Hermetically sealed wet electrolytic capacitor

一种电解电容器、湿式的技术,应用在电解电容器、液体电解电容器、电容器等方向,能够解决电容器DC漏电流高、电解质泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0073] According to the present invention, a wet electrolytic capacitor is manufactured. First, follow the Figure 7-8 The manner shown forms a liquid seal. More specifically, a glass-to-metal seal 300a is threaded onto the wire 320 through a tantalum tube 322 topped against a bead 380 at the end of the wire. Then, a first perform 350a comprising a PFA layer 360 and a PTFE layer 362 (obtained from Electrolock Corporation) is placed on the wire 320 and on the seal 300, the PFA layer 360 facing the seal 300a. Another preform 350b is also placed on the line 320 so that the PTFA layers of each preform fit together. A second glass-metal seal 300b is threaded onto line 320, which is inverted relative to the first glass-metal seal. Additional sealing pairs are placed in the same manner until a manageable stack is obtained. A weight 370 (25-50 g) is attached to the wire 320 and the whole assembly is then placed into the oven using the fork support 373 on the bottom of the stack. ...

example 2

[0076] According to the present invention, a wet electrolytic capacitor is formed. First follow Figure 9-10 The manner shown forms a liquid seal. More specifically, a glass-to-metal seal 400 is threaded through a tantalum tube to a line. A preform 450 comprising a PFA layer 460 , a PTFE layer 462 and a PFA layer 464 (obtained from Electrolock Corporation) is then placed on the wire 420 and on the seal 400 with the PFA layer 460 facing the seal 400 . A weight 470 (10 g) was attached to the wire 420 and the entire assembly was placed in the oven. The oven temperature was raised to 330°C and maintained for 15-30 minutes, then the oven was turned off. When cooled down, the stack is removed and disassembled so that a single seal is easily accessible and contains the fluorocarbon disk laminated to the tantalum-glass-metal part. The resulting seal is then assembled as described in Example 1 with a tantalum anode 480, metal housing (not shown) and electrolyte.

example 3

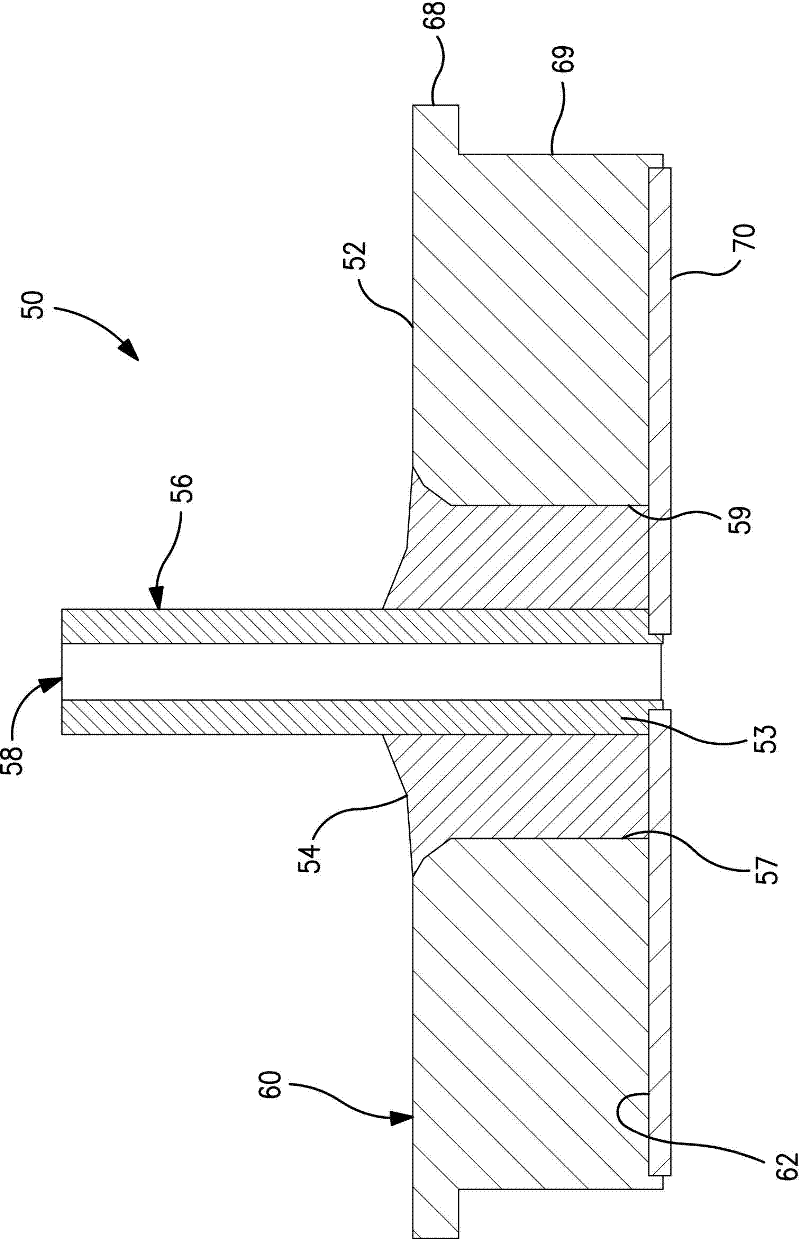

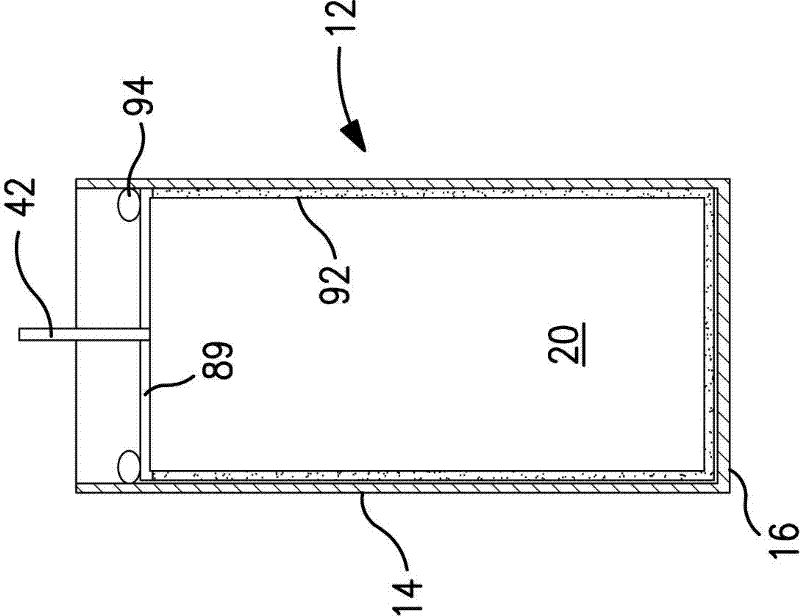

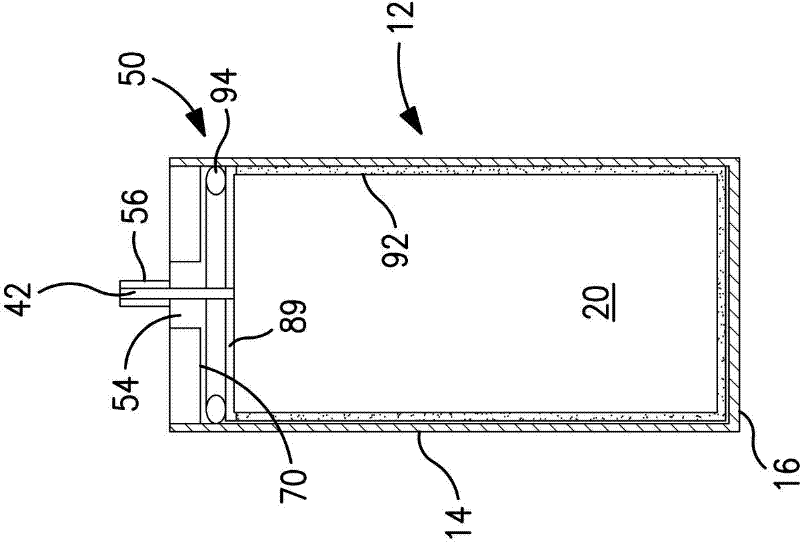

[0078] According to the present invention, a wet electrolytic capacitor is formed. Such as Figure 11 As shown, a single PFA layer disc 550 is threaded onto a formed anode riser line 542 which is then inserted into tube 556 . Then, the seal 500, disc 550 and anode 580 were placed upside down in an oven at 333° C. such that the weight of the anode pressed against the PFA disc. The assembly was held at this temperature for half an hour and then cooled. The assembly is then placed into a metal housing 512 into which a certain amount of electrolyte has been added and a Teflon holder 555 has been placed. Press the seal into the jar and weld the circumference. The base tube is laser sealed and the leads are attached in a manner known in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com