Design method of seamless turnouts on elevated station of longitudinally, transversely and vertically coupled high-speed railway

A design method and technology for high-speed railways, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem that can not meet the design needs, can not calculate the deflection force, braking force and space deformation of the seamless switch on the bridge, can not consider the bridge and turnout detail space structure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

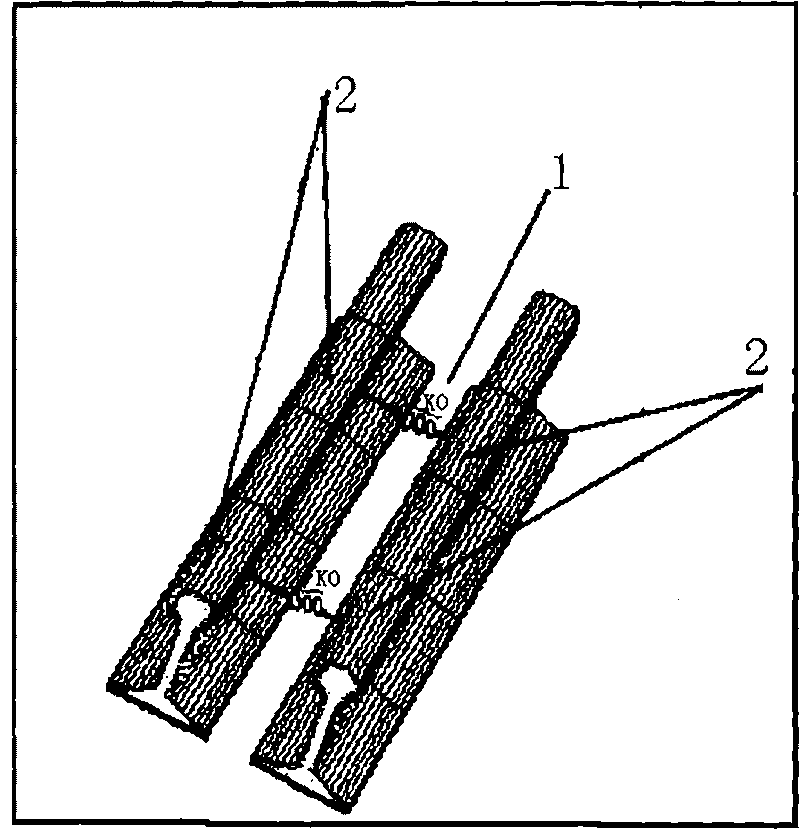

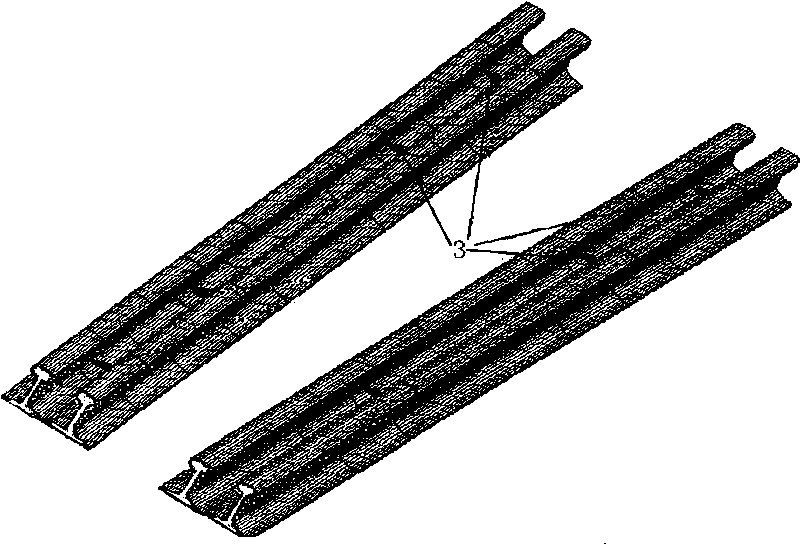

[0098] In this embodiment, the No. 18 ballastless track of the 60kg / m rail passenger dedicated line is seamlessly crossed. The heel of the switch rail adopts two sets of limiter structures (the limit values are 7.0mm and 6.5mm respectively), and the distance between the two lines is 5.0. m as an example to give the calculation results of this method (according to the APDL parametric design language, write the corresponding program to extract the results after the calculation is completed), the crossover plane is as follows Figure 9 shown. The crossing line is located on the 6×32.0m continuous beam, and the two sides of the continuous beam are 3×32.0m simply supported beams. The layout of the continuous beam and the simply supported beam is as follows: Figure 10 shown. The crossing line is located in the middle of the continuous beam joint length, and the distance between the two switch centers is 90m. The longitudinal stiffness of the continuous girder bridge pier top is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com