Sprue cup for smelting alloy

A pouring cup and alloy technology, which is applied to metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of limited filtering effect of the filter screen, affecting the quality of alloys, removal, etc., to achieve good application prospects, improve quality, The effect of reducing the impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

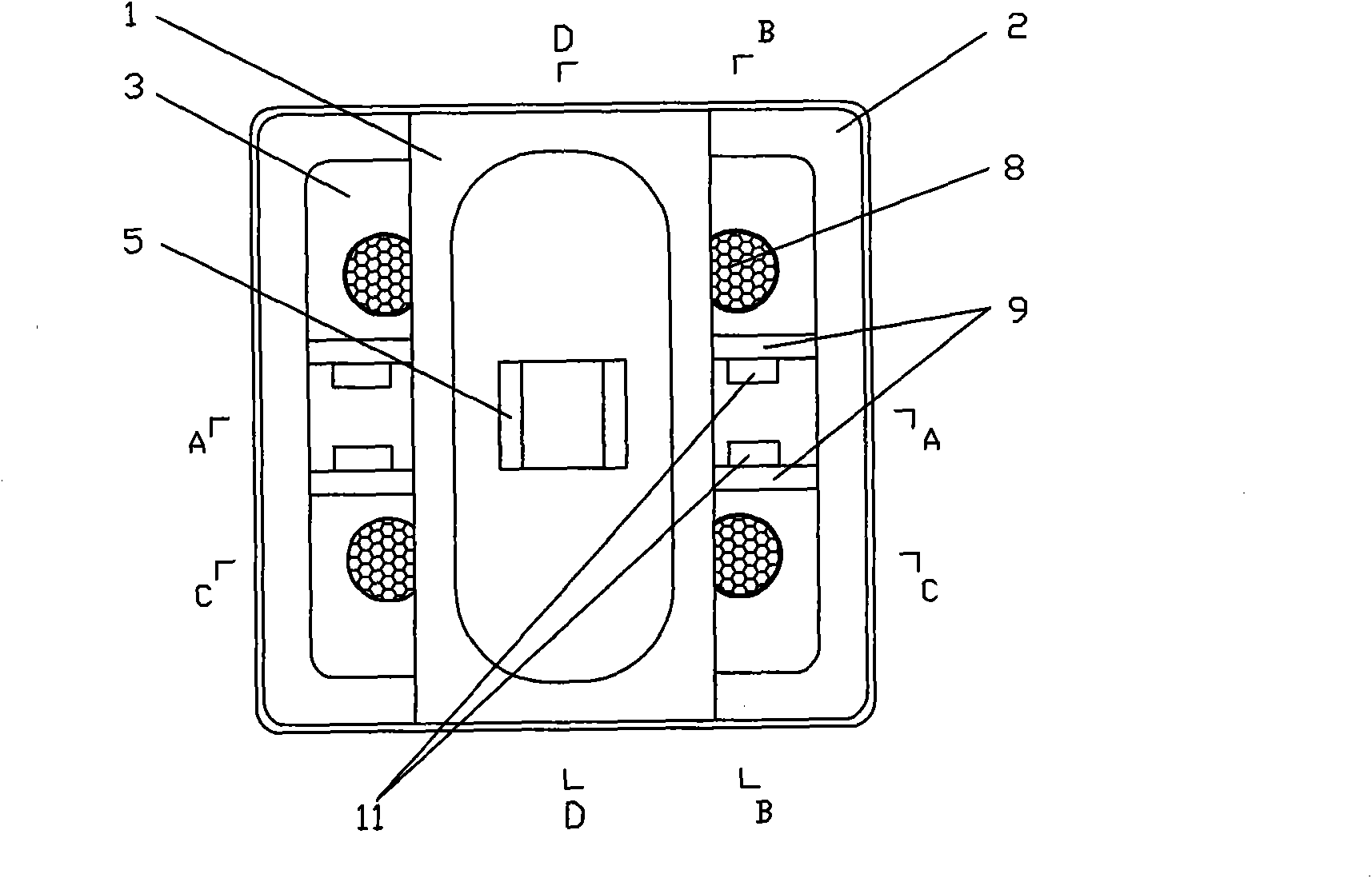

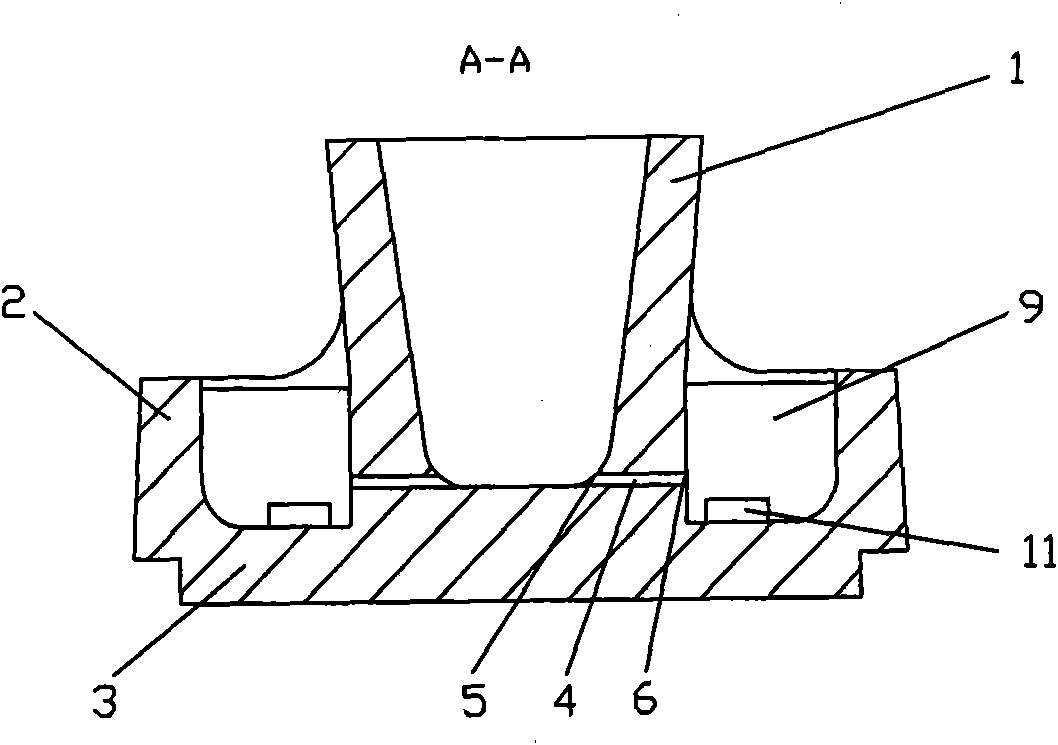

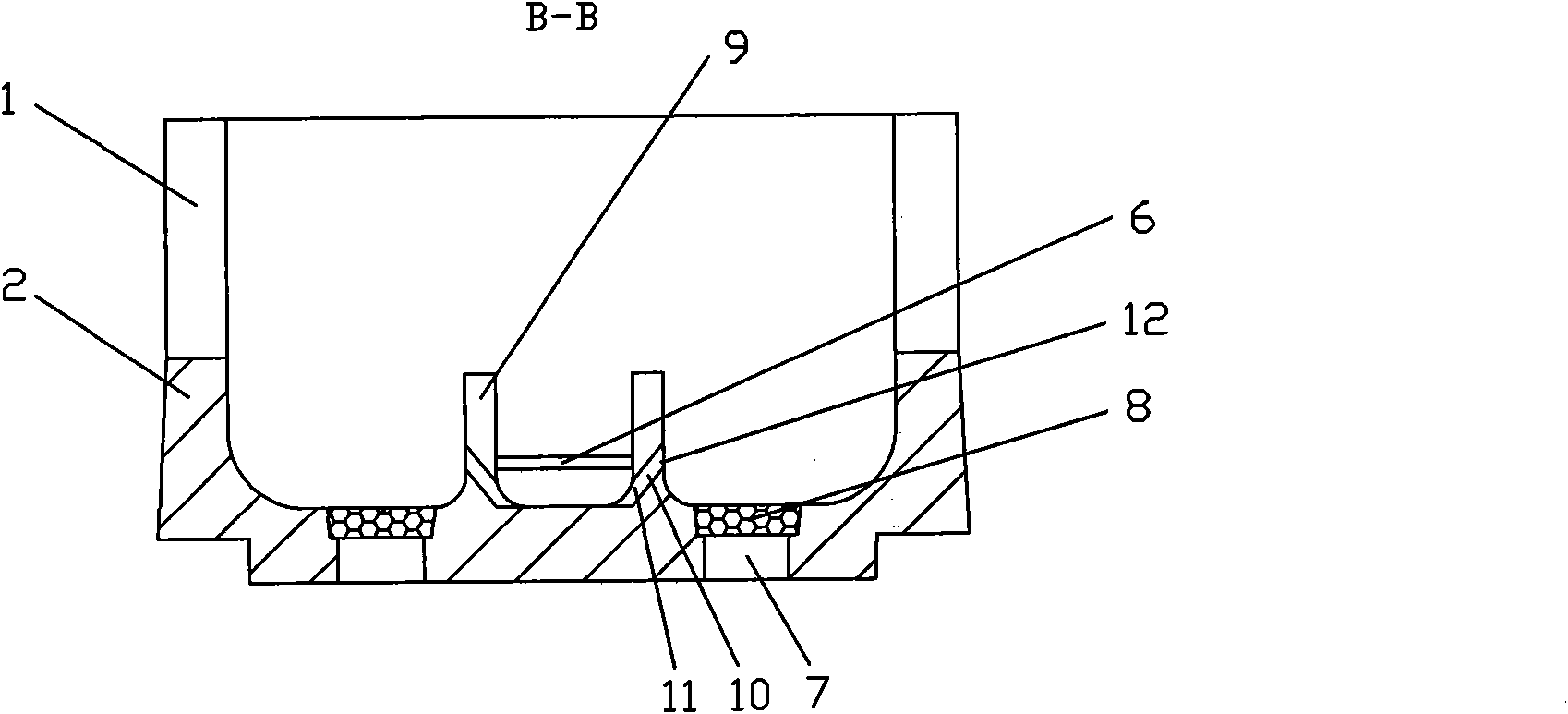

[0021] The structure of sprue cup for alloy melting is as follows: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the sprue cup is mainly composed of an inner cup wall 1, an outer cup wall 2 and a bottom plate 3 shared by both. The bottom plate 3 is provided with a filter port 7, and a filter screen 8 is provided on the filter port 7. The inner cup The bottom of the wall 1 is provided with two melt channels 4, the opening of the melt channel 4 on the inner side of the inner cup wall 1 is the melt channel inlet 5, and the opening of the melt channel 4 on the outer side of the inner cup wall is the melt Passage exit 6.

[0022] Four dams 9 are arranged between the inner cup wall 1 and the outer cup wall 2, and the dams 9 are located between the melt channel outlet 6 and the filter port 7; the level height of the dams 9 is smaller than that of the outer cup wall 2, The height difference is 2mm. The side of the dam 9 opposite to the outlet 6 of the melt ch...

Embodiment 2

[0026] The structure of the sprue cup for alloy smelting is the same as in Example 1, except that the horizontal height of the dam is equal to the horizontal height of the outer cup wall; the height difference between the highest point of the entrance of the slag channel and the lowest point of the outlet of the slag channel is 5mm.

Embodiment 3

[0028] The structure of the sprue cup for alloy smelting is the same as that in Embodiment 1, except that the height difference between the highest point of the entrance of the slag holding channel and the lowest point of the exit of the slag holding channel is 10mm.

[0029] The above-mentioned sprue cup is used for pouring, and the alloy melt is poured into the inner cup wall, and the floating impurities are in the dam and do not enter the filter port. If the molten steel is very dirty and contains large pieces of slag inclusions to block the slag holding port, the alloy liquid will flow into the filter port through the top of the dam, reducing the problem of fire escape. Compared with the original sprue cup without a dam, the impurities in the alloy ingot are significantly reduced, and the reject rate of the produced product is reduced by 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com