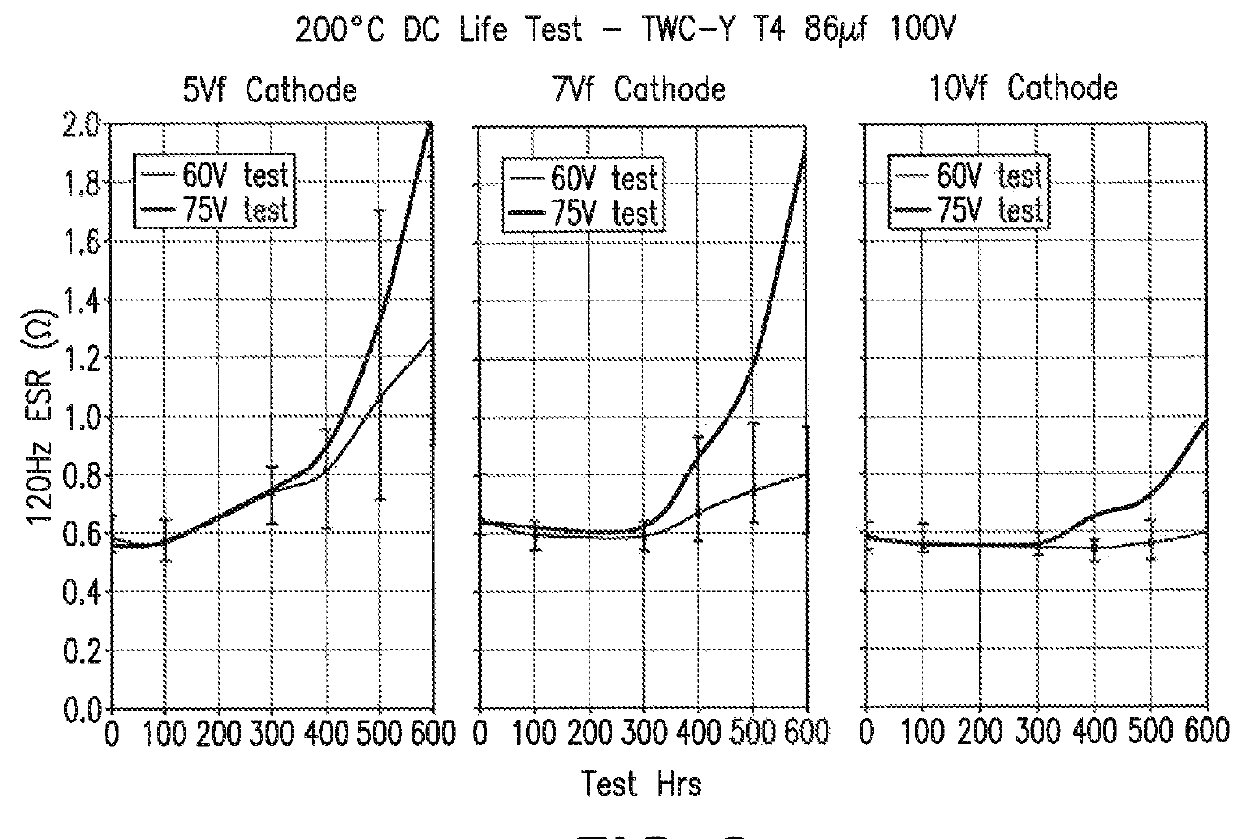

Wet Electrolytic Capacitor for Use at High Temperatures

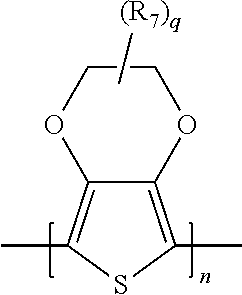

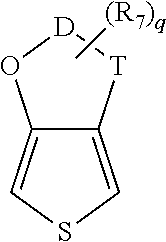

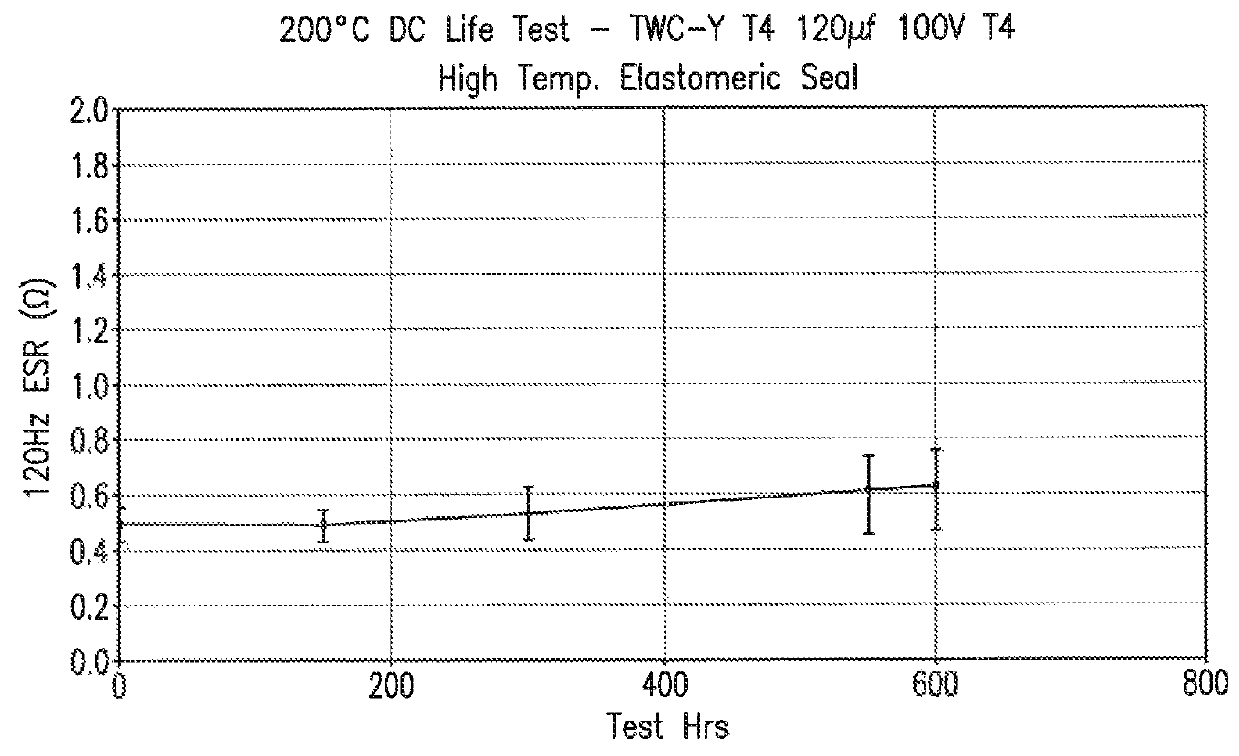

A wet electrolytic capacitor that contains an anode formed from an anodically oxidized sintered porous body and a fluidic working electrolyte is provided. The casing contains a metal substrate coated an electrochemically-active material. Through a unique and controlled combination of features relating to the capacitor configuration and sealing assembly, the present inventor has discovered that good electrical properties (e.g., ESR stability) can be achieved at relatively high temperatures. One unique feature of the wet electrolytic capacitor that can help achieve such good ESR stability is the presence of a dielectric layer on the metal substrate of the cathode within a controlled thickness range. In other embodiments, a sealing assembly may be employed that contains a hermetic seal (e.g., glass-to-metal seal) and an elastomeric barrier seal formed from a high-temperature elastomeric material.

Owner:KYOCERA AVX COMPONENTS CORP

Wet electrolytic capacitor for use at high temperatures

A wet electrolytic capacitor that contains an anode formed from an anodically oxidized sintered porous body and a fluidic working electrolyte is provided. The casing contains a metal substrate coated an electrochemically-active material. Through a unique and controlled combination of features relating to the capacitor configuration and sealing assembly, the present inventor has discovered that good electrical properties (e.g., ESR stability) can be achieved at relatively high temperatures. One unique feature of the wet electrolytic capacitor that can help achieve such good ESR stability is the presence of a dielectric layer on the metal substrate of the cathode within a controlled thickness range. In other embodiments, a sealing assembly may be employed that contains a hermetic seal (e.g., glass-to-metal seal) and an elastomeric barrier seal formed from a high-temperature elastomeric material.

Owner:KYOCERA AVX COMPONENTS CORP

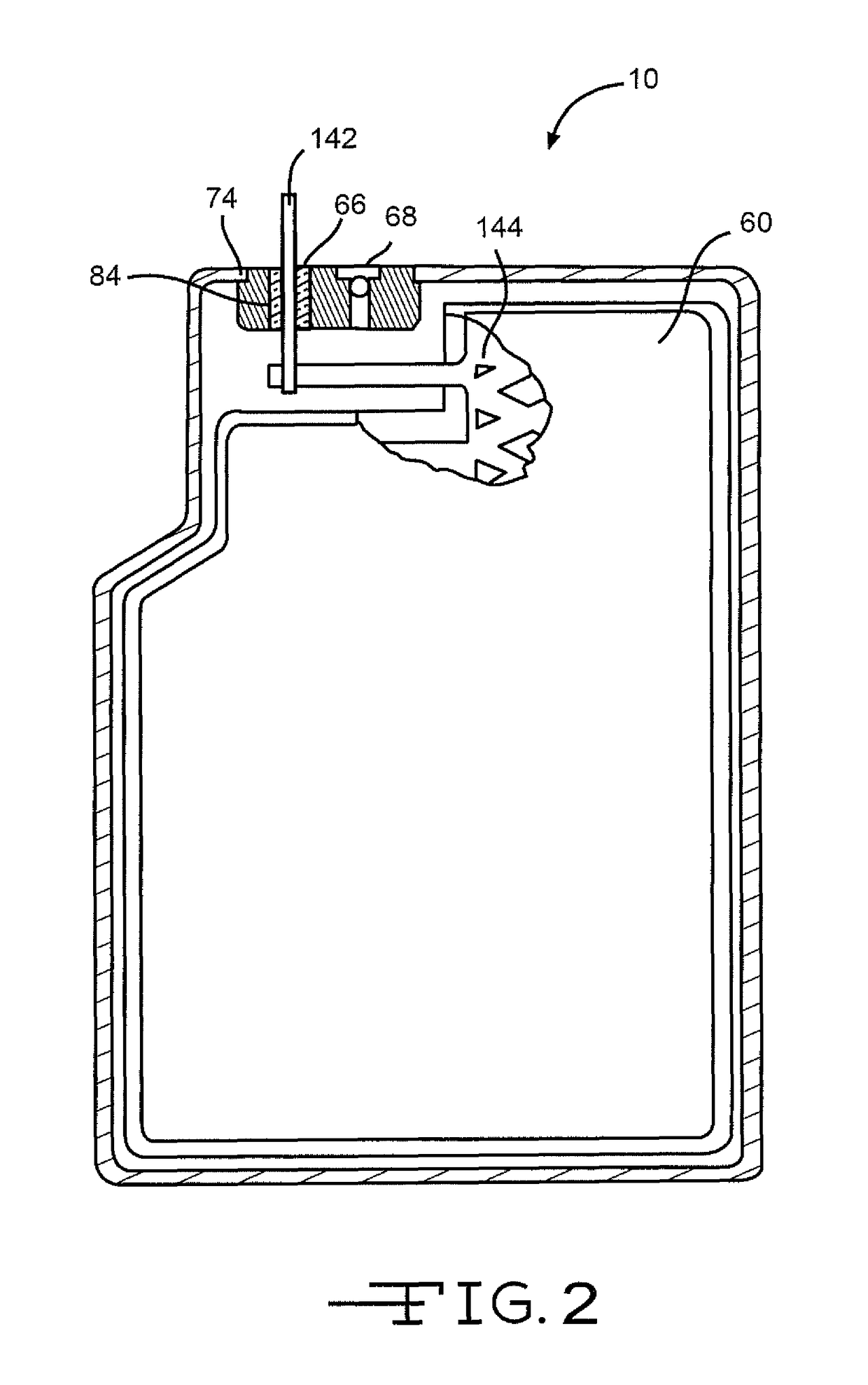

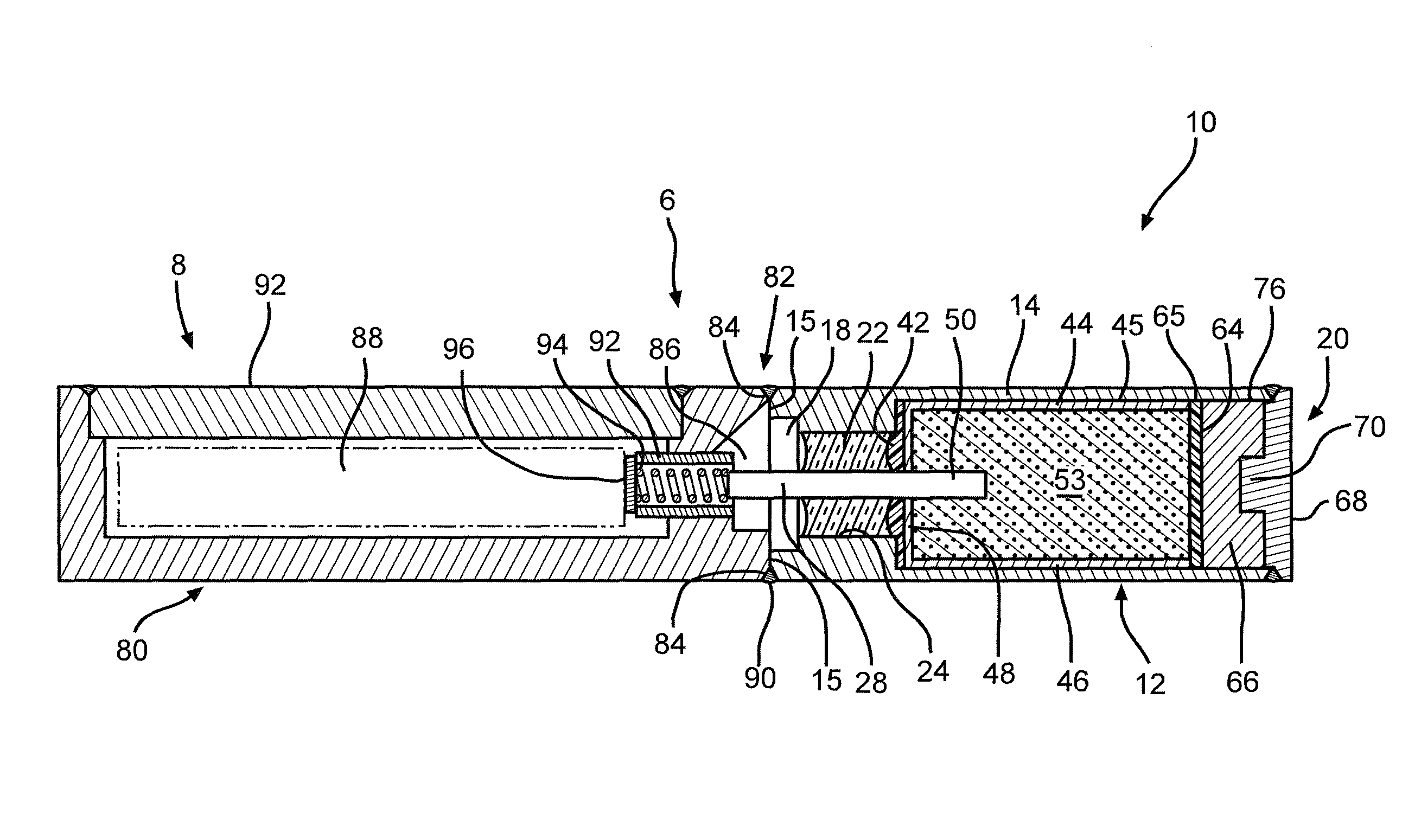

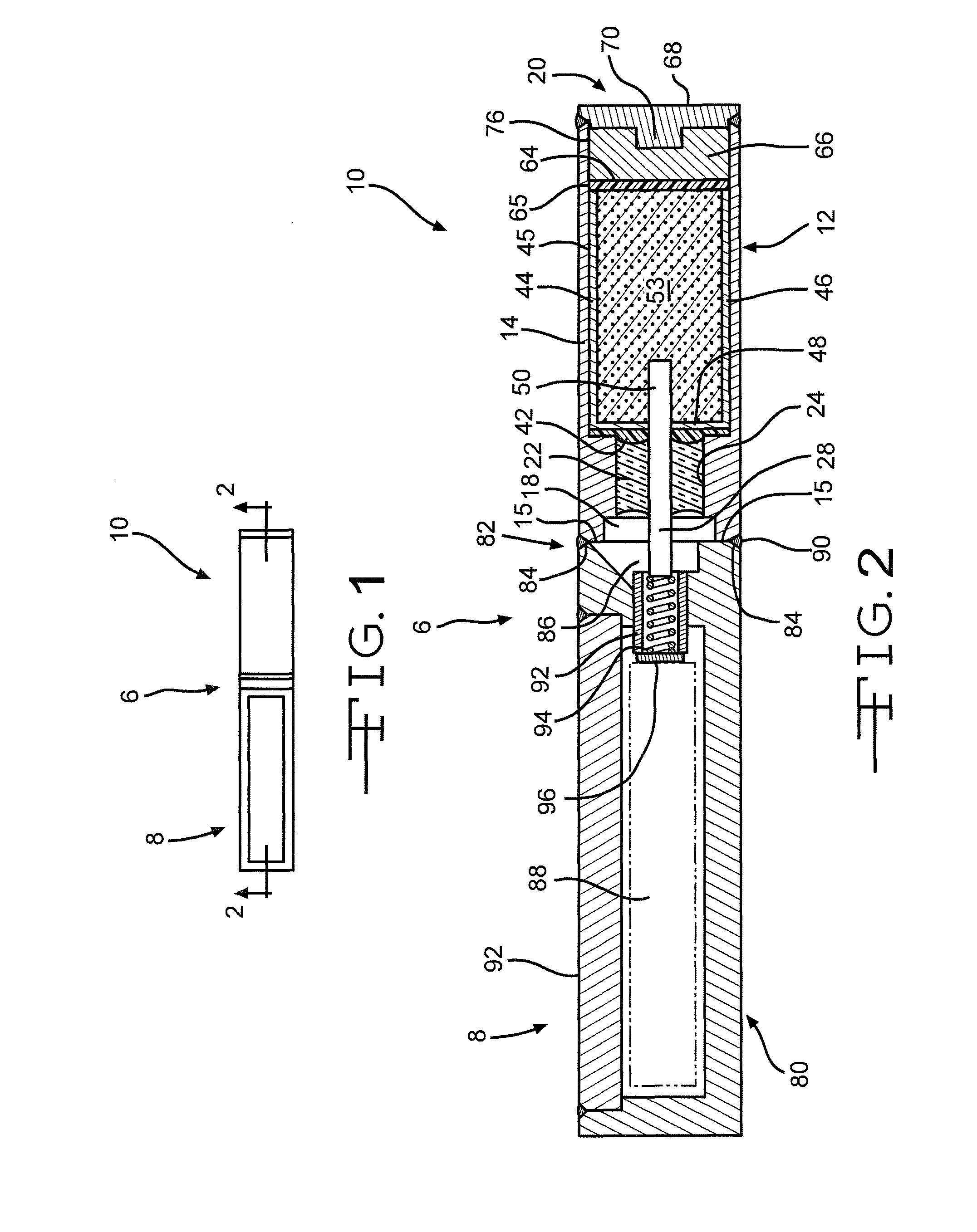

Implantable medical assembly

A compact implantable medical assembly is comprised of a medical device connected to an electrochemical cell. The medical device is comprised of a housing enclosing at least one electrical circuit and including an end having a perimeter edge and a contact opening therethrough. The electrochemical cell is comprised of a casing having a sidewall extending to a distal end and a proximal end forming a proximal opening. The proximal casing end is joined to the medical device housing. A glass-to-metal seal supports a terminal pin extending from within the casing through the proximal casing opening and through the contact opening in the end of the housing. The terminal pin is connected to the electrical circuit contained within the housing. That way the cell serves as the power source for the medical device with both the cell and medical device being exposed to body fluid.

Owner:WILSON GREATBATCH LTD

Hermetically sealed wet electrolytic capacitor

The invention discloses a wet electrolytic capacitor that contains a hermetically sealed lid assembly. More specifically, the lid assembly contains a lid (e.g., titanium) that defines an internal orifice. A conductive tube may extend through the orifice that is of a size and shape sufficient to accommodate an anode lead. An insulative material is also provided within the orifice to form a hermetic seal (e.g., glass-to-metal seal), such as between the conductive tube and the lid. The lid assembly also includes a liquid seal that is formed from a sealant material. The liquid seal coats a substantial portion of the lower surface of the lid and hermetic seal to limit contact with any electrolyte that may leak from the casing. To help achieve such surface coverage, the sealant material is generally flowable so that it can be heated during production of the capacitor and flow into small crevices that would otherwise remain uncoated.

Owner:AVX CORP

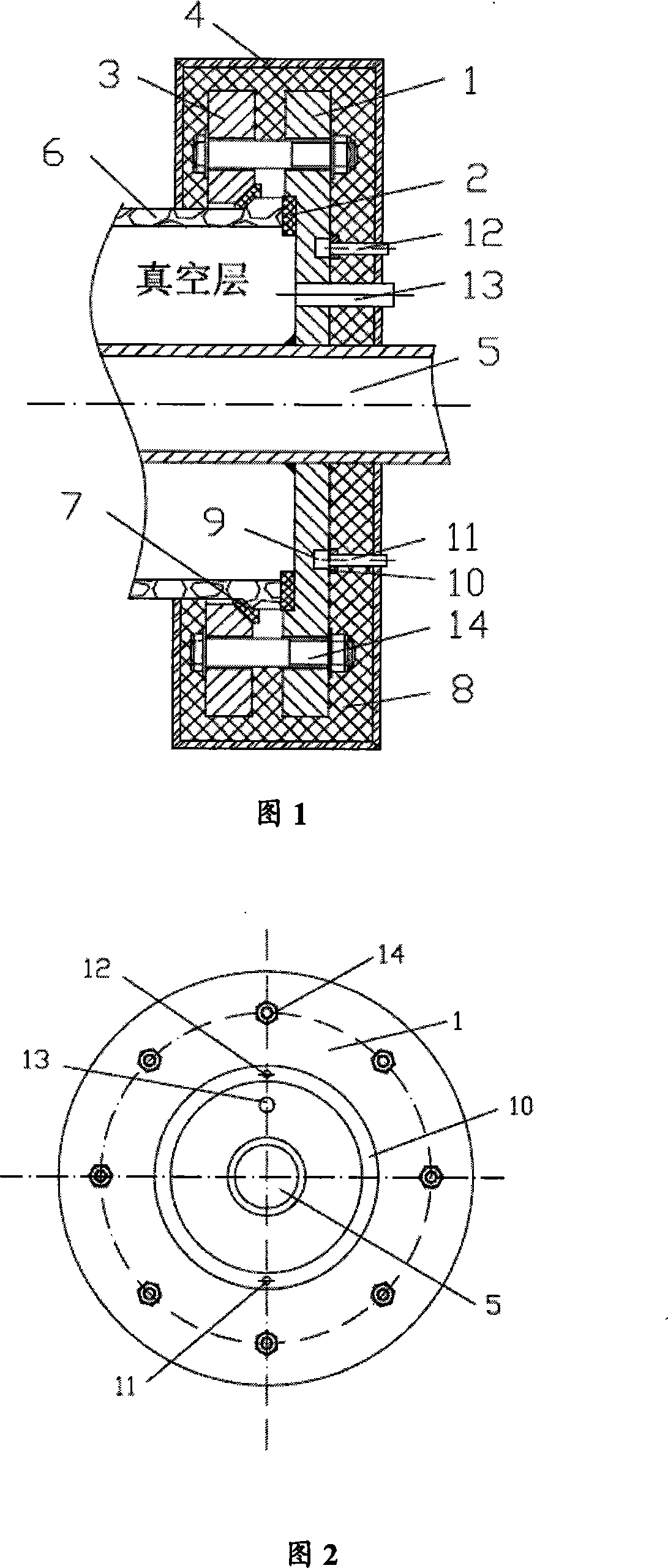

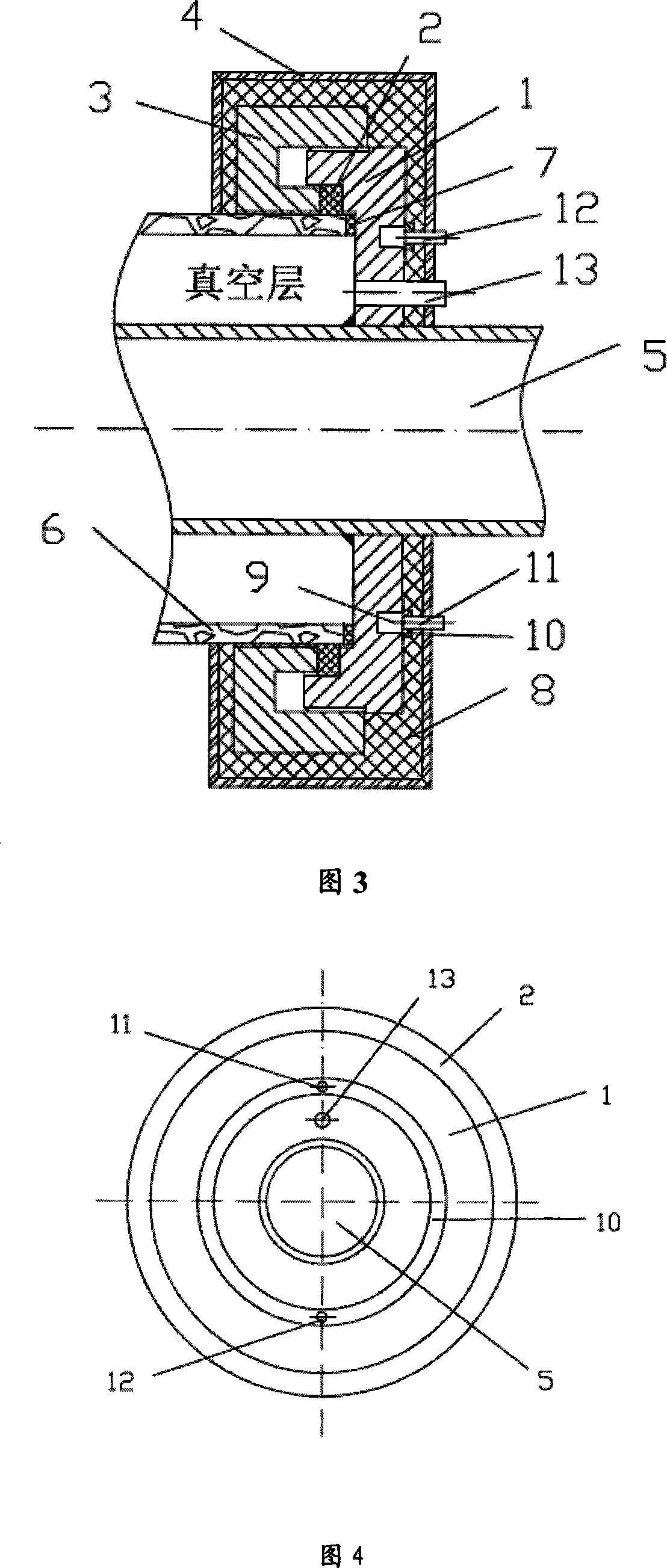

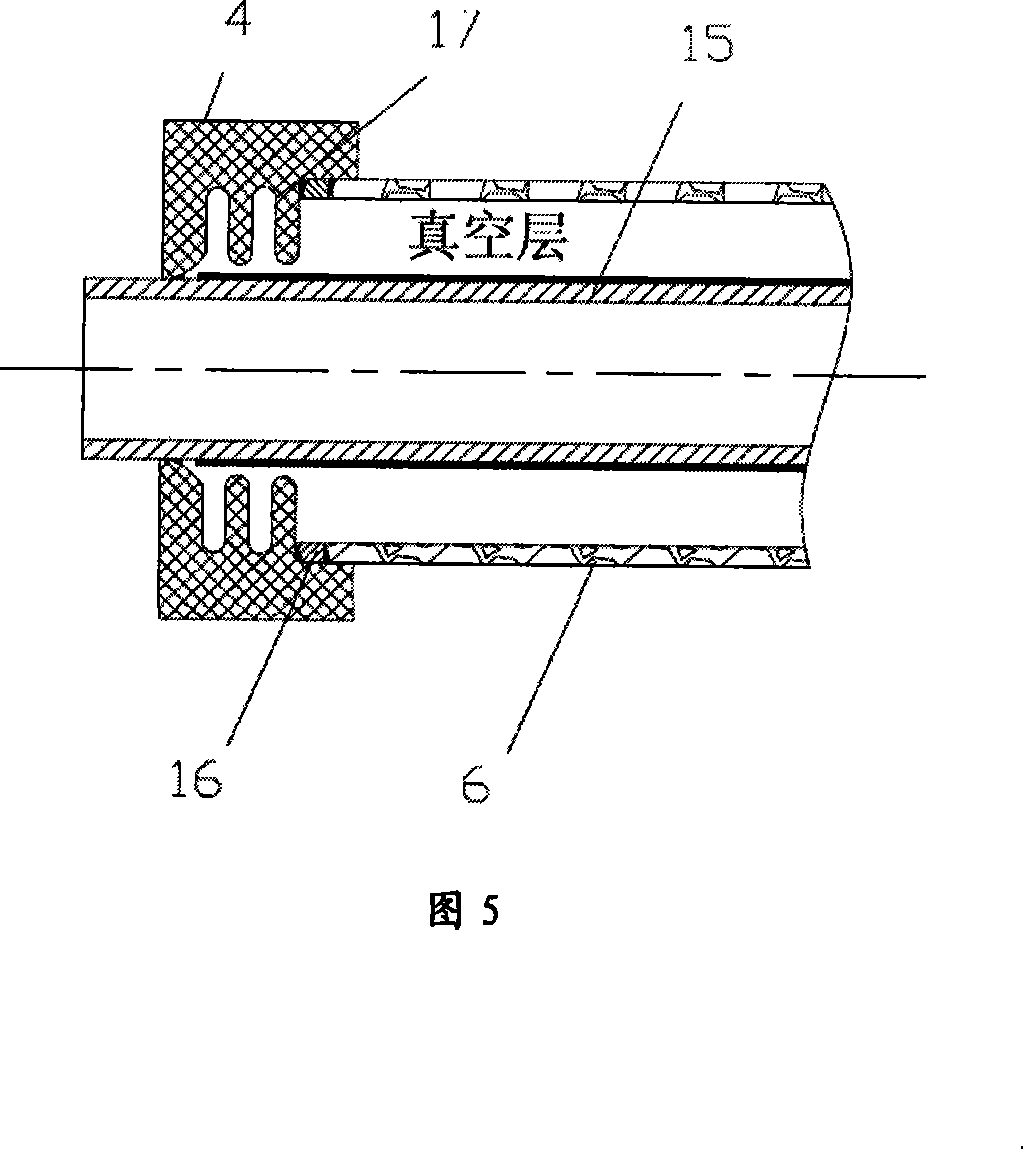

Glass metal sealing device of intermediate temperature solar heat pipe receivers

InactiveCN101178258AExtended service lifeAvoid damageSolar heating energySolar heat devicesExpansion jointOperating temperature

The invention relates to a glass-metal sealing device for a medium-temperature solar heat pipe receiver. The structure of the present invention is that the heat pipe passes through the center of the metal cover plate and is sealed and welded with the metal cover plate. In the vacuum layer, an annular cooling groove is opened on the outside of the metal cover plate, and the shielding cover is arranged outside the sealing place. The invention solves the defects of the sealing structure of the parabolic trough receiver that the expansion coefficients of the glass-metal sealing parts should be strictly matched, too many solder joints, poor reliability, difficult processing and high price. The invention can sealingly connect glass and metal whose expansion coefficients do not match. There is a cooling water tank on the cover plate. When the working temperature of the receiver is 400°C, the temperature of the sealing ring is still lower than 200°C, which prolongs the life of the sealing device and will not cause deformation. Different thermal stress is generated, no expansion joint is required, the structure is simple, the processing is convenient, and the cost is low.

Owner:NANJING UNIV OF TECH

Hermetic glass-to-metal seal assembly and method of manufacturing hermetic glass-to-metal seal assembly

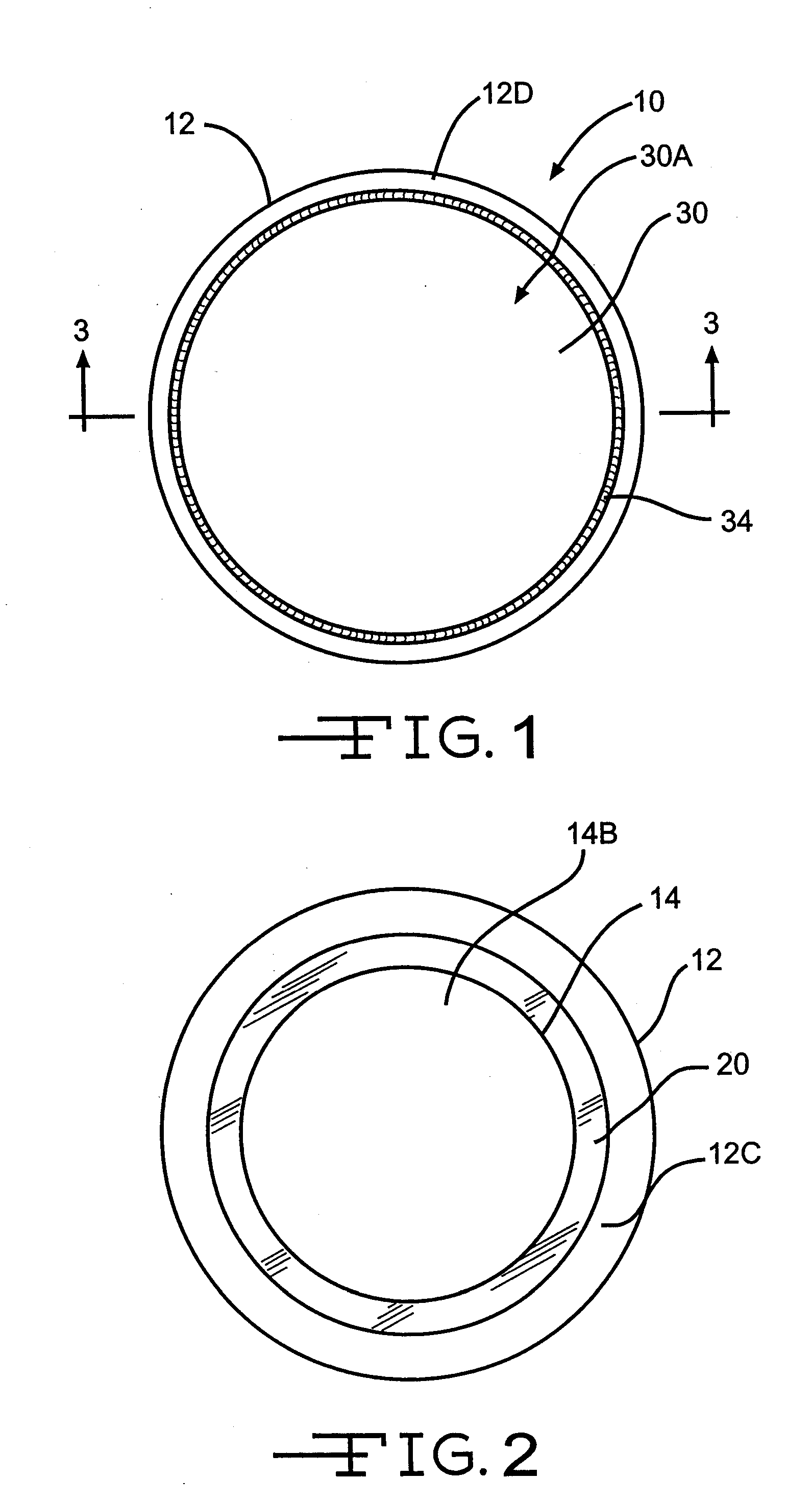

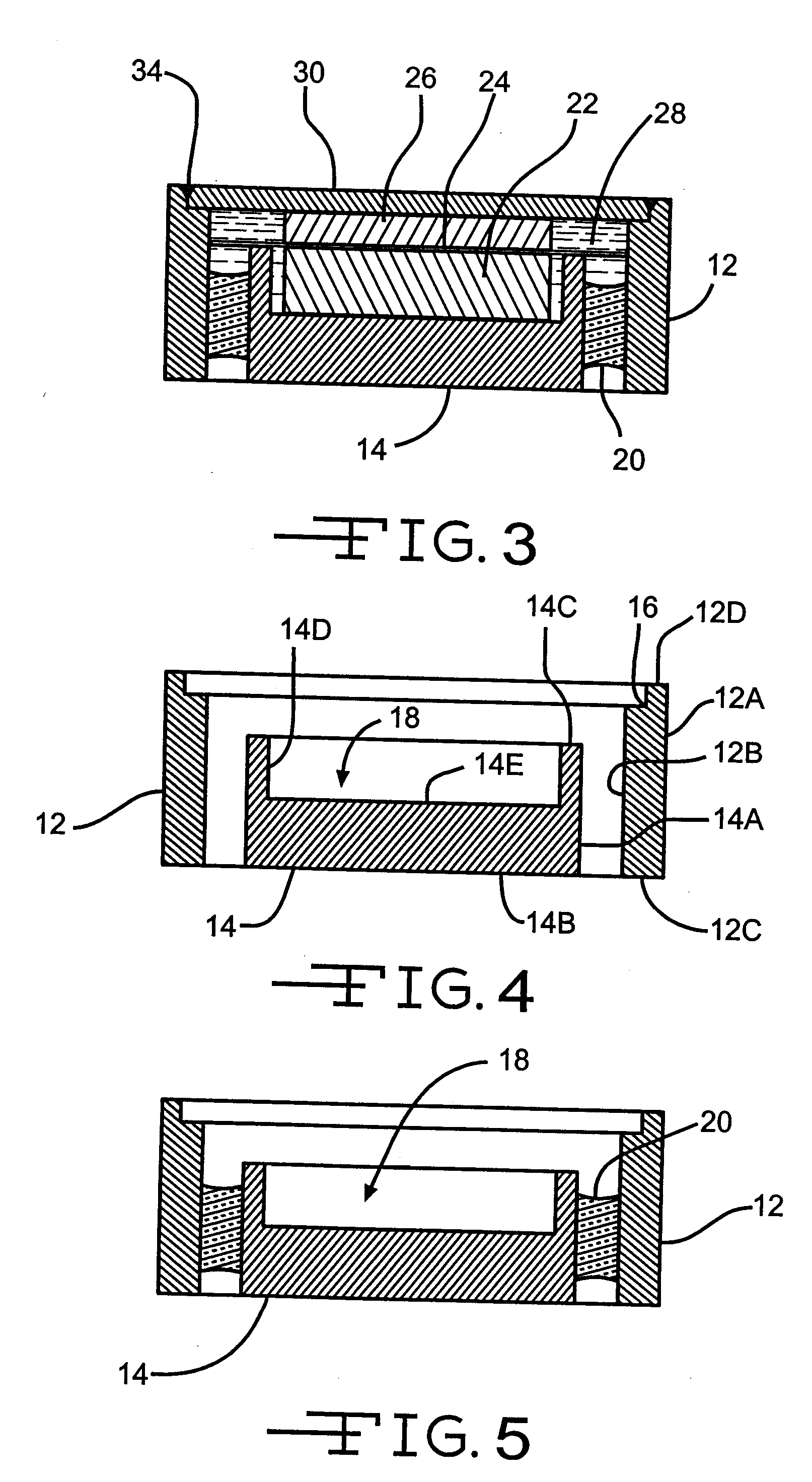

A glass-to-metal hermetic seal assembly in a sight glass assembly or a hermetic terminal assembly is disclosed and includes a glass component, an intermediate component, and an outer ring. The intermediate component is provided around the glass component. The glass component is fused to the intermediate component. The outer ring, which has a coefficient of thermal expansion that is greater than a coefficient of thermal expansion of the glass component, compresses the intermediate component against the glass component to create a hermetic compression seal.

Owner:EMERSON ELECTRIC CO

Cryogenic grinding of tantalum for use in capacitor manufacture

InactiveUS20160336115A1Easy millingExemption stepsLiquid electrolytic capacitorsCapacitor electrodesElectrolysisEngineering

An electrolytic capacitor comprising an anode comprised of cryogenically milled anode material is described. The cryogenic milling process prepares the active anode material for anode fabrication. The capacitor further comprises a casing of first and second casing members secured to each other to provide an enclosure. A feedthrough electrically insulated from the casing and from the casing and extending there from through a glass-to-metal seal, at least one anode electrically connected within the casing, a cathode, and an electrolyte. The cathode is of a cathode active material deposited on planar faces of the first and second casing members.

Owner:WILSON GREATBATCH LTD

Method for providing a hermetically sealed coin cell

ActiveUS20060037190A1Firmly connectedEasy to mountFinal product manufactureElectrode carriers/collectorsTelecommunicationsCoin cell

A hermetically sealed coin cell is described. The coin cell has the opposite polarity terminals isolated from one another by a glass-to-metal seal. Glassing a conductive disc inside a ring of greater diameter and height forms this seal. The height of the ring is equivalent to the desired height of the cell. The disc acts as one cell terminal, which can be positive or negative, and the ring serves as the other terminal. In plan view, both terminals are on the same side of the cell. This allows for easy mounting and connection to an electronic circuit board, and the like.

Owner:WILSON GREATBATCH LTD

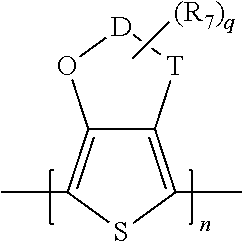

Feed-through

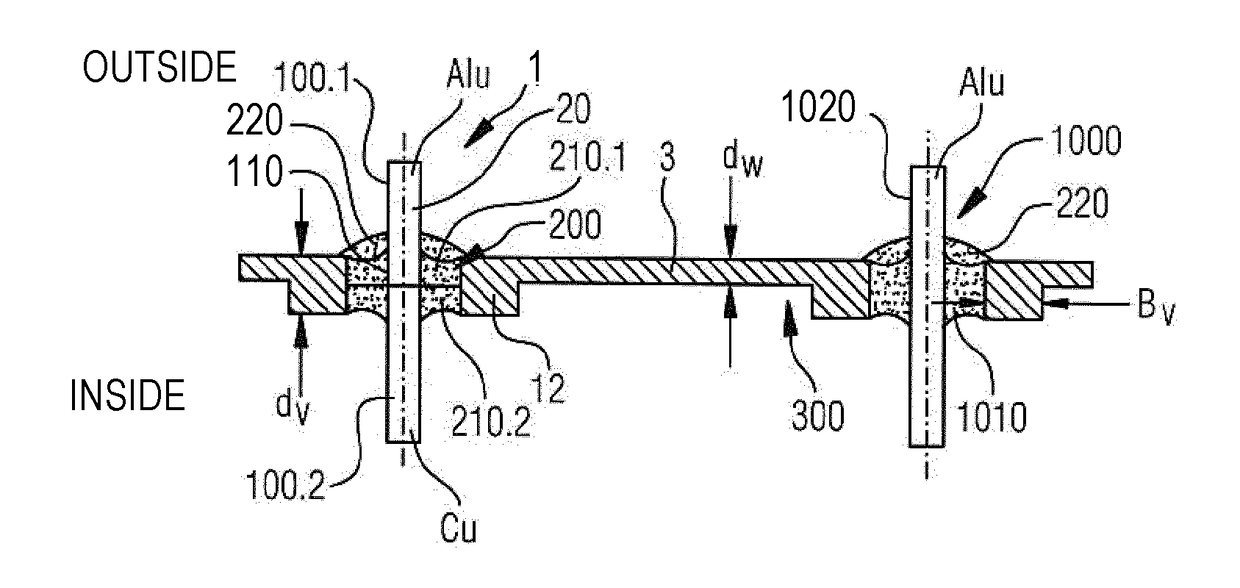

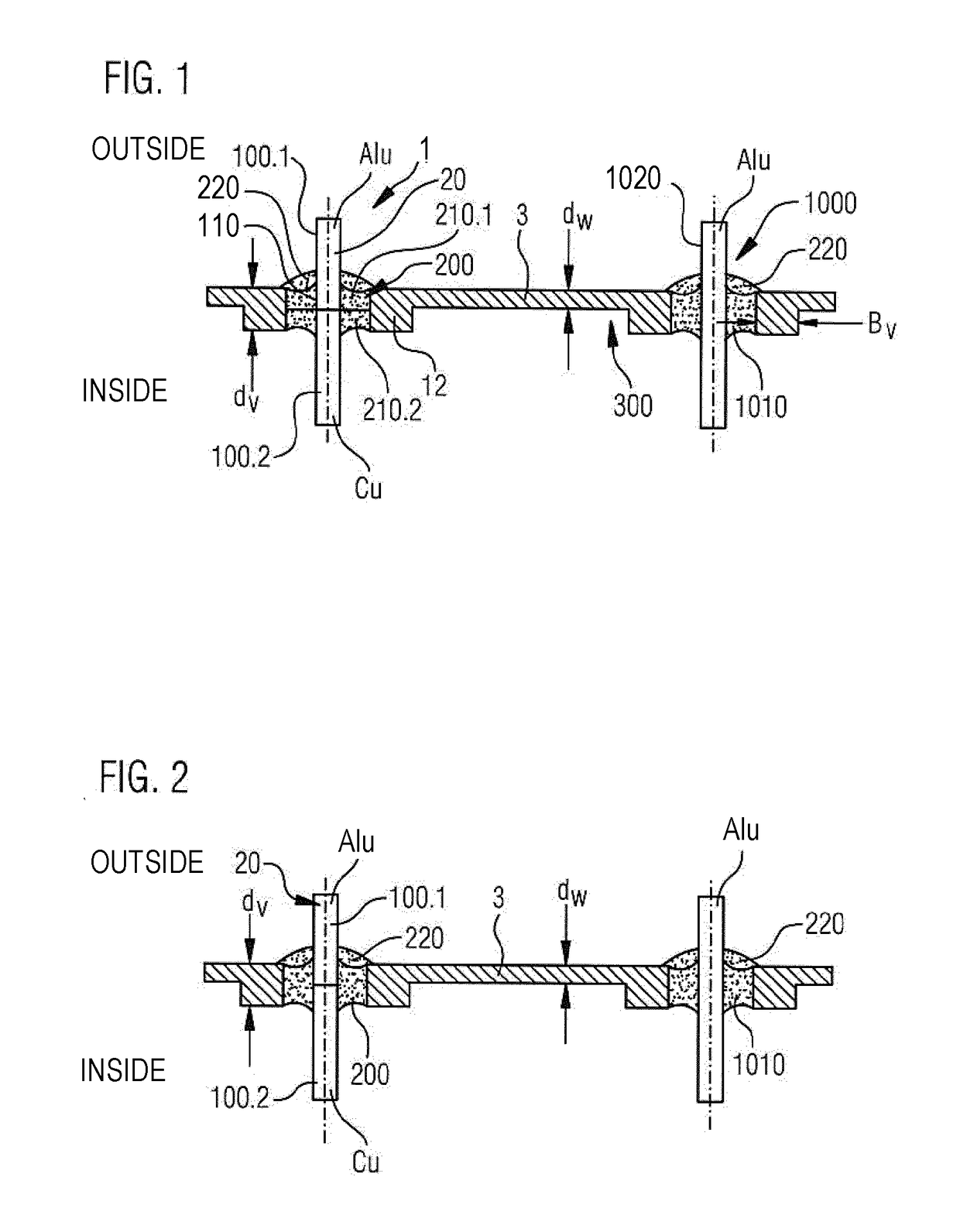

ActiveUS20170222195A1Easy interconnectionAvoid contact corrosionCapacitor housing/encapsulationLi-accumulatorsElectrical conductorCopper

A feed-through through a housing part of a housing, for example of a battery or a capacitor made of a metal, wherein the housing part has at least one opening, through which at least one conductor is fed in a glass or glass ceramic material, and wherein the conductor has at least two sections in the axial direction, a first section made of a first material, e.g. aluminium, and a second section made of a second material, e.g. copper, as well as a transition from the first to the second material, and wherein the transition from the first to the second material is located in the region of the glass or glass ceramic material, said glass or glass ceramic material being adapted to the metal of the housing in such a way that a compression glass-to-metal seal is formed.

Owner:SCHOTT AG

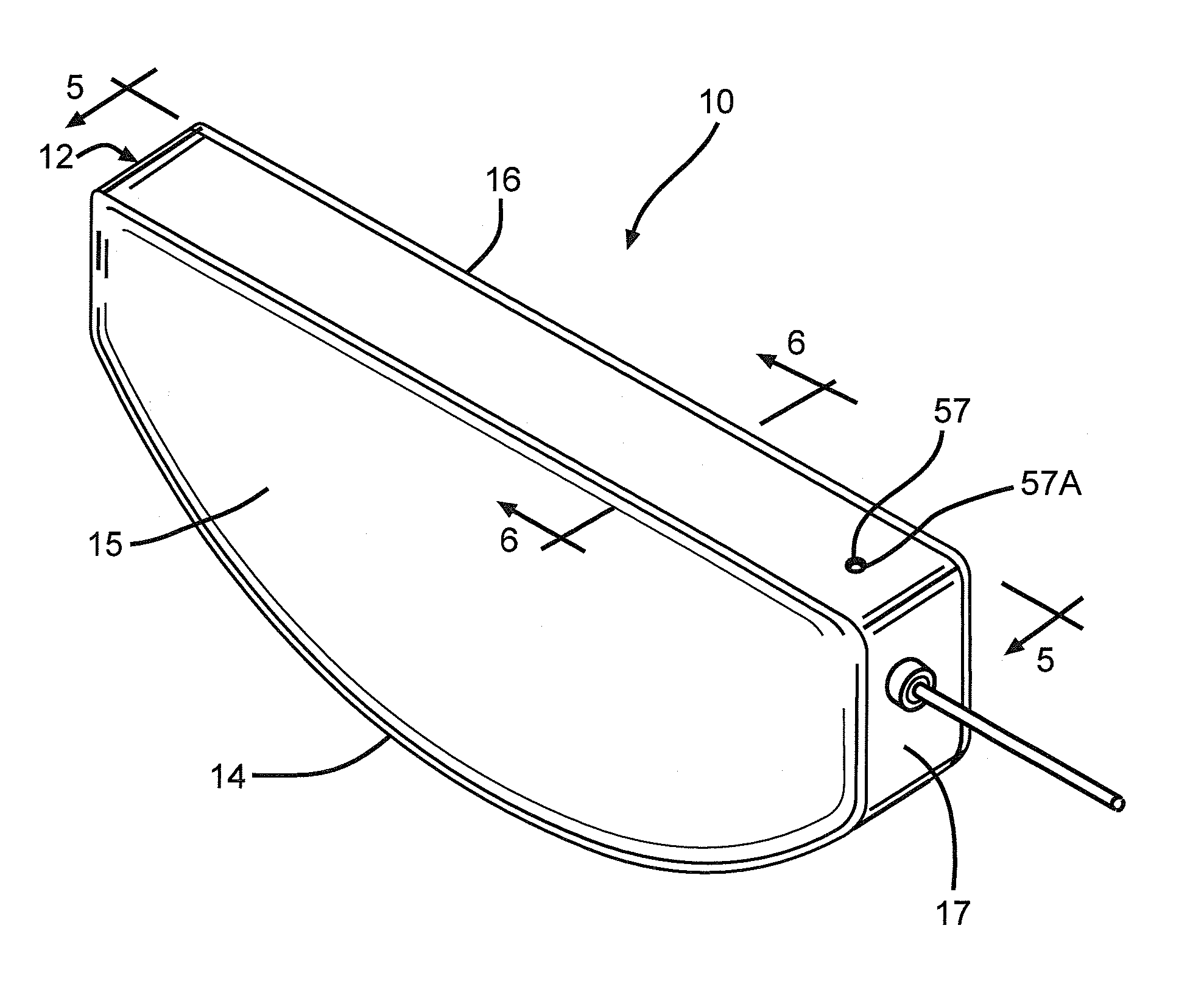

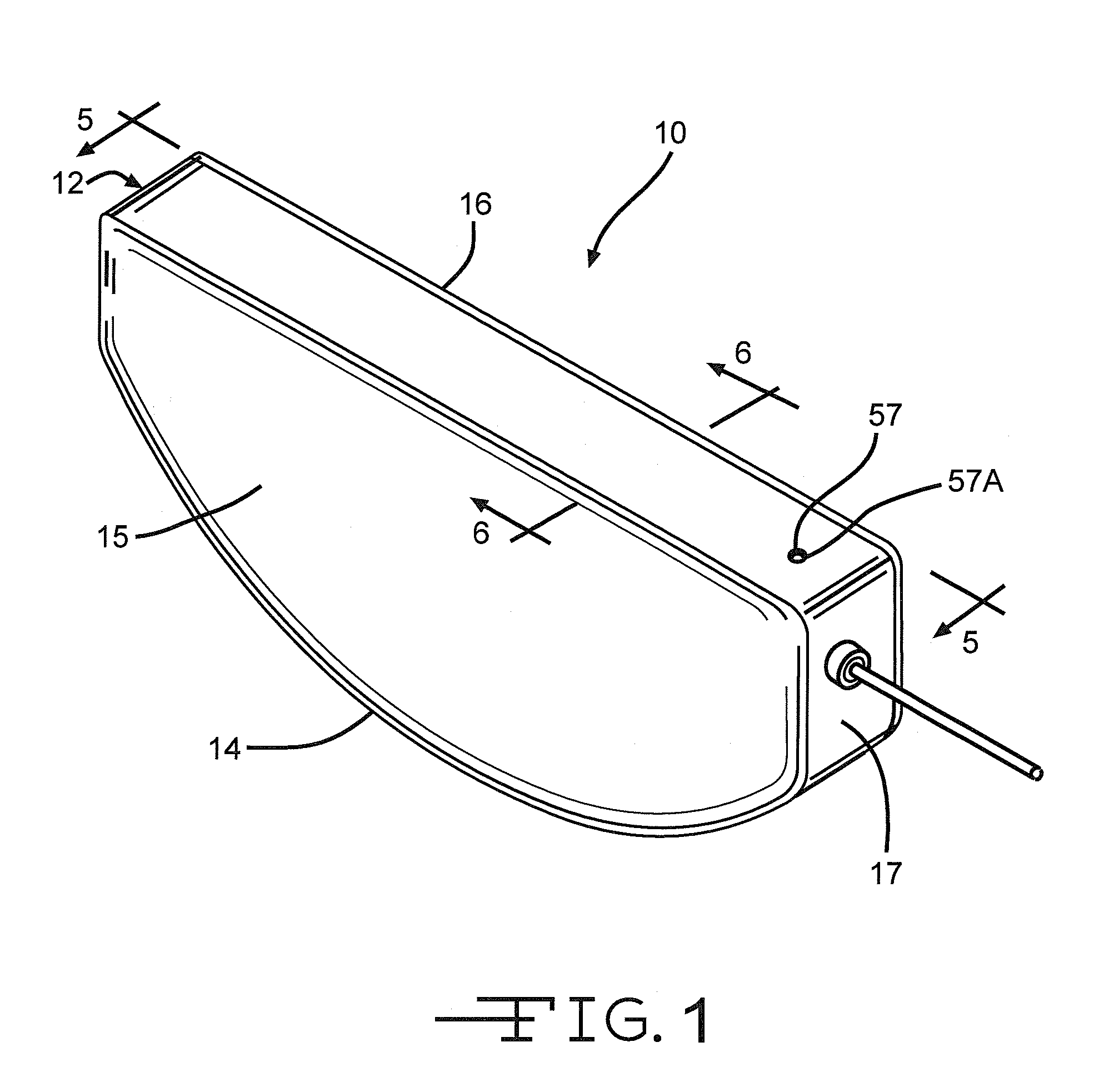

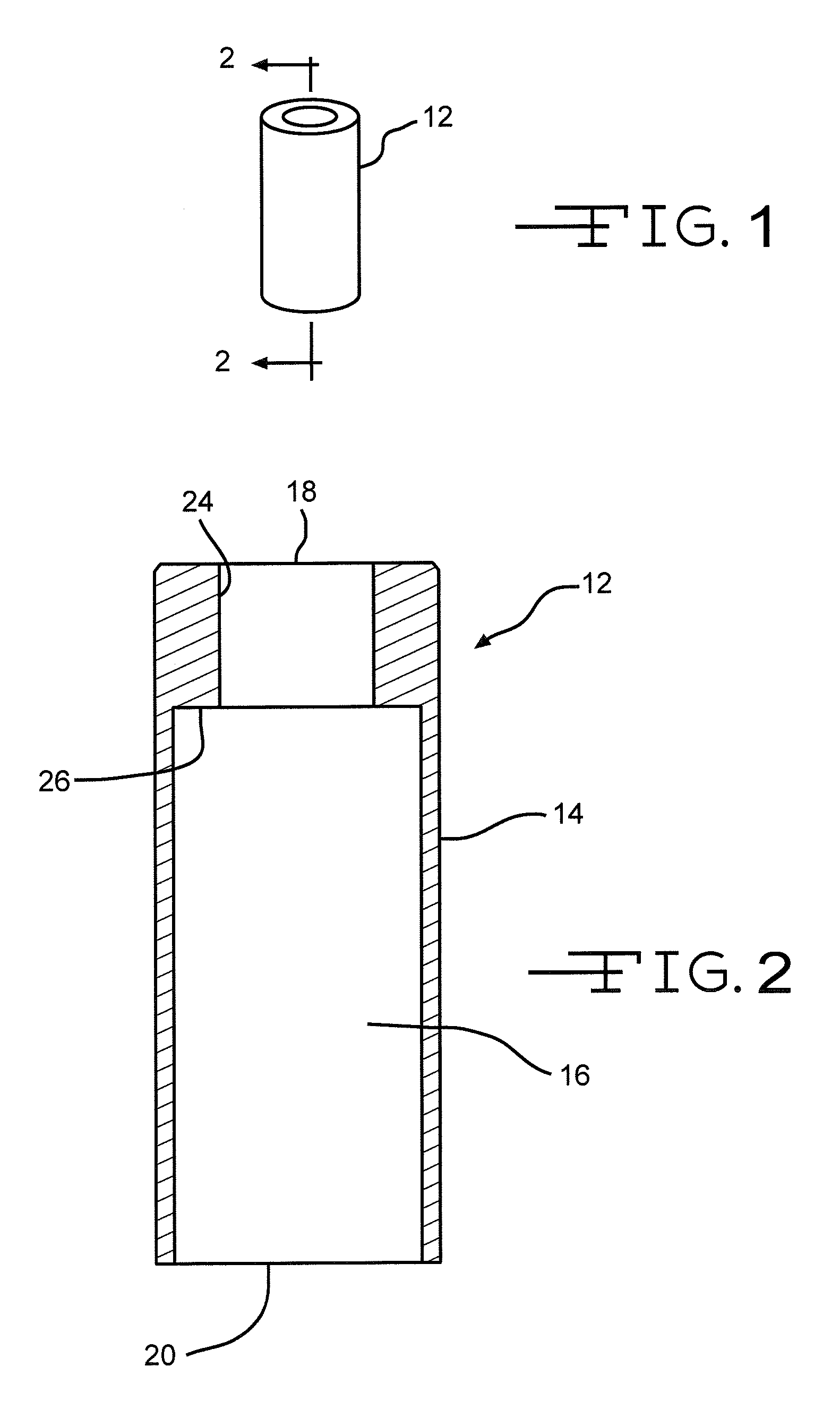

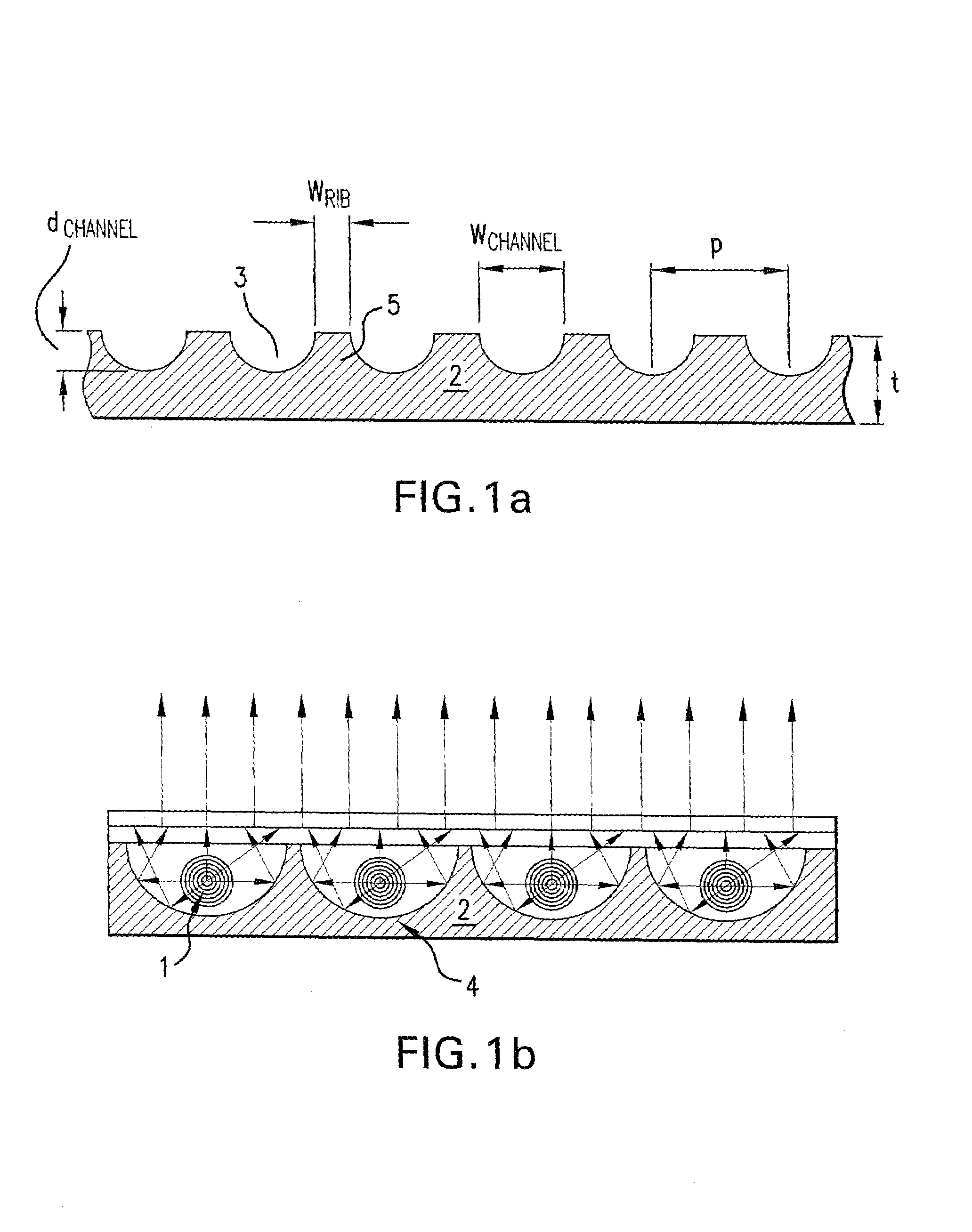

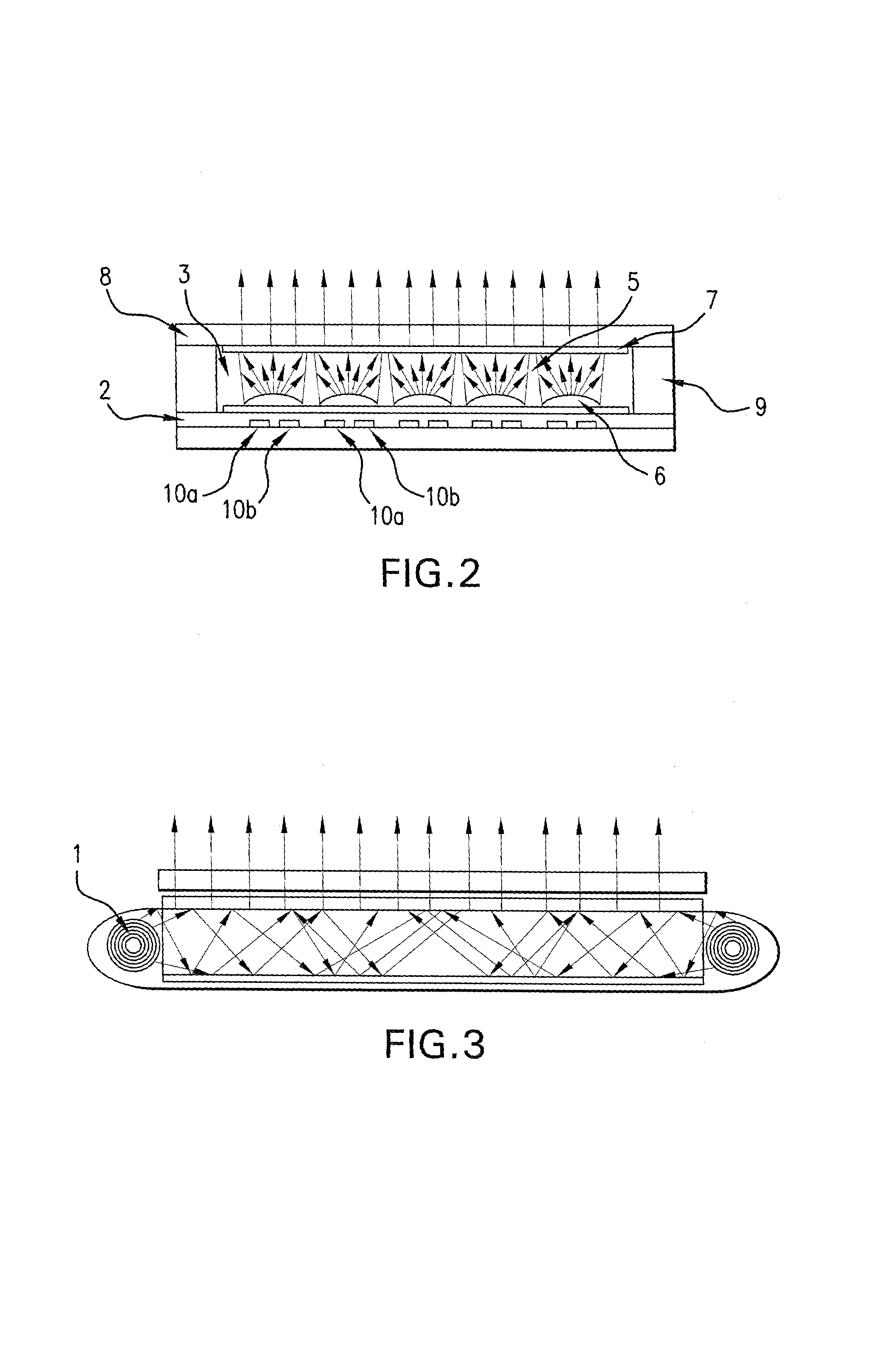

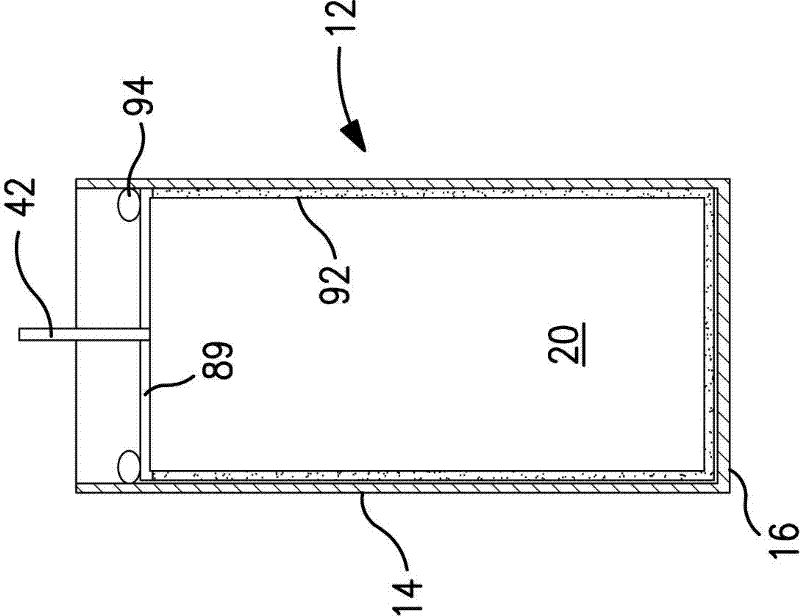

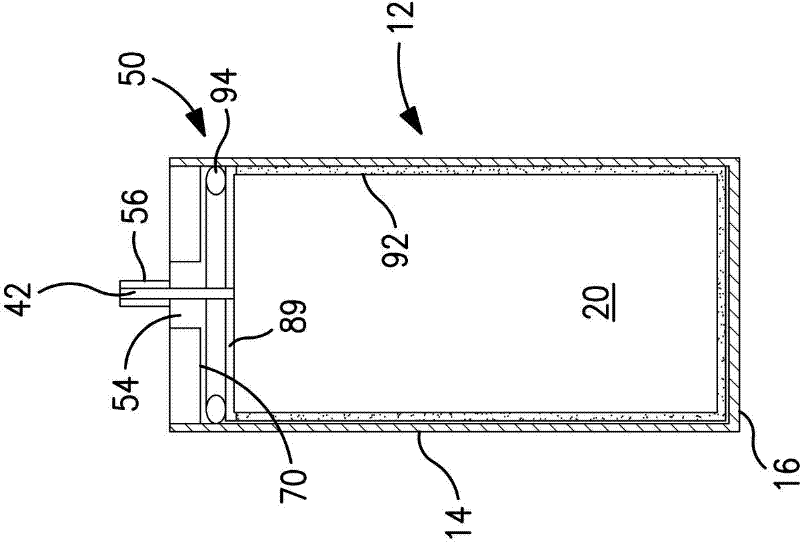

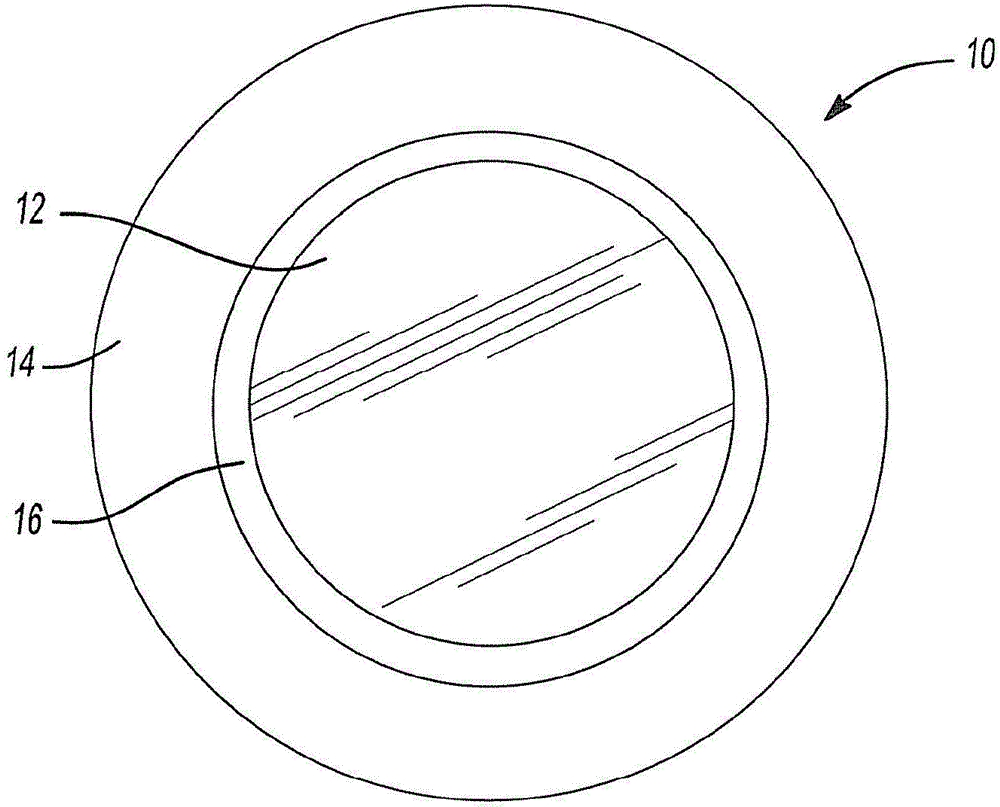

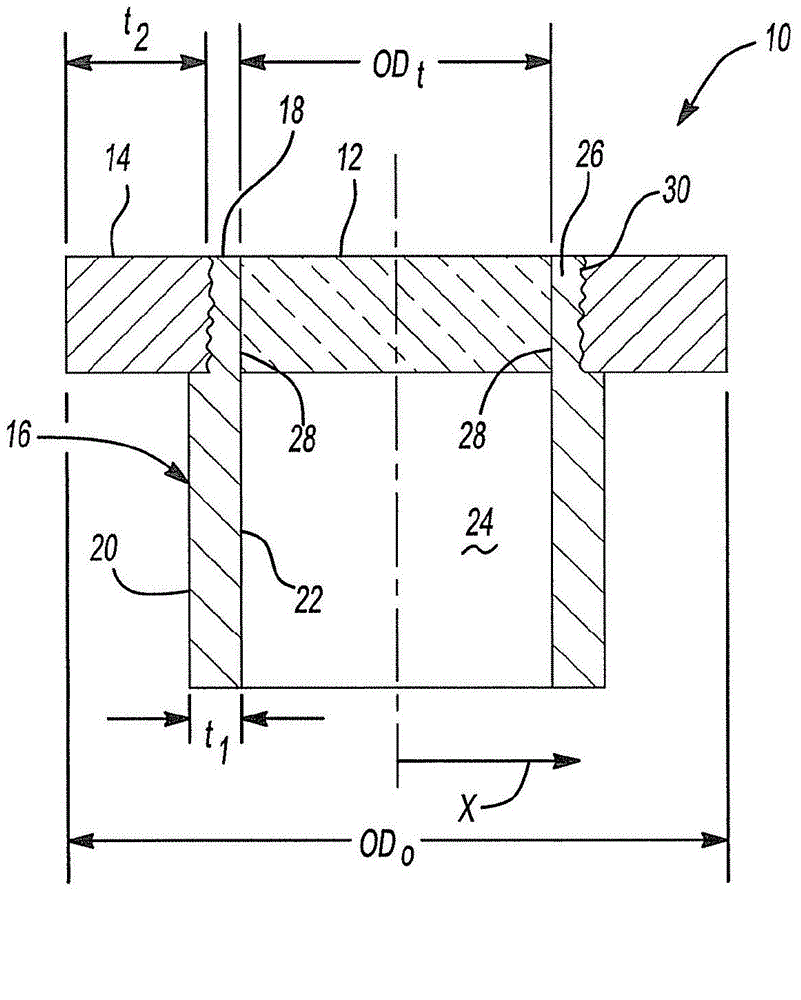

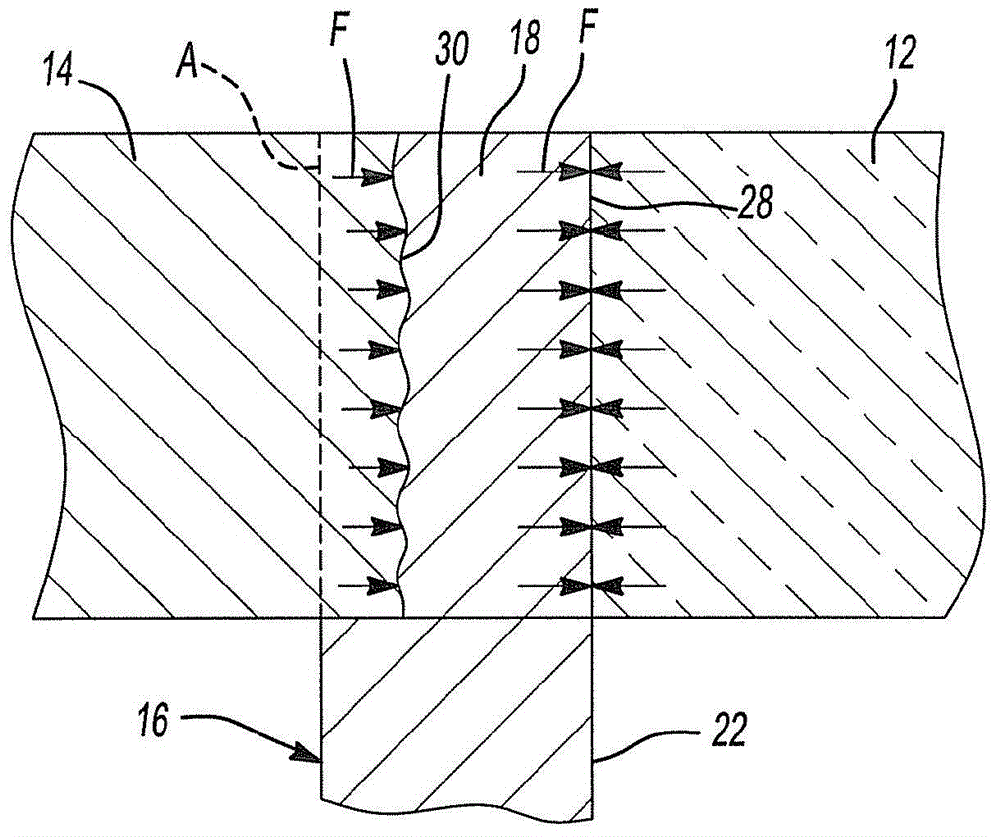

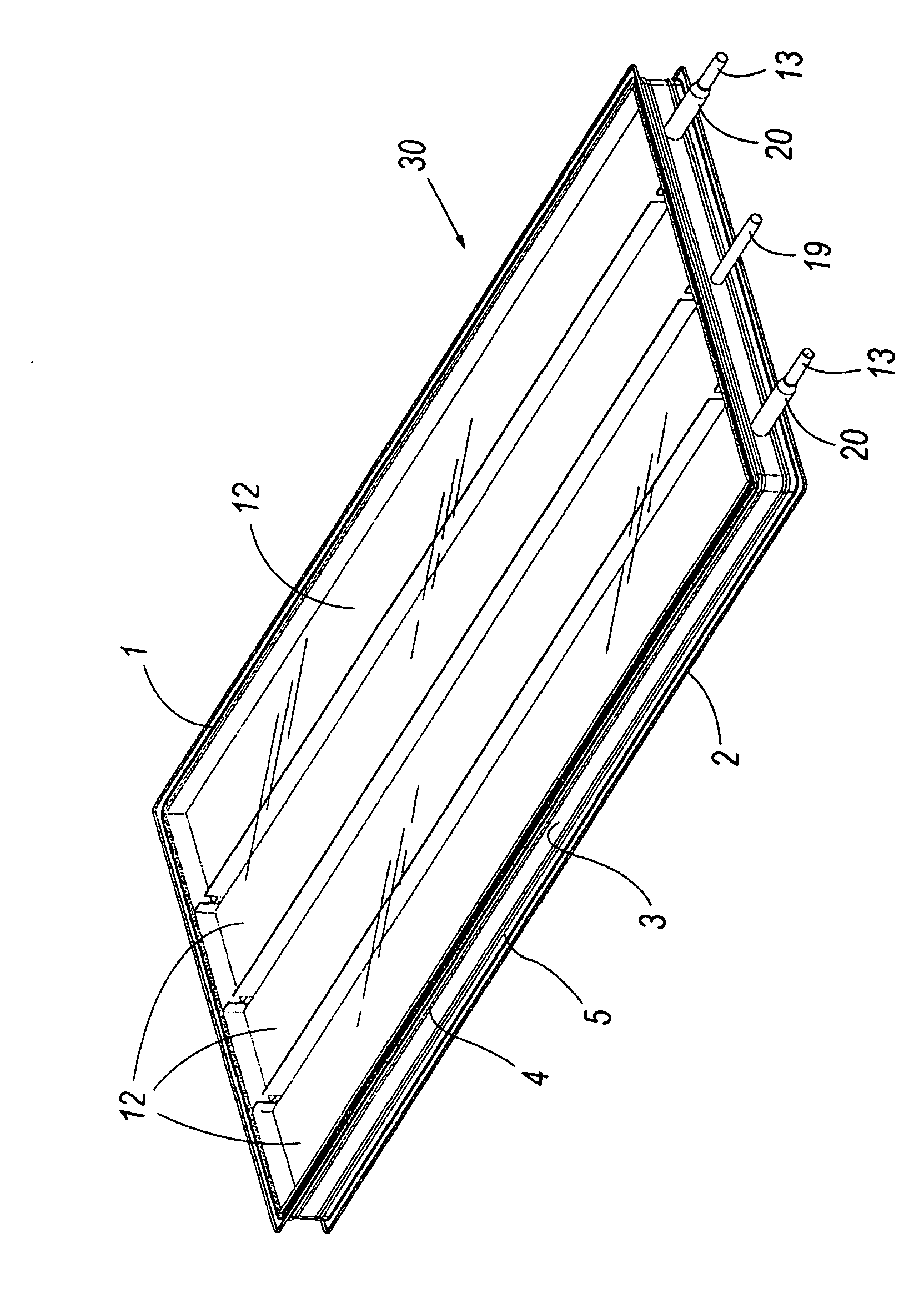

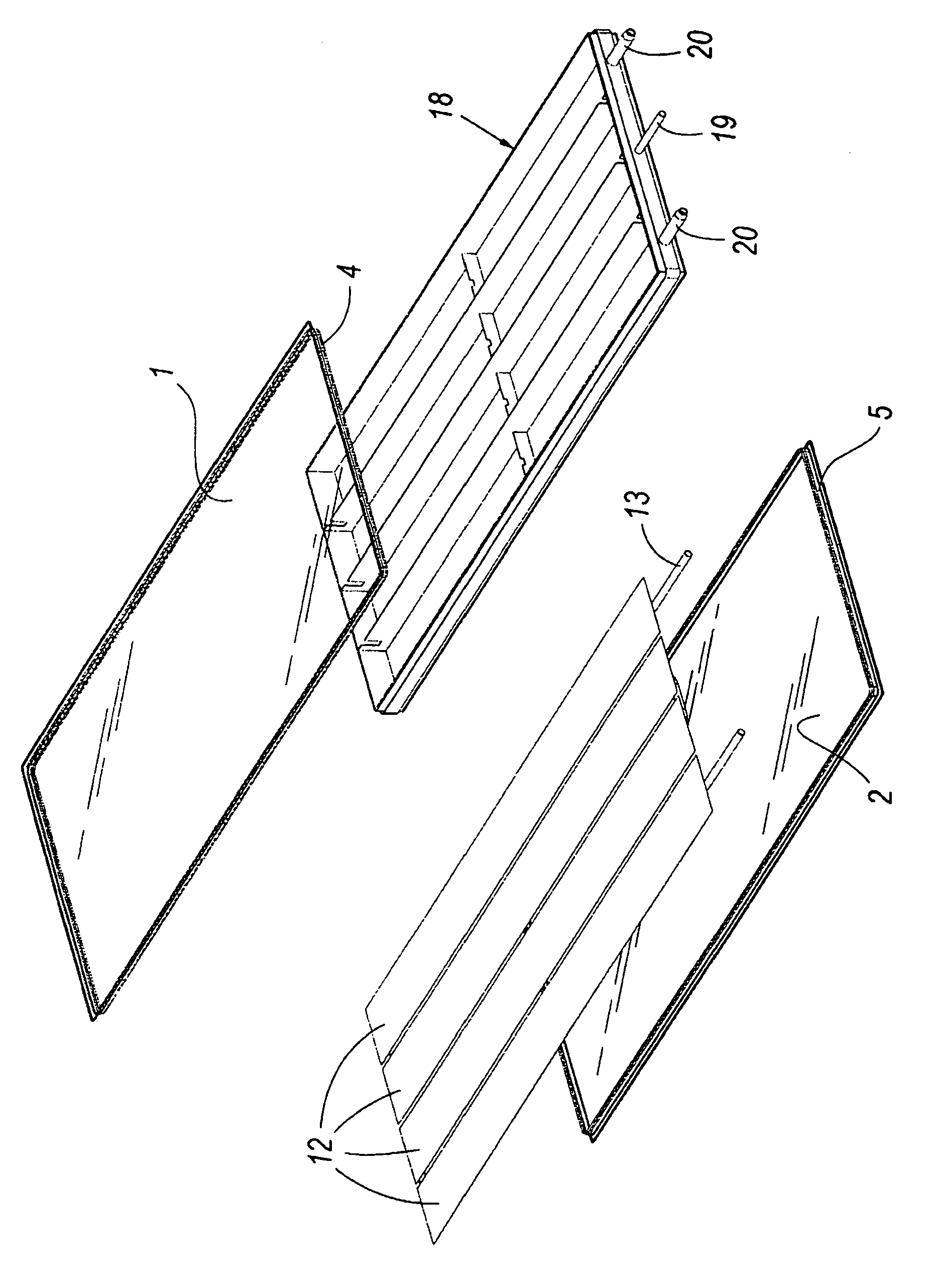

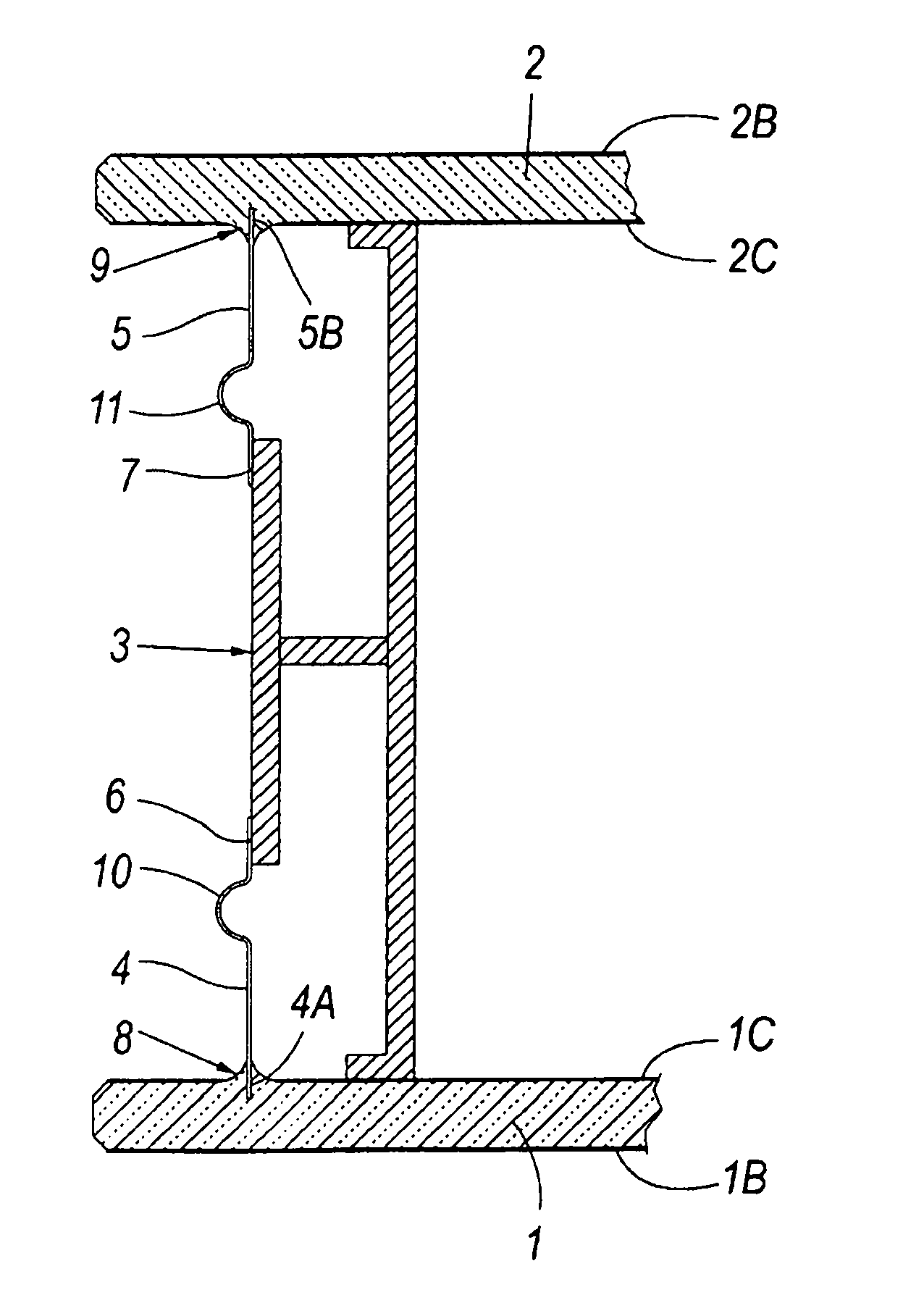

Vacuum solar thermal panel with a vacuum tight glass-metal sealing

A vacuum solar thermal panel comprises a vacuum envelope (30) defining a sealed volume, able to withstand atmospheric pressure when evacuated, at least one heat absorber (12) being disposed inside the vacuum envelope (30), a pipe (13) entering and exiting the envelope (30) and being in contact with the heat absorber (12), said vacuum envelope (30) comprising a first plate (1; 101) made of glass, a peripheral frame (3) disposed substantially at the periphery of the first plate (1; 101), a metallic peripheral belt (4, 5; 104) joining the peripheral frame (3) to the first plate (1; 101), said metallic peripheral belt (4; 104) being joined to the first plate (1; 101) by means of a vacuum tight bulk glass-metal seal (8, 108), comprising glass material (14; 114) and obtained by fusion and subsequent solidification of said glass material (14; 114). The metallic peripheral belt (4; 104) includes at least one elastically deformable portion (10; 110) that prevents the bulk glass-metal seal (8; 108) from getting damaged and is no more vacuum tight when subject to the evacuation process of the envelope and the thermal treatments of the panel and the potential reciprocal displacements of the glass plate (1, 2) and the joined metallic peripheral belt (4, 5;110).

Owner:TVP SOLAR

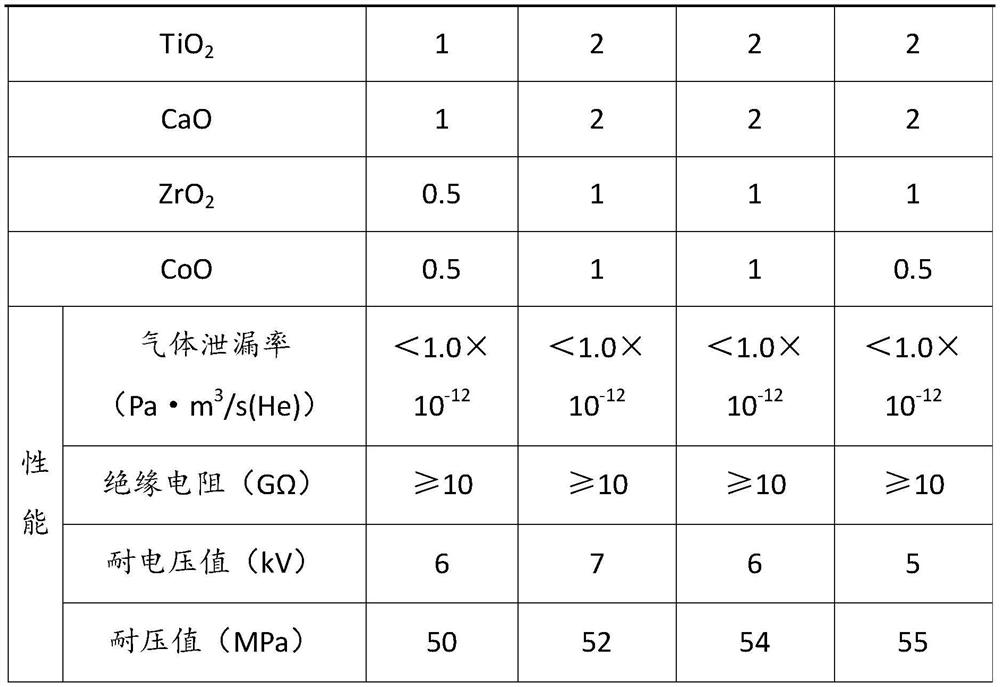

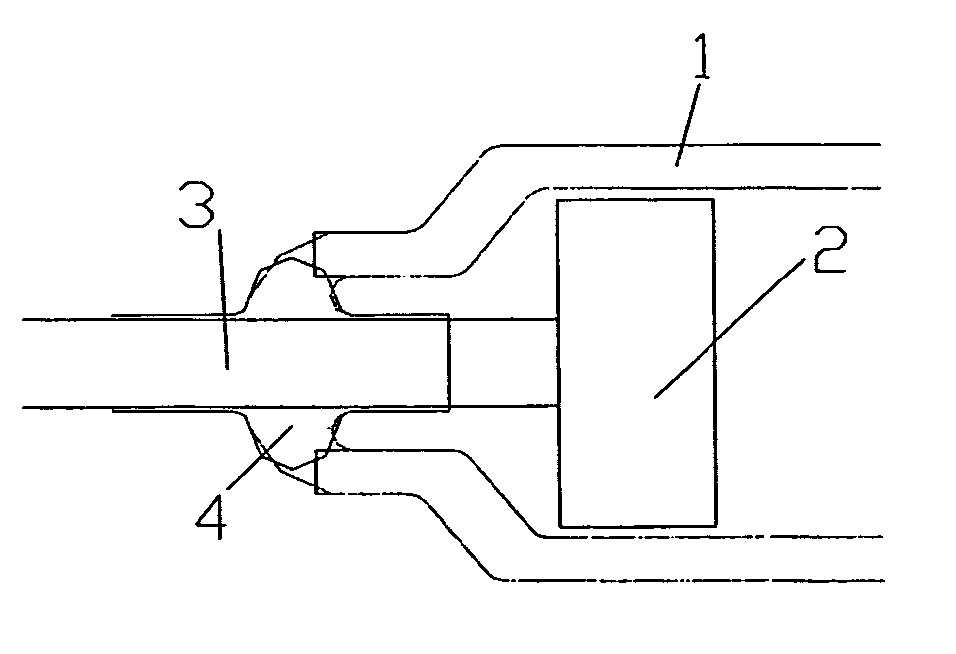

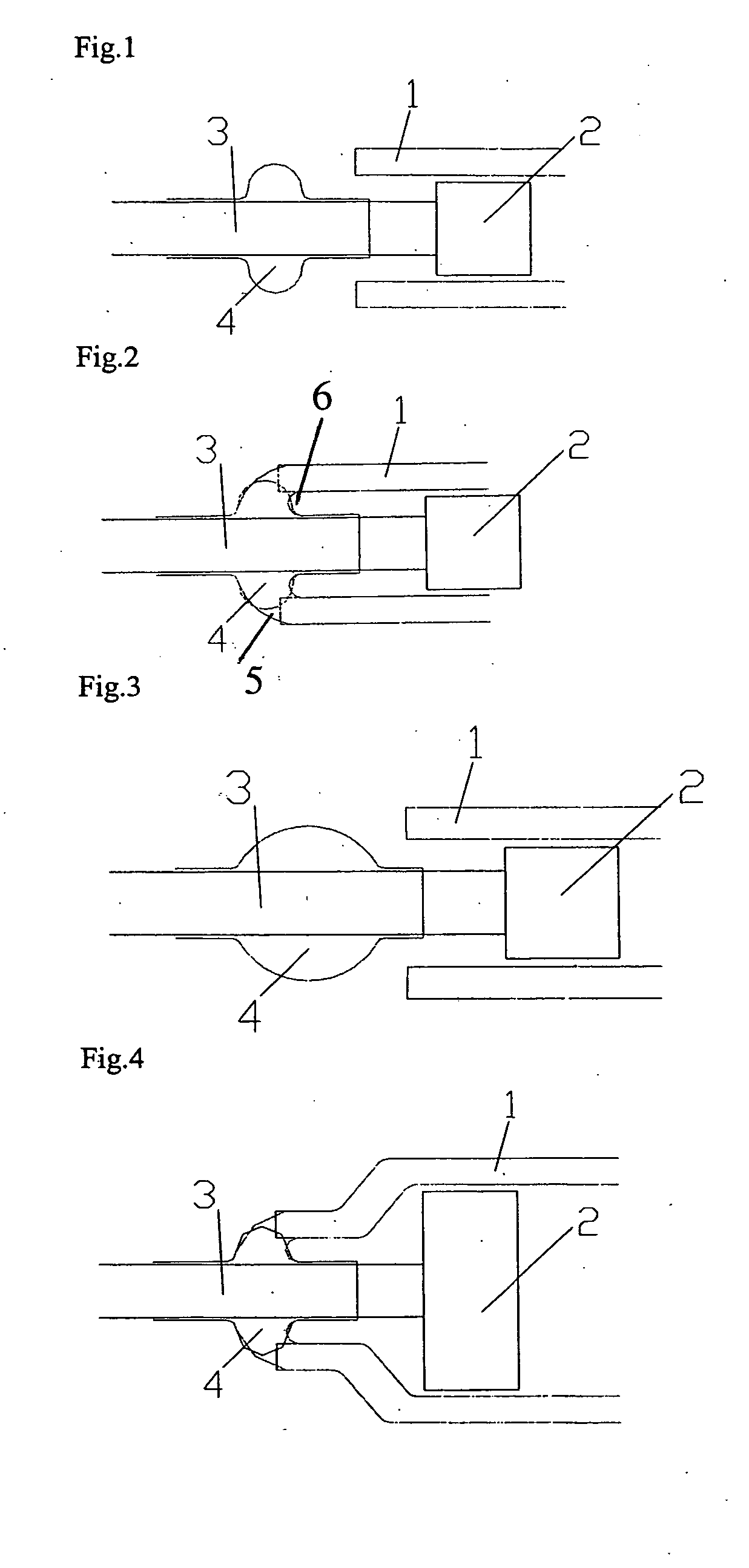

Glass-metal sealing material for pressurized water reactor electrical penetration assembly conductor assembly and preparation method

PendingCN114195397AImprove air tightnessImprove insulation performanceNuclear energy generationContainmentSpray GranulationCompression molding

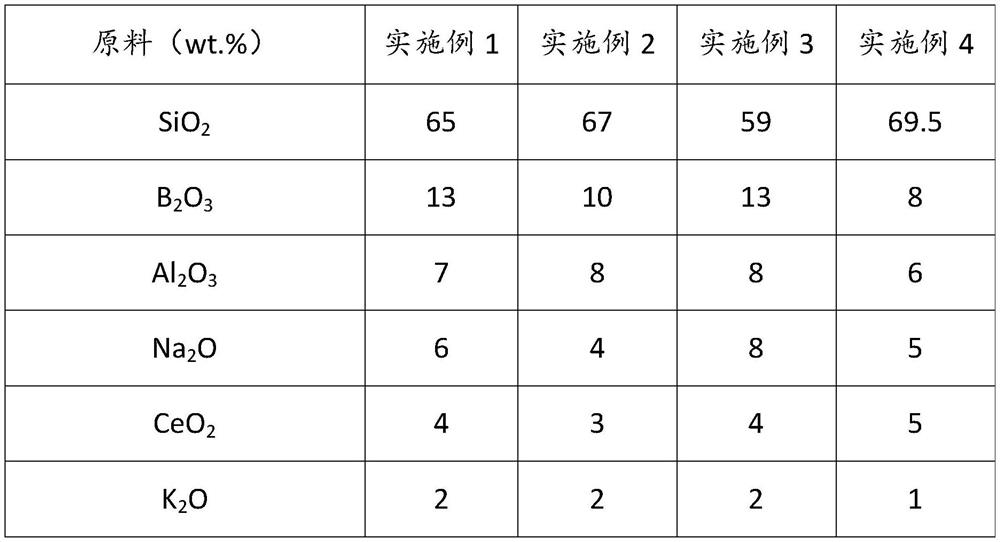

The invention discloses a glass-metal sealing material for a conductor assembly of an electrical penetration assembly of a pressurized water reactor and a preparation method of the glass-metal sealing material. The preparation method comprises the following steps: weighing according to a set glass material ratio, and uniformly mixing the raw materials to obtain a batch; the batch comprises the following components in percentage by weight on the basis of oxides: 50 to 70 percent of SiO2, 8 to 13 percent of B2O3, 4 to 8 percent of Al2O3, 3 to 8 percent of Na2O, 2 to 4 percent of CeO2, 0 to 2 percent of K2O, 0 to 2 percent of TiO2, 0 to 2 percent of CaO, 0 to 1 percent of ZrO2 and 0 to 1 percent of CoO. The preparation method comprises the following steps: melting the batch at 1550-1650 DEG C, quenching to obtain glass slag, carrying out ball milling on the glass slag, and carrying out spray granulation to obtain granulation powder with a certain particle size and sphericity. And preparing the granulated powder into a glass blank with a required shape by compression molding, and placing the glass blank at a certain temperature for glue removal and vitrification to obtain the prefabricated glass bead. And assembling the metal shell, the metal conductor and the prefabricated glass bead, and sealing in an atmosphere furnace to obtain the glass-metal sealed electrical penetration assembly conductor assembly. The conductor assembly prepared by the method has the characteristics of high air tightness, high insulativity, radiation resistance, flame retardance and the like.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH +1

Quartz glass lamp and method for forming a quartz glass lamp

ActiveUS20050258755A1Reduce chanceRaise the biasTube/lamp screens manufactureElectroluminescent light sourcesEngineeringSpherical shaped

A method is provided for formation of a glass to metal seal at one end of a quartz lamp tube, as part of the process of manufacturing a complete lamp tube. The method involves a direct sealing of the tube of quartz glass with a seal material surrounding an electrode or its electrical feed through. The seal material may be in the form of a bead having a generally elliptical or spherical shape.

Owner:HERAEUS NOBLELIGHT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com