Method and system for decelerating pneumatic delivery of pebble bed reactor fuel elements

A fuel element and deceleration system technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve the uncertainty of the adjustment of fuel element outlet speed, can not realize the detection of fuel element running speed, and increase the pipeline system structure The difficulty of complex equipment maintenance and other issues, to achieve high reliability, high safety requirements, simple system structure and control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

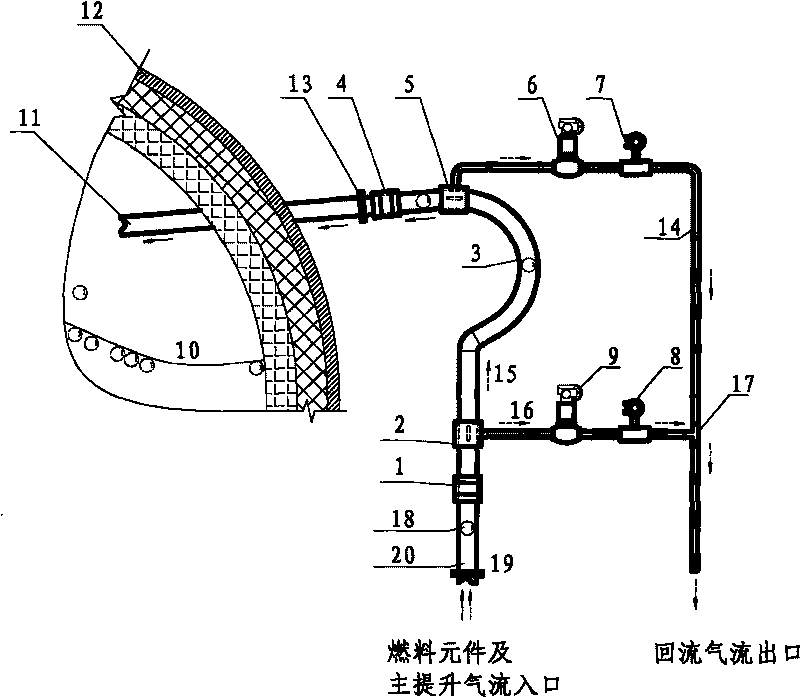

[0033] The present invention proposes a method for decelerating the pneumatic conveying of pebble bed reactor fuel elements, the decelerating method comprising:

[0034]Under the action of the main lift air flow, the fuel elements run at high speed from the bottom to the top along the pneumatic conveying pipeline outside the core or other containers; Part of the main lift airflow remains in the element conveying pipe, and its conveying direction is consistent with the running direction of the fuel elements; before the fuel elements enter the core or other containers, the split main airflow is all drawn out of the fuel element conveying pipe, and the fuel elements flow into the stack by gravity core or other container; the divided main lift air flow can be merged with the drawn partial air flow to form a return flow; the inlet pressure of the main air flow and the extraction of the return gas can be provided separately by a compressor or other gas delivery equipment;

[0035] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com