Calibration device of binocular vision navigation system of lunar surface vehicle

A navigation system and binocular vision technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of insufficient square grid image extraction accuracy, decreased calibration accuracy of the calibration board, and poor stability of the calibration board, so as to ensure the control grid High precision, high uniformity, adjustable brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

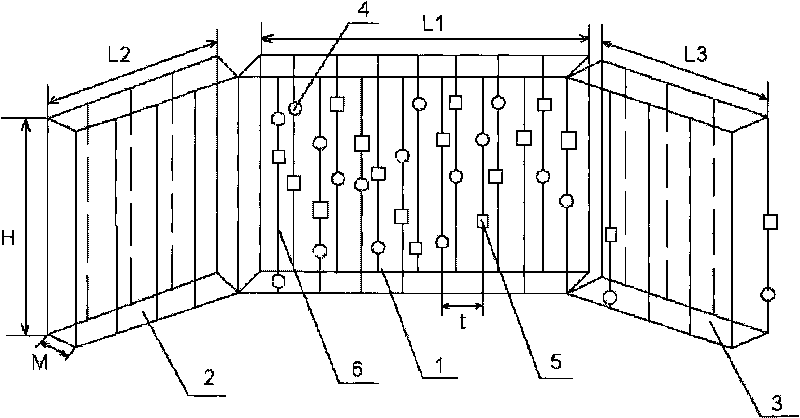

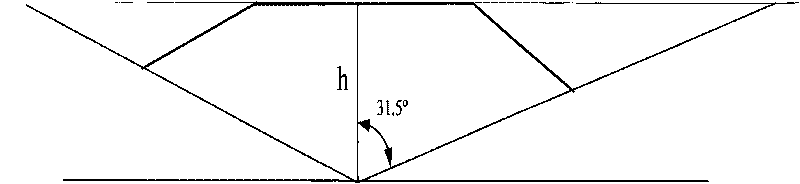

[0020] like figure 1 As shown, the calibration device mainly includes a calibration frame, a retroreflection measurement mark 4, a coding mark 5 and a ring light source. The calibration frame includes the main frame 1, the left auxiliary frame 2 and the right auxiliary frame 3 of the same size. The height H and width M of the frame 3 are the same, the angles between the left auxiliary frame 2 and the right auxiliary frame 3 and the main frame 1 are all obtuse angles, the sum of the lengths of the three frames l and the distance h between the camera and the main frame 1 The relationship between them is l=2htan(w), the length L1 and the height H of the main frame 1 are equal to the distance h between the calibration camera and the main frame 1, and multiple columns of installation bars are arranged staggeredly on the front surface and the rear su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com