Spherical surface defect detection method based on machine vision

A defect detection and sphere technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of increasing maintenance costs and complex structure of the detection system, and achieve the effect of low maintenance costs, simple structure of detection equipment, and improved inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

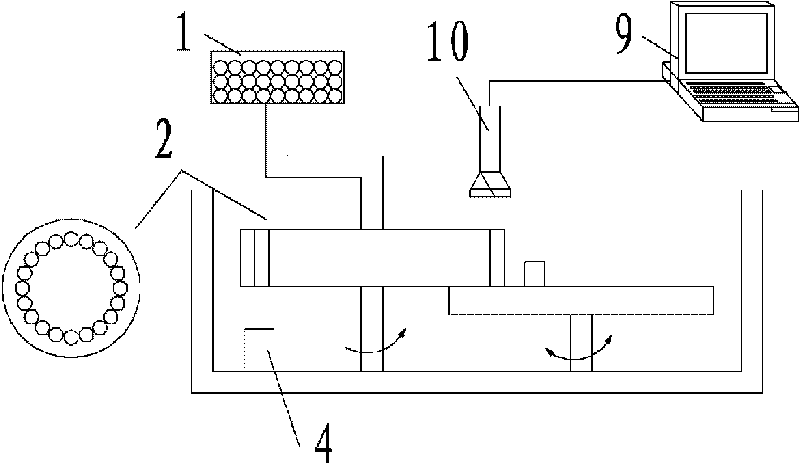

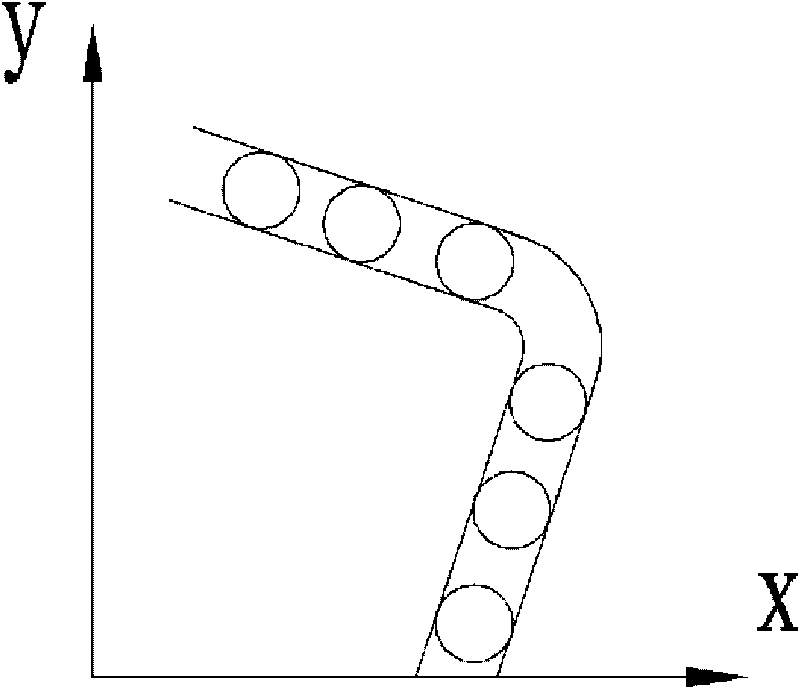

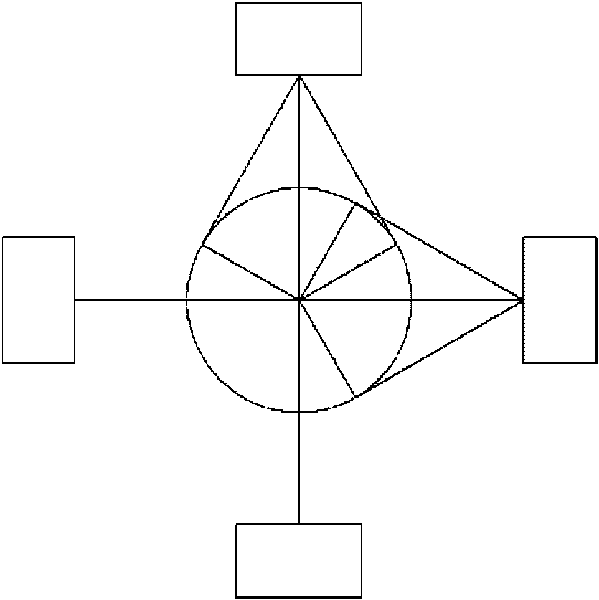

[0022] The present invention is based on the machine vision-based sphere surface defect detection method, which adopts the method of moving the sphere to be tested along the figure 2 The pure rolling is performed on the two mutually perpendicular and interconnected tracks, and a pit is set at the junction of the two tracks. When the ball moves to the junction of the two tracks, it stops rolling under the action of the pit, and then the trigger Push the ball to make it roll to another track that is perpendicular to each other. The two tracks are set vertically and the pits are set at the junction to ensure that the ball is doing pure rolling on the track. In this way, the camera set above the track collects Only the image information of the sphere can cover the entire position of the sphere, and there will be no missed acquisition areas. image 3 As shown, there are four cameras distributed on the equatorial plane of the sphere, and two branches are located on the plane perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com