Conductive device used for narrow-clearance submerged arc welding

A conductive device and submerged arc welding technology, which is applied in the direction of arc welding equipment, electrode accessories, welding rod characteristics, etc., can solve the problems of high maintenance and repair costs, failure to meet requirements, and easy delay in work, so as to ensure welding efficiency and welding quality , high welding efficiency and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

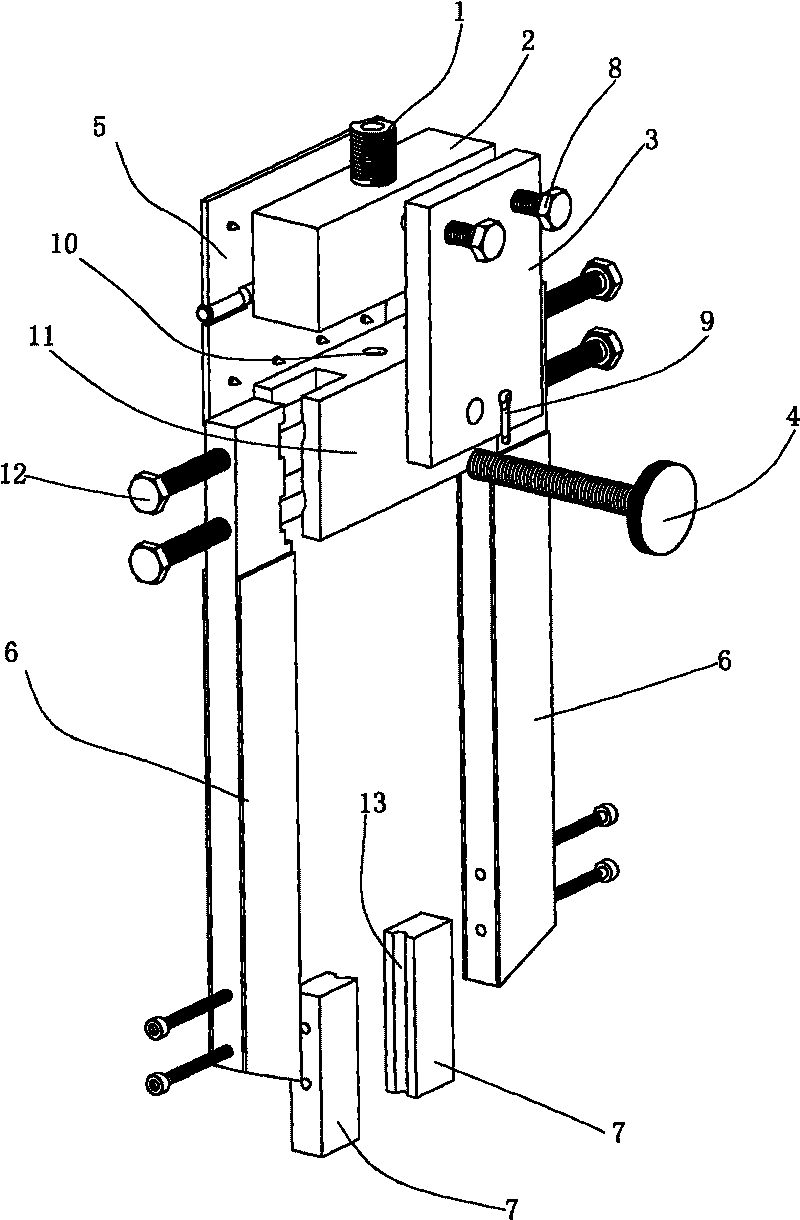

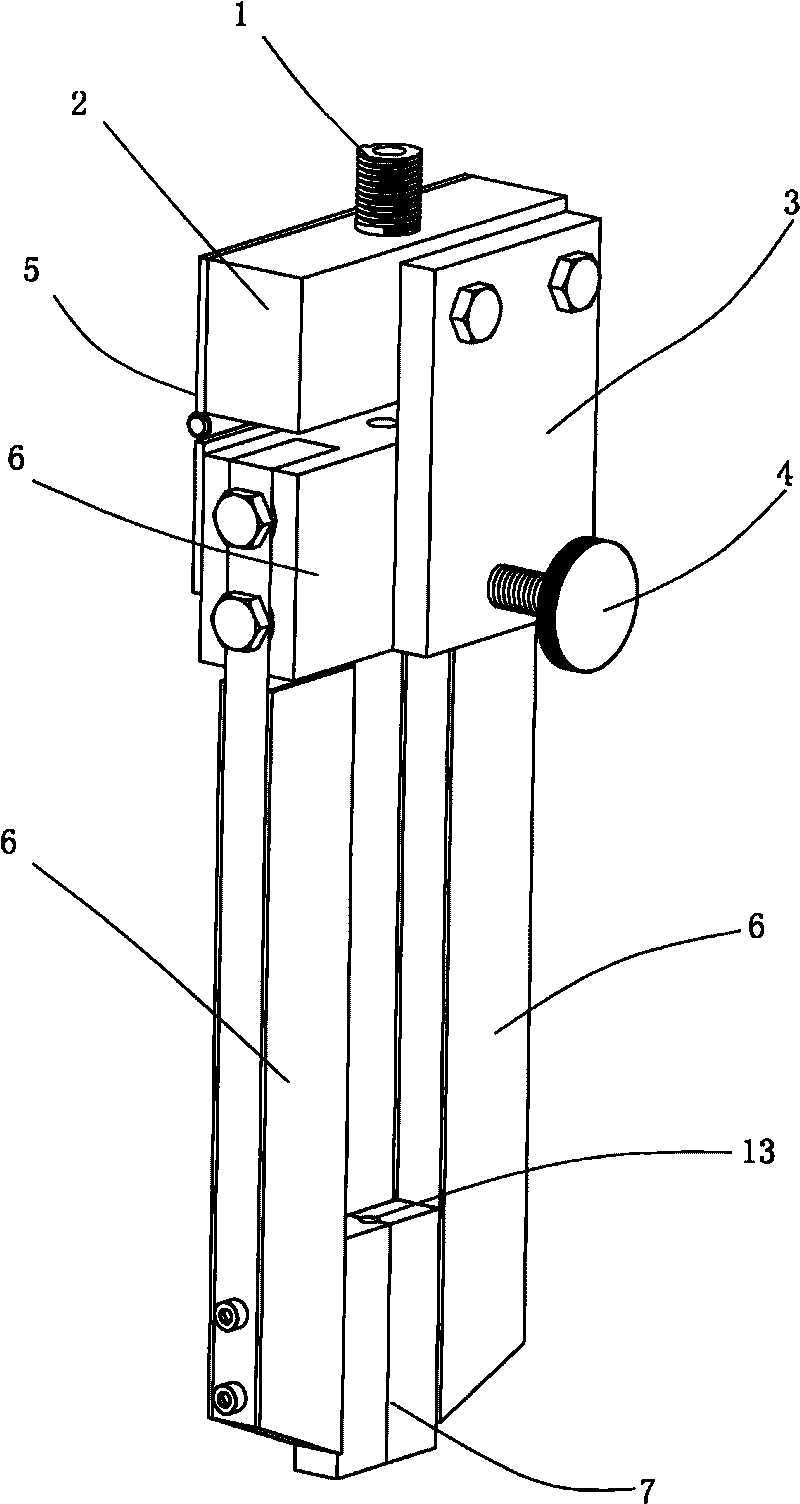

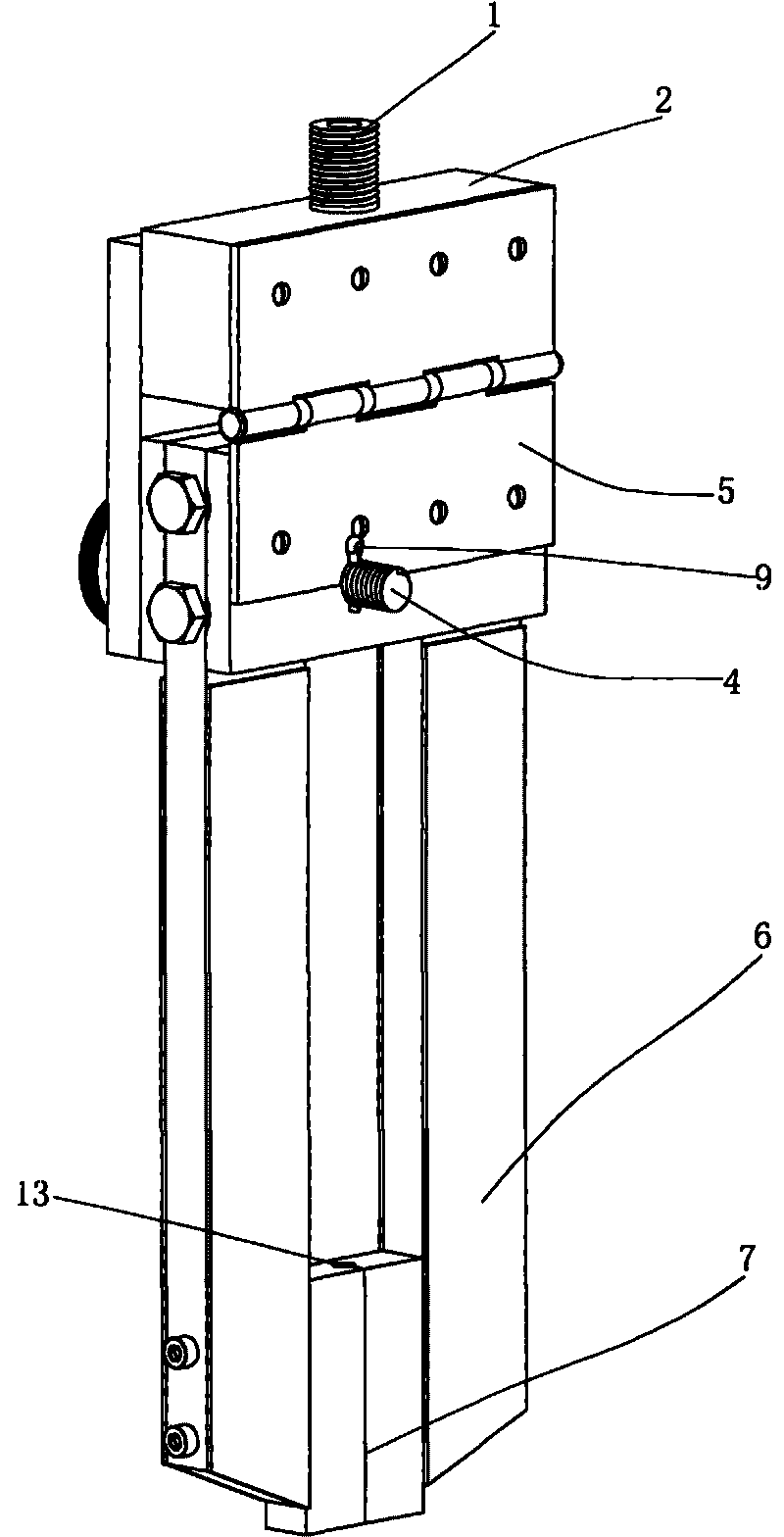

[0014] The conductive device for narrow gap submerged arc welding includes a sleeve 1, a fixing plate 2, a connecting plate 3, a hinge 5, an adjusting hand wheel 4, a bracket, and a conductive nozzle 7 arranged at the lower end of the bracket.

[0015] Wherein, the sleeve 1 is fixed on the fixed plate 2, and the outer part of the sleeve 1 is provided with threads to facilitate the connection between the sleeve 1 and the guide post of an ordinary submerged arc welding machine.

[0016] The bracket is arranged under the fixed plate 2 with a certain gap between the two; the bracket in this embodiment is composed of three parts, namely the beam 11 arranged under the fixed plate 2 and the uprights 6 arranged on both sides of the weight 11, Bolts 12 are used to connect the two uprights 6 and the cross beam 11 together; the cross beam 11 is provided with a hole 10 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com