Electrostatic anti-scaling full glass vacuum photovoltaic generating heat collection tube with fluid director

A photovoltaic power generation, all-glass technology, applied in the field of solar energy applications, can solve the problems of blocking scattered light from entering, serious heat dissipation, poor thermal insulation performance, etc., to achieve the effects of reducing heat radiation, high heat absorption efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

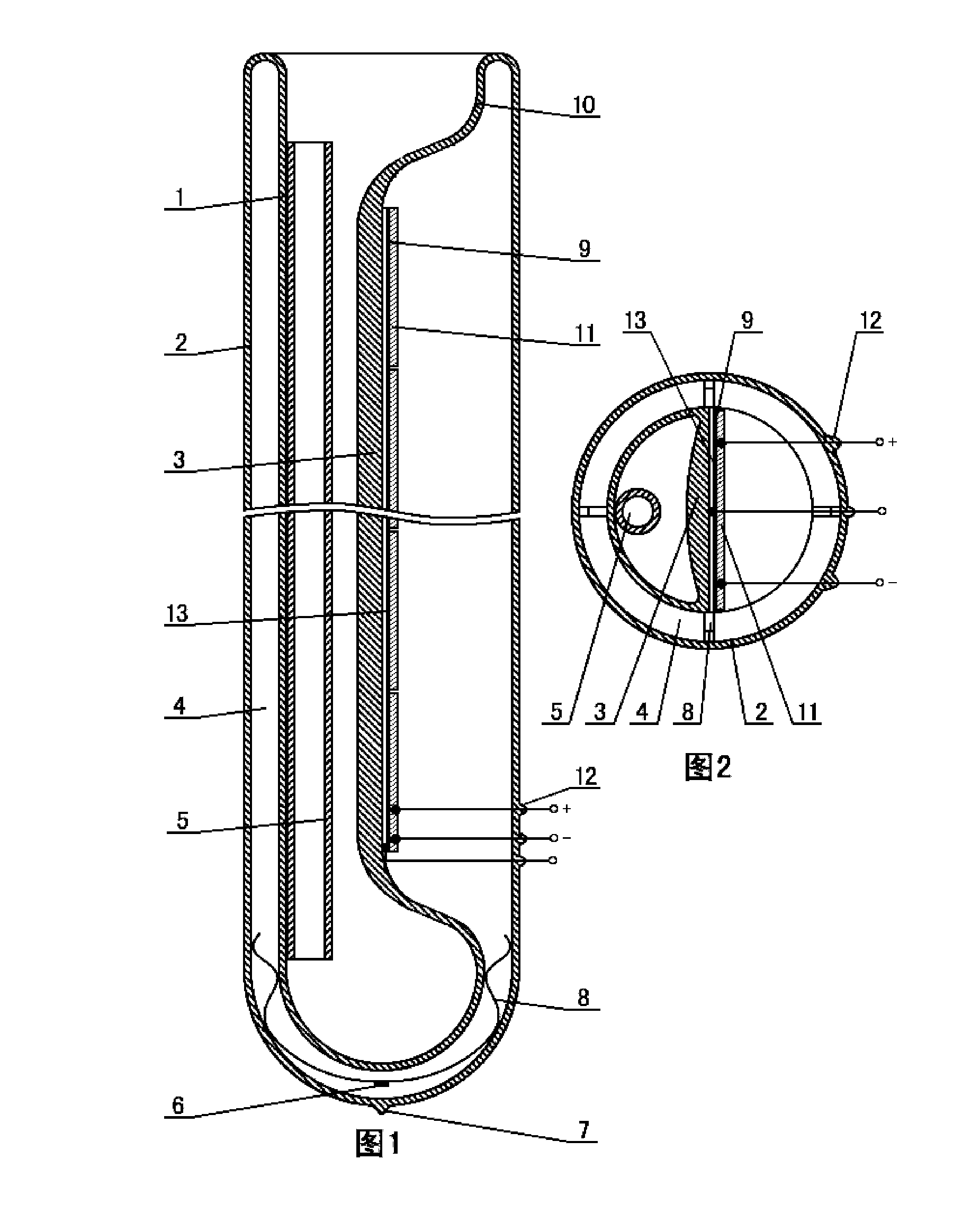

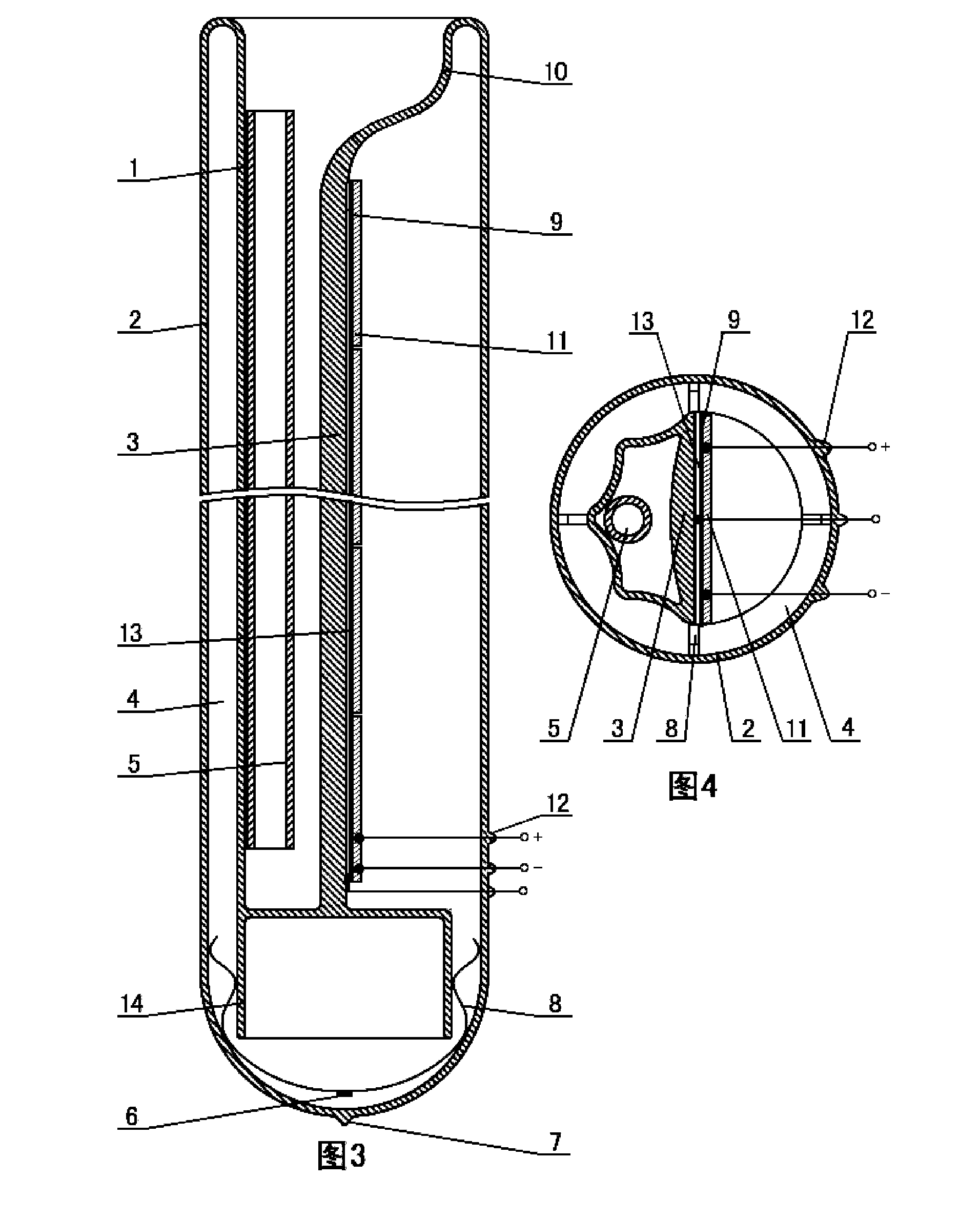

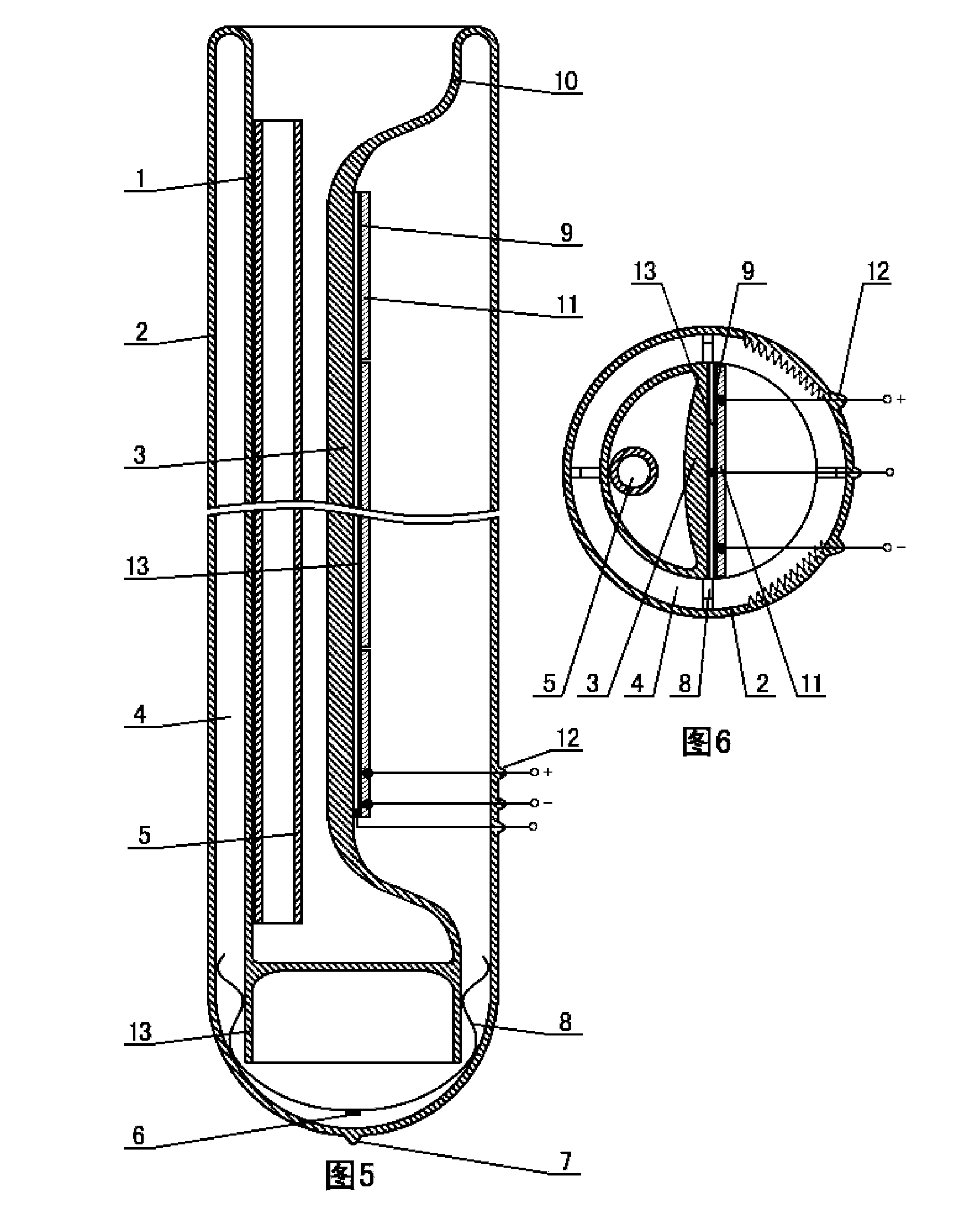

[0038] Such asfigure 1 , figure 2 Shown: an electrostatic anti-scaling all-glass vacuum photovoltaic power generation heat collector equipped with a deflector is composed of a semi-circular flat glass tube arc surface 1, an outer cover glass tube 2, a semi-circular flat glass tube 3, a photovoltaic cell 11, and an exhaust nozzle 7 And air getter 6 composition. One side of the outer wall surface of the semicircular flat glass tube 3 is compounded with a photovoltaic cell 11, and the end of the semicircular flat glass tube 3 and the outer cover glass tube 2 are welded to form a semicircular flat heat collecting glass nozzle with the same center as the semicircular flat glass tube 3 1. The interlayer of the cover glass tube 2 and the semicircular flat glass tube 3 is evacuated through the exhaust nozzle 7 to form a vacuum insulation interlayer 4 , and a getter 6 is installed in the vacuum insulation interlayer 4 . A deflector 5 is installed in the lumen of the all-glass vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com