Glass metal sealing device of intermediate temperature solar heat pipe receivers

A technology of solar heat pipe and glass metal, which is applied in the field of sealing devices, can solve the problems of many solder joints, sealing and thermal expansion hindering wide application, increasing unreliability, etc., and achieves the effects of prolonging service life, cheap sealing structure, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

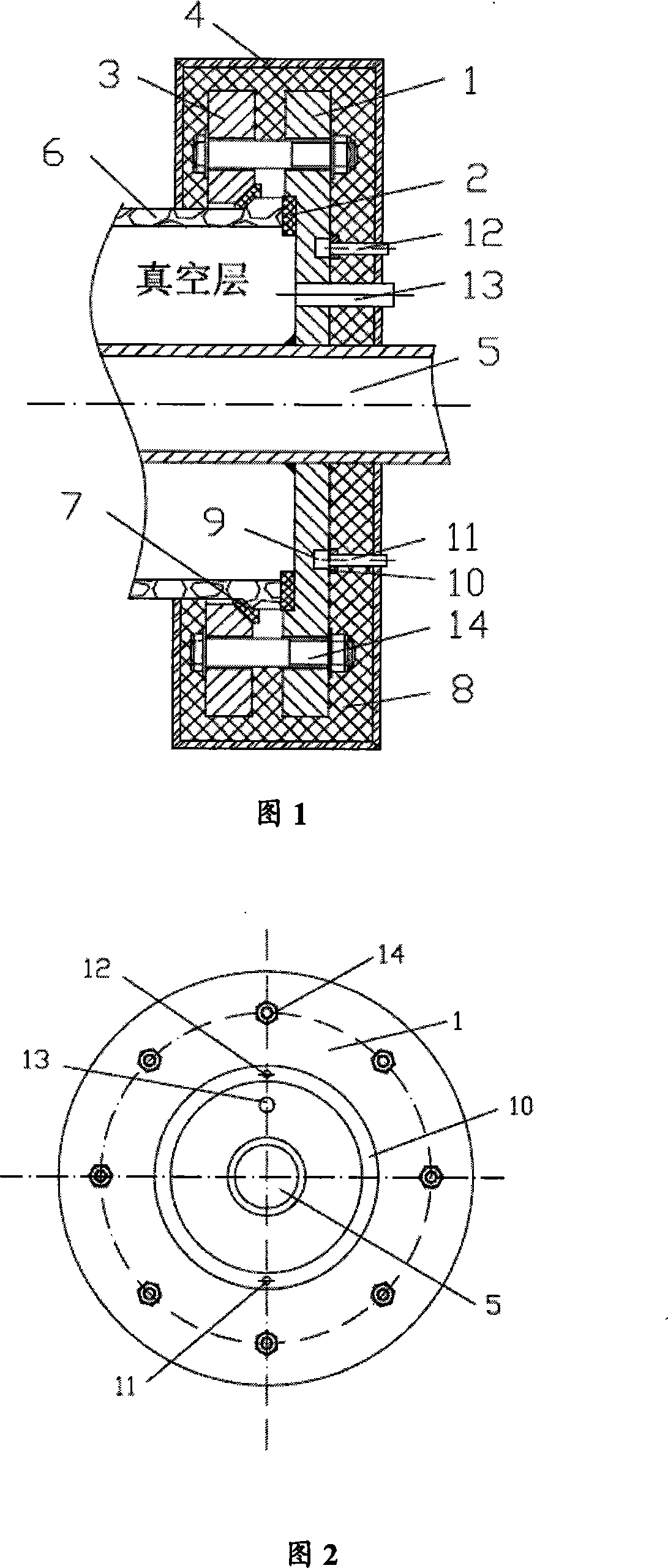

[0015] The specific structure of the glass-metal sealing device used in the medium-temperature solar heat pipe receiver of this embodiment is shown in Fig. 1 and Fig. 2 , including a metal cover 1 , a sealing ring 2 , a metal flange 3 and a shield 4 . The heat pipe 5 passes through the center of the metal cover 1 and is sealed and welded with the metal cover 1. The glass sleeve 6 and the metal cover 1 are sealed by the sealing ring 2. Bolts are respectively opened on the metal cover 1 and the metal flange 2. hole, the metal cover plate 1 and the metal flange plate 2 are connected by bolts 14, and after the bolts 14 are tightened, the metal cover plate 1, the sealing ring 2, the flanging of the glass casing 6, the anti-pressure gasket 7 and the metal flange The disc 3 is pressed tightly so that a vacuum layer is formed between the metal cover plate 1 , the glass casing 6 , the sealing ring 2 and the heat pipe 5 . A pressure-proof gasket 7 is installed between the metal flange 2...

Embodiment 2

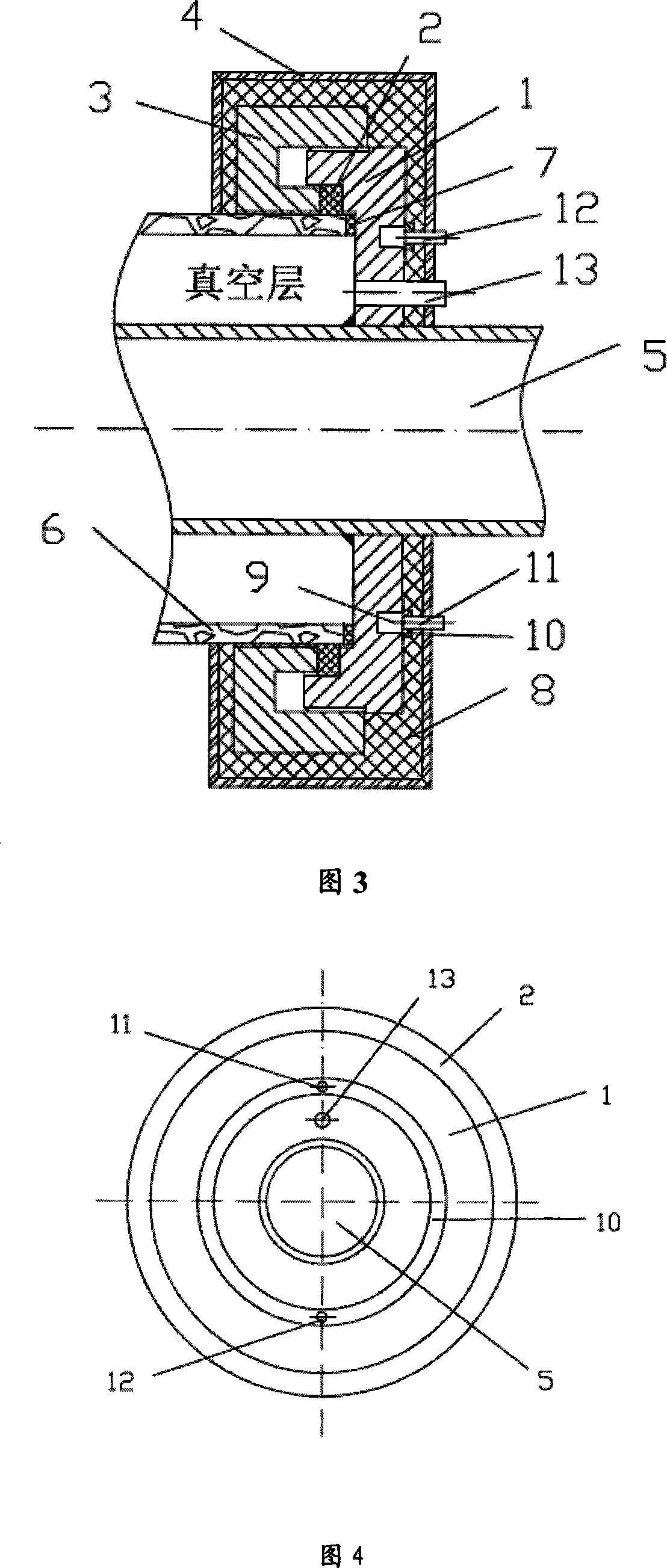

[0018] The specific structure of the glass-metal sealing device used in the medium-temperature solar heat pipe receiver of this embodiment is shown in Fig. 3 and Fig. 4, including a metal cover plate 1, a sealing ring 2, a metal flange 3, and a shielding cover 4. The heat pipe 5 passes through the center of the metal cover 1 and is sealed and welded with the metal cover 1. The glass sleeve 6 and the metal cover 1 are sealed by a sealing ring 2. Threads are respectively processed on the metal cover 1 and the metal flange 2. , through threaded connection, assembled screw thread, the metal cover plate 1, sealing ring 2, glass casing 6 and metal flange 3 are pressed tightly, so that the metal cover plate 1, glass casing 6, sealing ring 2, heat pipe 5 to form a vacuum layer, the contact surface between the metal cover plate 1 and the sealing ring 2 and the contact surface between the outer surface of the tube wall of the glass sleeve 6 and the sealing ring 2 are the sealing surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com