Cubic apparatus for tetrahedron press

A technology of six-sided roof and tetrahedron, which is applied in the field of six-sided roof of tetrahedron press, can solve the problems of large volume and weight of pin shaft, large volume of hinge beam, short service life, etc., and achieve simple force, firm structure, The effect of reducing the chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

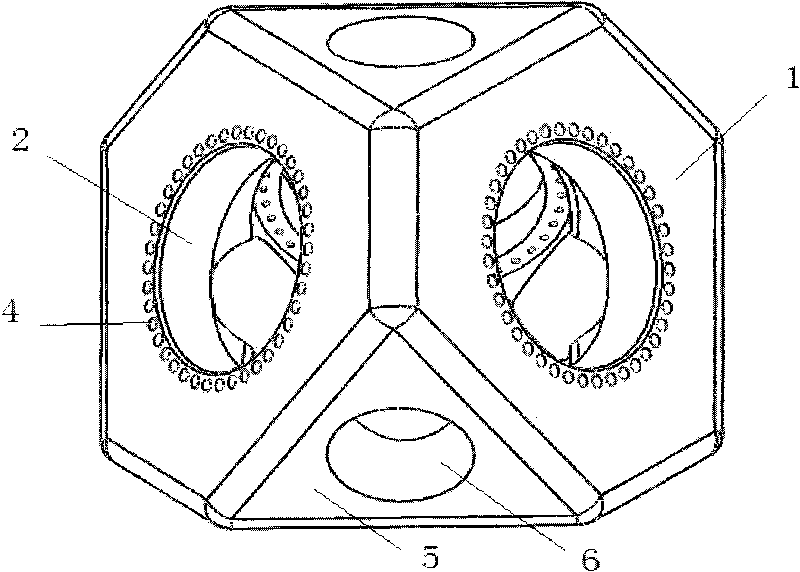

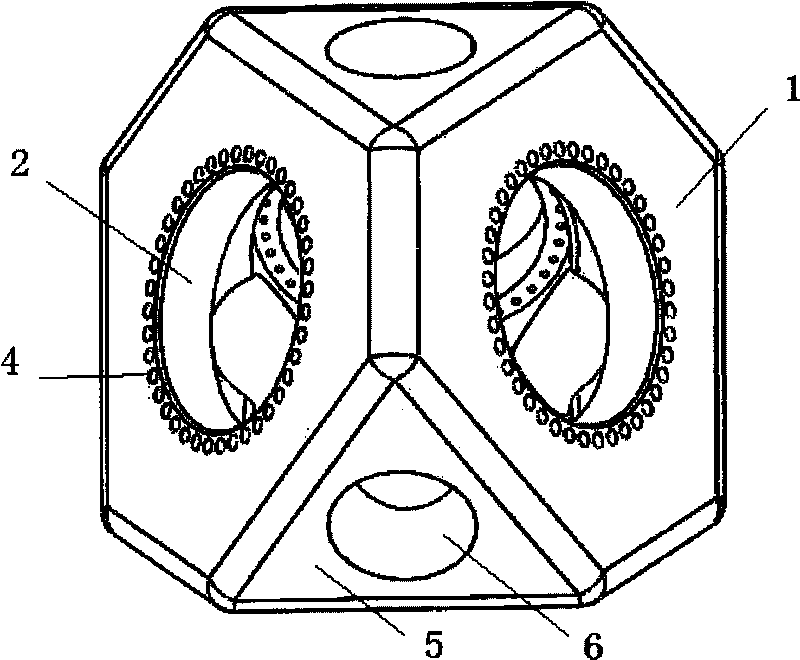

[0014] like figure 1 , 2 As shown, the present invention includes a hexahedron substrate 1, which is characterized in that: the hexahedron substrate 1 is formed by truncating four corners of a hollow regular tetrahedron, wherein the cross-sections of the corners of a regular tetrahedron are four identical Equilateral triangular planes 5 are provided with channel holes 6 communicating with their hollow parts at the central parts of the four regular triangular planes 5, and oil cylinders communicating with their hollow parts are provided at the central parts of the remaining four faces of the six-sided roof base 1. Flange hole 2.

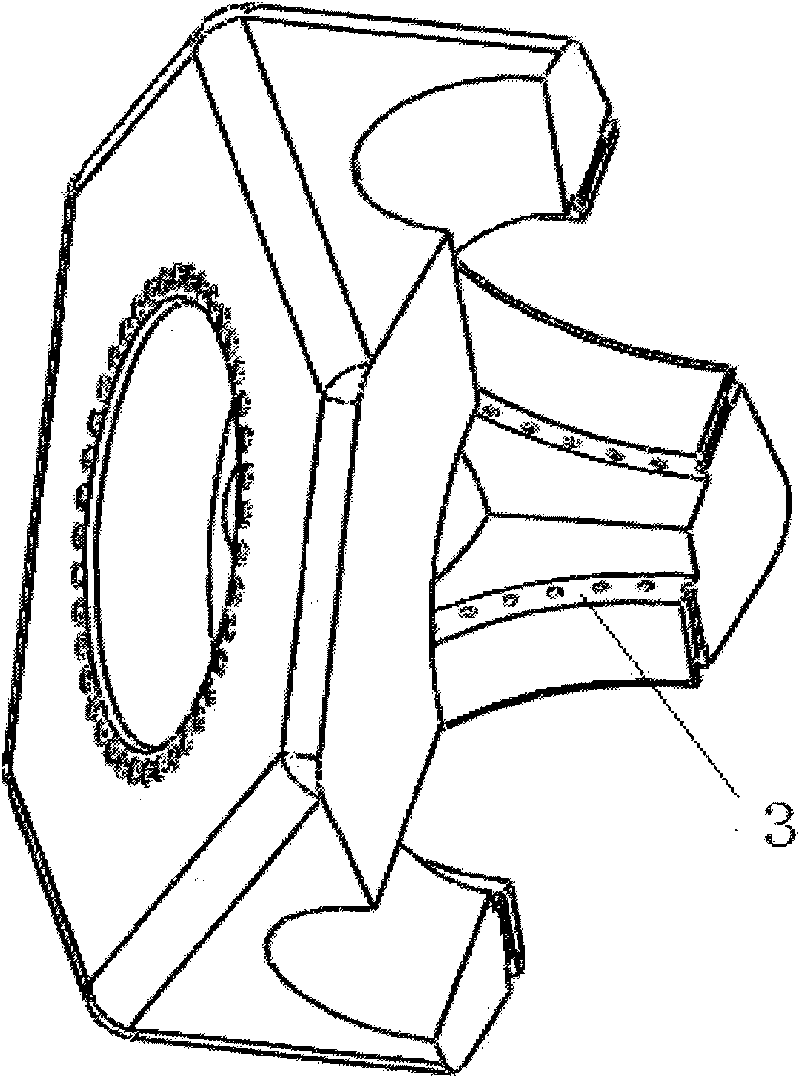

[0015] A step 3 is provided on the outer edge of the cylinder flange hole 2 close to the hollow part of the six-sided roof base 1 .

[0016] The edges of the six-sided roof base 1 are arc-shaped.

[0017] The step 3 is provided with a counterbore 4 penetrating through the six-sided roof base 1 .

[0018] The edge length of the hollow regular tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com