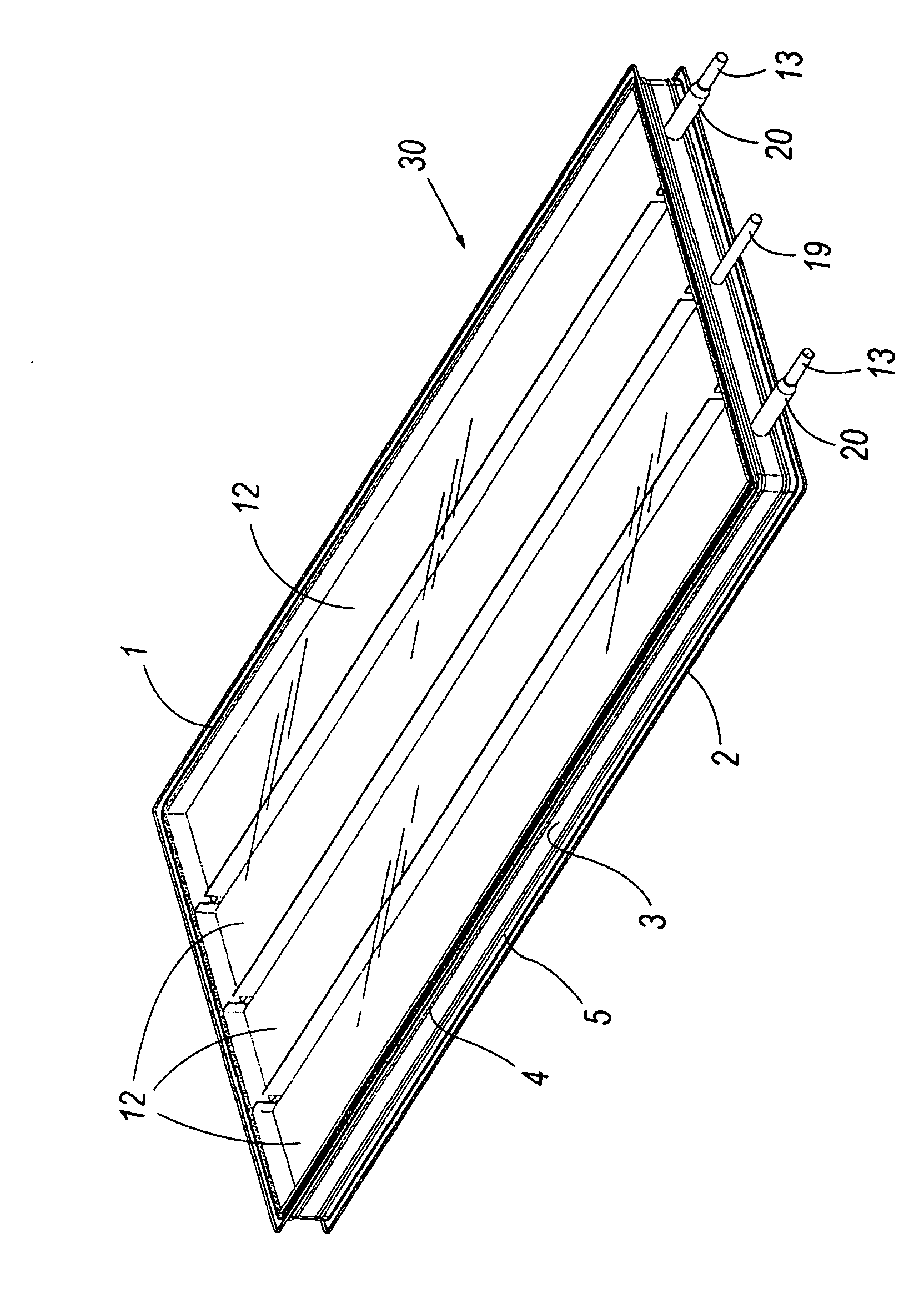

Vacuum solar thermal panel with a vacuum tight glass-metal sealing

A technology of solar thermal panels and airtight glass, applied in solar thermal energy, solar collectors using working fluids, solar thermal power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

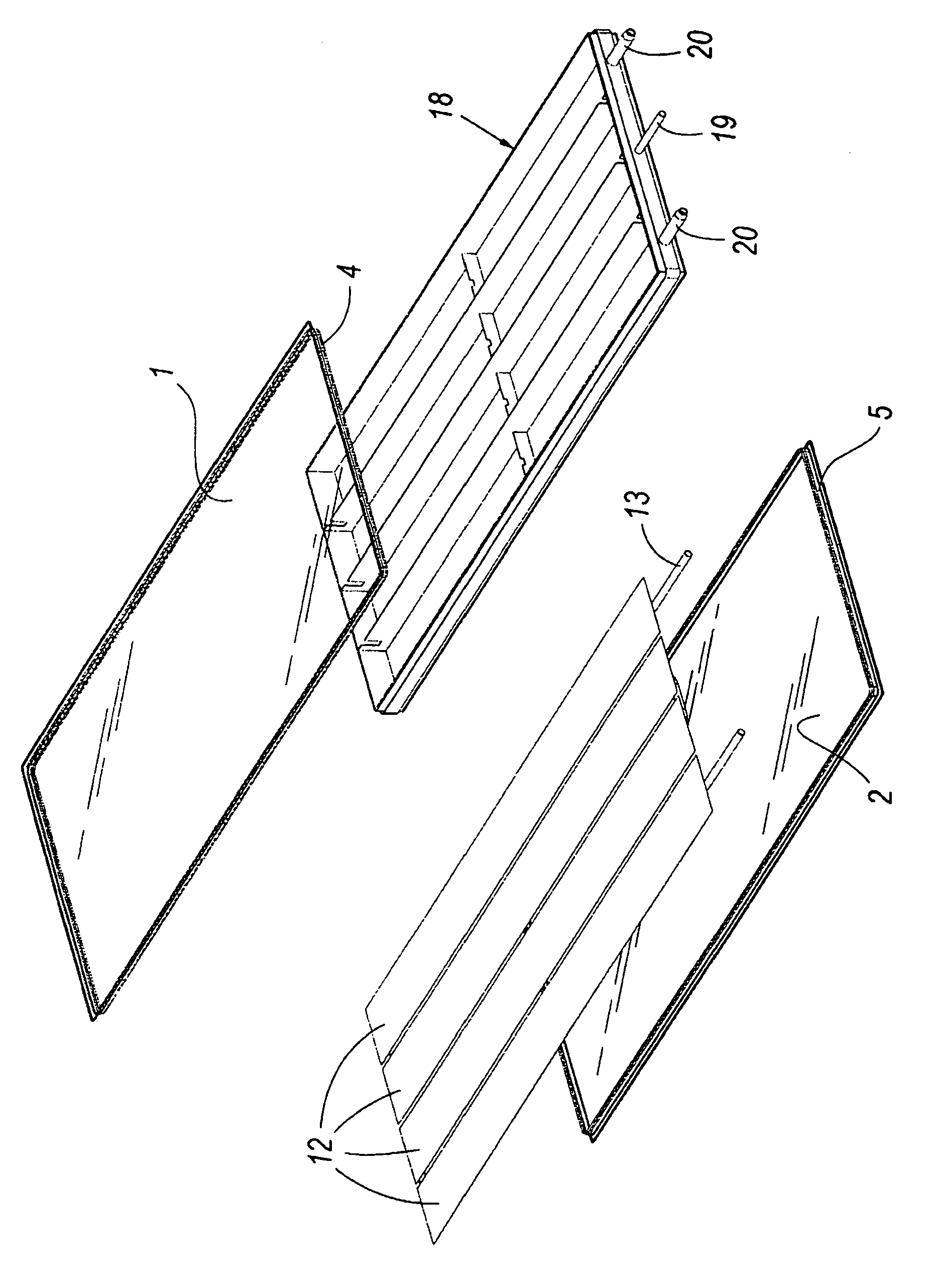

Method used

Image

Examples

no. 2 example

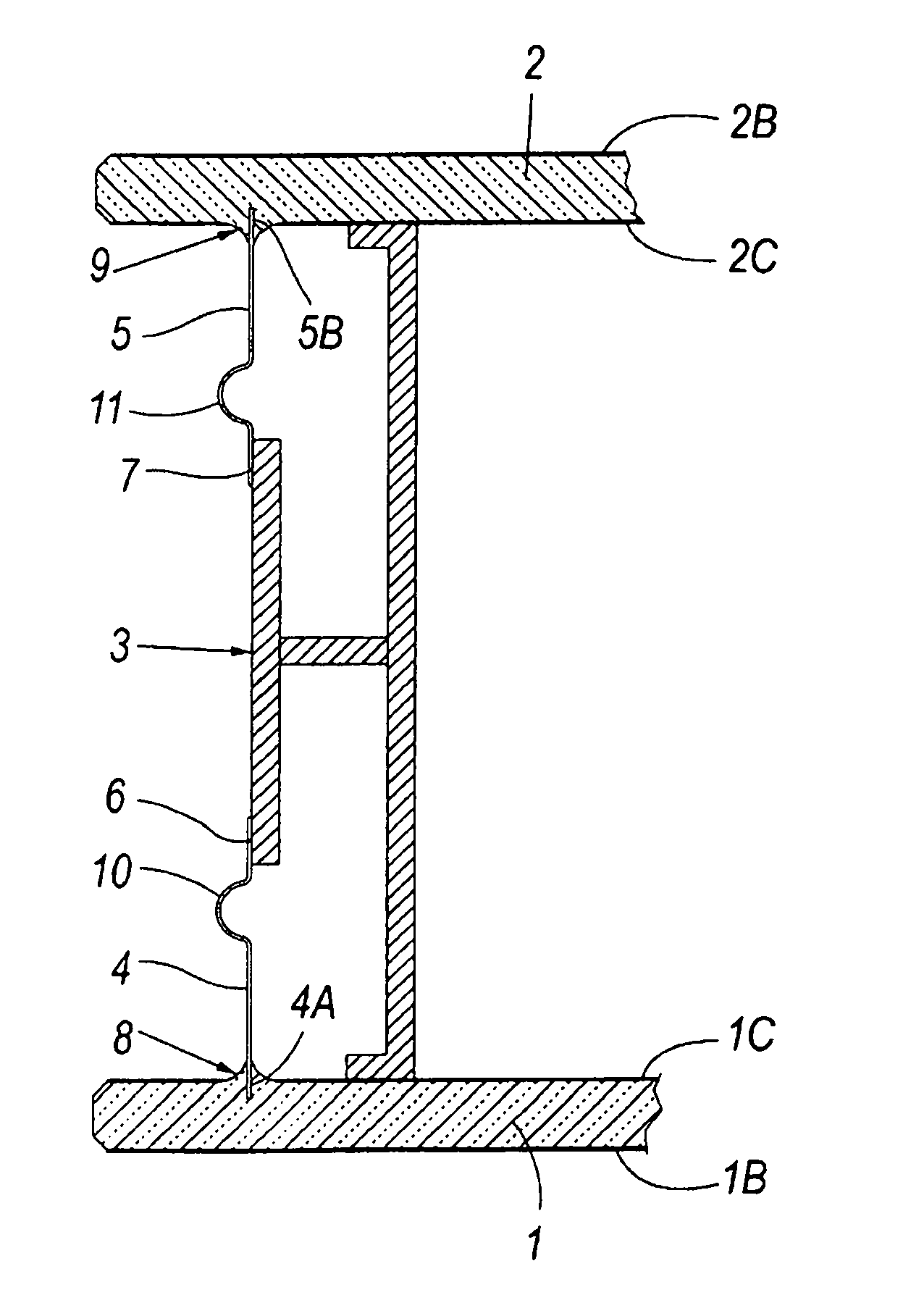

[0036]According to the first or second embodiment of the invention respectively, the vacuum-tight integral glass-metal seal can be of two types:

[0037] a) It can be a matching glass-metal seal 8, so that the edge 16 of the peripheral band 4 is embedded in the glass material 14, due to the glass sheets 1, 2 ( Figure 4 ) obtained by partial melting and subsequent solidification;

[0038] b) It can be a compressed glass-to-metal seal 108 with the edge 116 of the peripheral strip 104 embedded in the glass material 114, since the peripheral strip 104 is in contact with the glass sheet 101 ( Figure 5 ) formed by the melting of connected frit glass materials.

[0039] In both embodiments, the glass material 14 , 114 is adhered directly to the metal perimeter band 4 , 104 . In the first embodiment the glass material 14 is part of the first plate 1 which is always made of glass, whereas in the second embodiment the glass material 114 is formed at the edge of the metallic peripher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com