Foam gun

A technology of foaming gun and gun body, which is applied in the direction of spraying device, spraying device, liquid spraying device, etc. It can solve the problems such as the degree of sealing is not up to standard or there is a slight leak, the cost is increased, and the liquid nozzle is worn out. Achieve the effects of preventing leakage of foam filler or gas phenomenon, improving foaming quantity and quality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

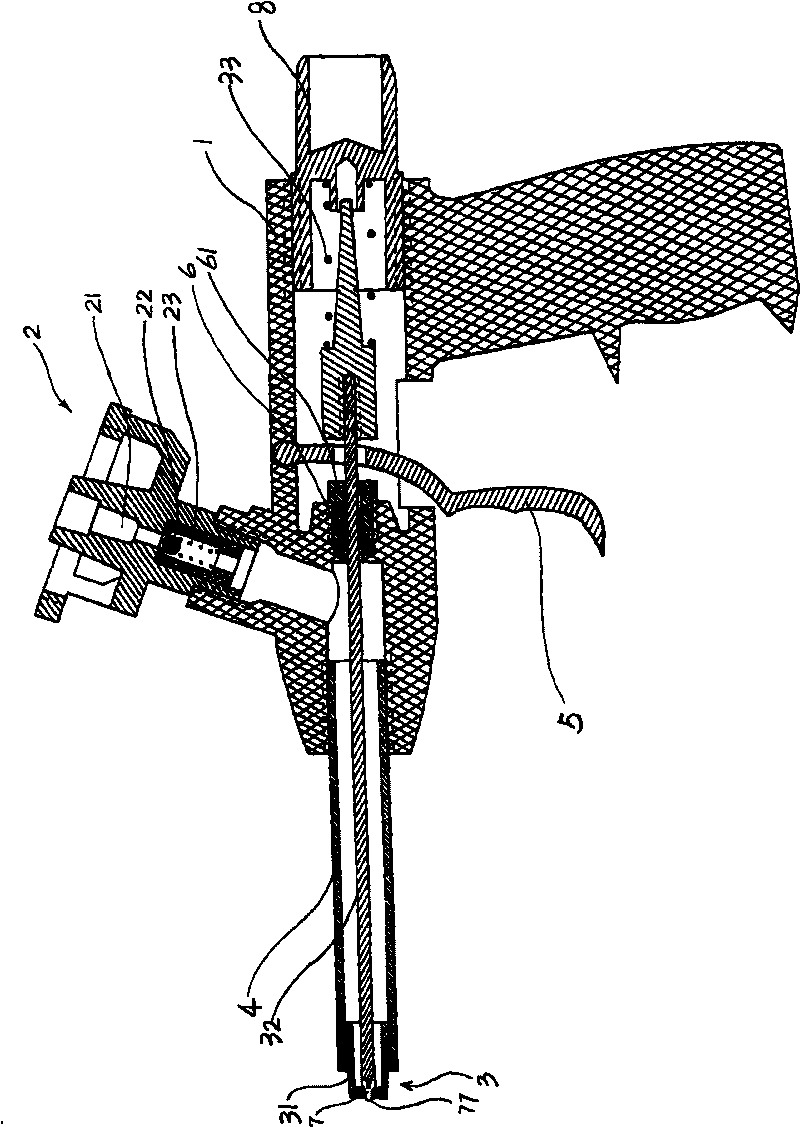

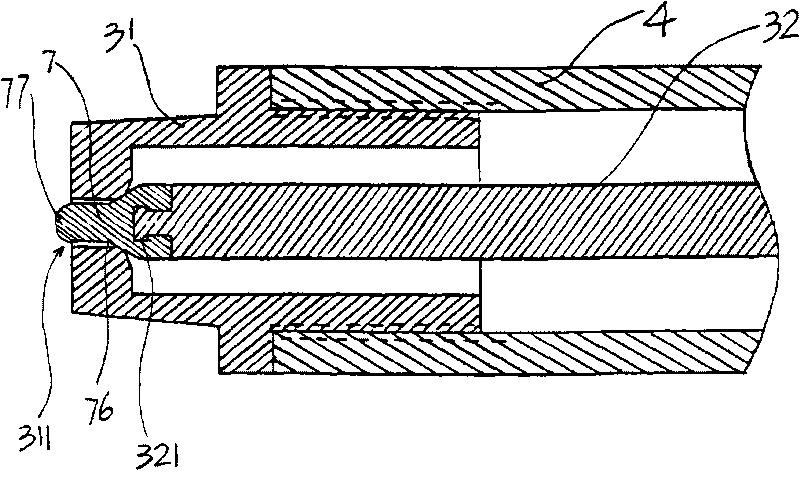

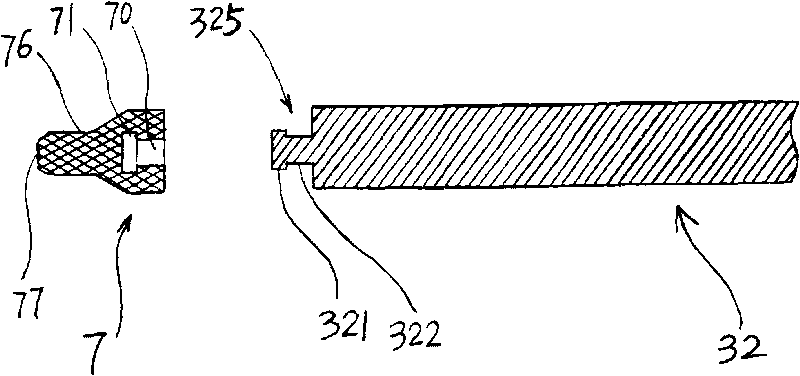

[0045] A foaming gun of the present invention, referring to all accompanying drawings, it includes a gun body 1, a liquid inlet valve 2, a liquid outlet valve 3, a liquid outlet channel 4 and a switch device 5, and the liquid outlet valve 3 includes an outlet valve with an outlet 311 Liquid nozzle 31, spool 32 and back-moving spring 33, switch device 5 can make liquid outlet valve 3 open or close, for example, spool 32 at least partially stretches out the internal channel of foaming gun, makes switch device 5 can directly or indirectly Acting on the spool 32 to make the spool 32 move, the head of the spool 32 is provided with a metal seal 7, and the head of the spool 32 is integrated with the metal seal 7 Structure, the metal seal 7 made integral with the valve core 32 is sealed with the liquid outlet nozzle 31, the valve core 32 is made of alloy materials including stainless steel or stainless iron or copper material, which has high strength and is not easy to oxidize and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com