Glass-metal sealing material for pressurized water reactor electrical penetration assembly conductor assembly and preparation method

An electrical penetration, metal sealing technology, used in sealing, reducing greenhouse gases, reactors, etc., can solve problems such as loss of sealing and insulation functions, achieve excellent flame retardancy, improve radiation resistance, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

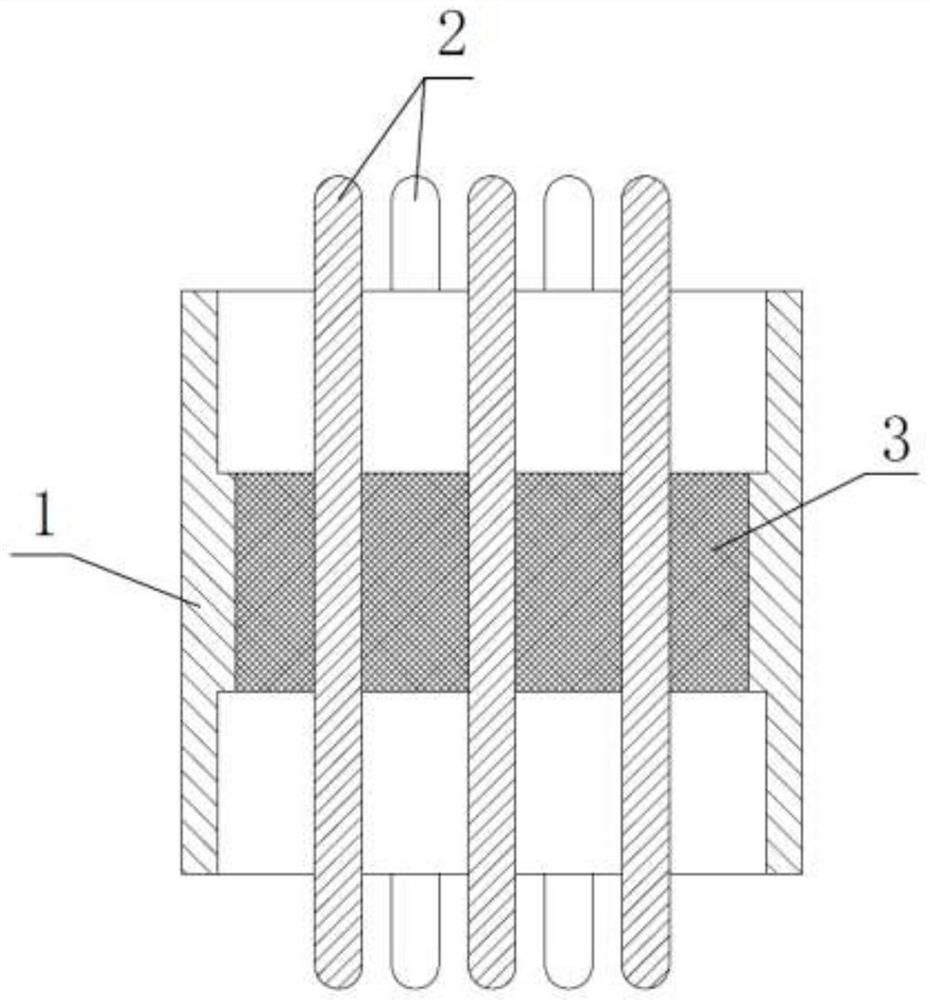

Image

Examples

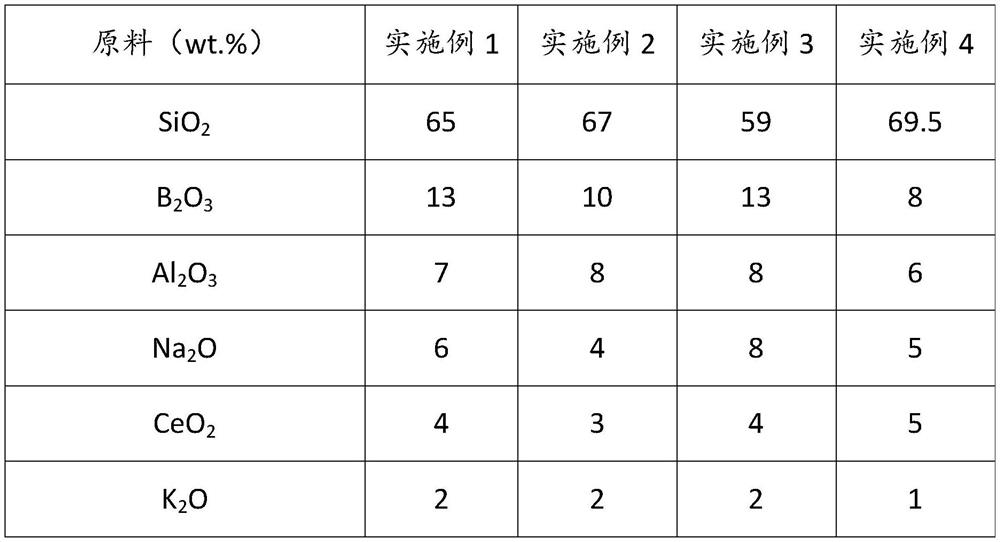

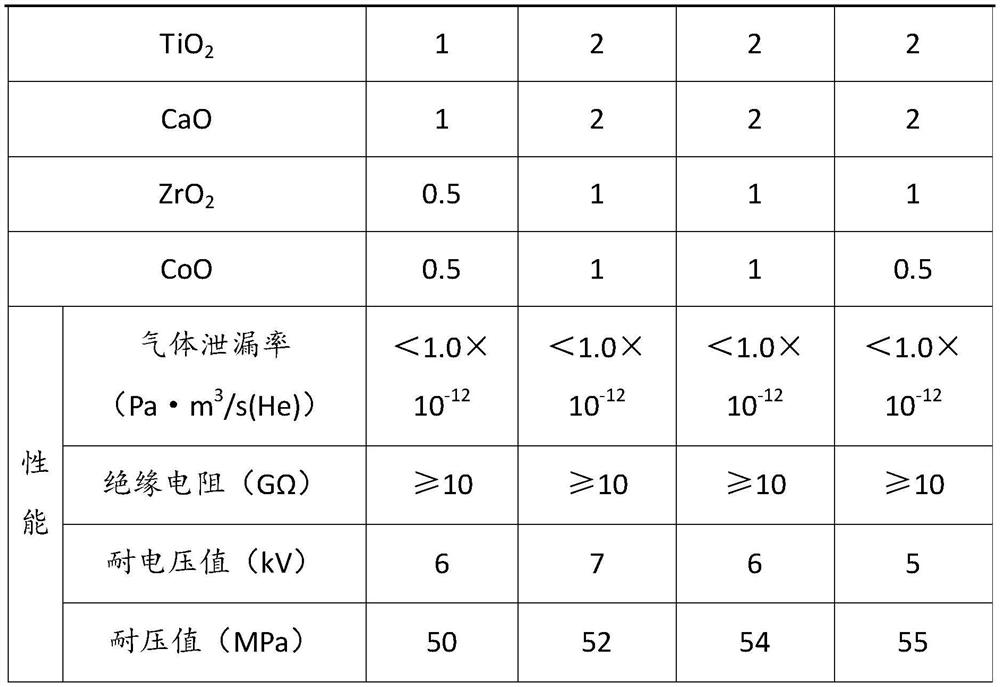

Embodiment 1~4

[0026] 1) Weigh the raw material SiO according to the glass ratio 2 :50~70%, B 2 o 3 :8~13%, Al 2 o 3 :4~8%,Na 2 O:3~8%, CeO 2 :2~4%, K 2 O: 0~2%, TiO 2 :0~2%, CaO:0~2%, ZrO 2 : 0 ~ 1%, CoO: 0 ~ 1%, put the raw materials in a V-shaped mixer and mix for 30 ~ 40 minutes;

[0027] 2) The uniformly mixed raw materials are kept at 1600°C for 100 minutes for high-temperature melting, and glass slag is obtained after water quenching;

[0028] 3) Grinding the glass slag in the planetary ball mill, adding grinding balls according to the material-ball ratio of 1:0.8, and the ball milling time is 120min. The ground glass powder is sieved, and the glass powder under the 150 mesh sieve is taken for subsequent use;

[0029] 4) Disperse the glass powder under the 150-mesh sieve in the liquid phase composed of solvent, dispersant and binder, add grinding balls, and after ball milling for 100min, obtain glass powder slurry, glass powder, solvent, dispersant, binder The mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com