Automatic leveling and adjusting lifting appliance and control method thereof

An automatic leveling and hoisting technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of personnel and equipment loss, low work efficiency, and damage to suspended objects, and achieve high leveling accuracy and convenient operation , adjust the effect of posture flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

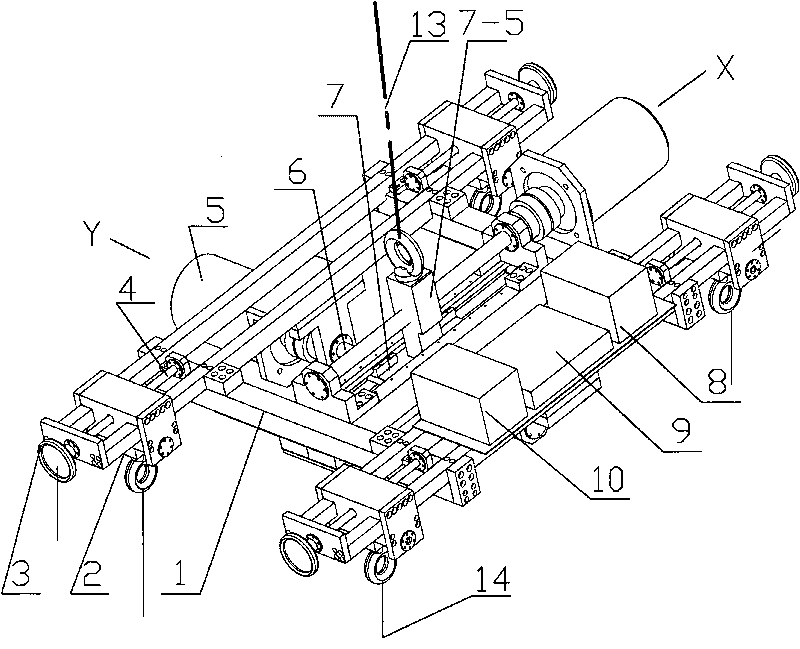

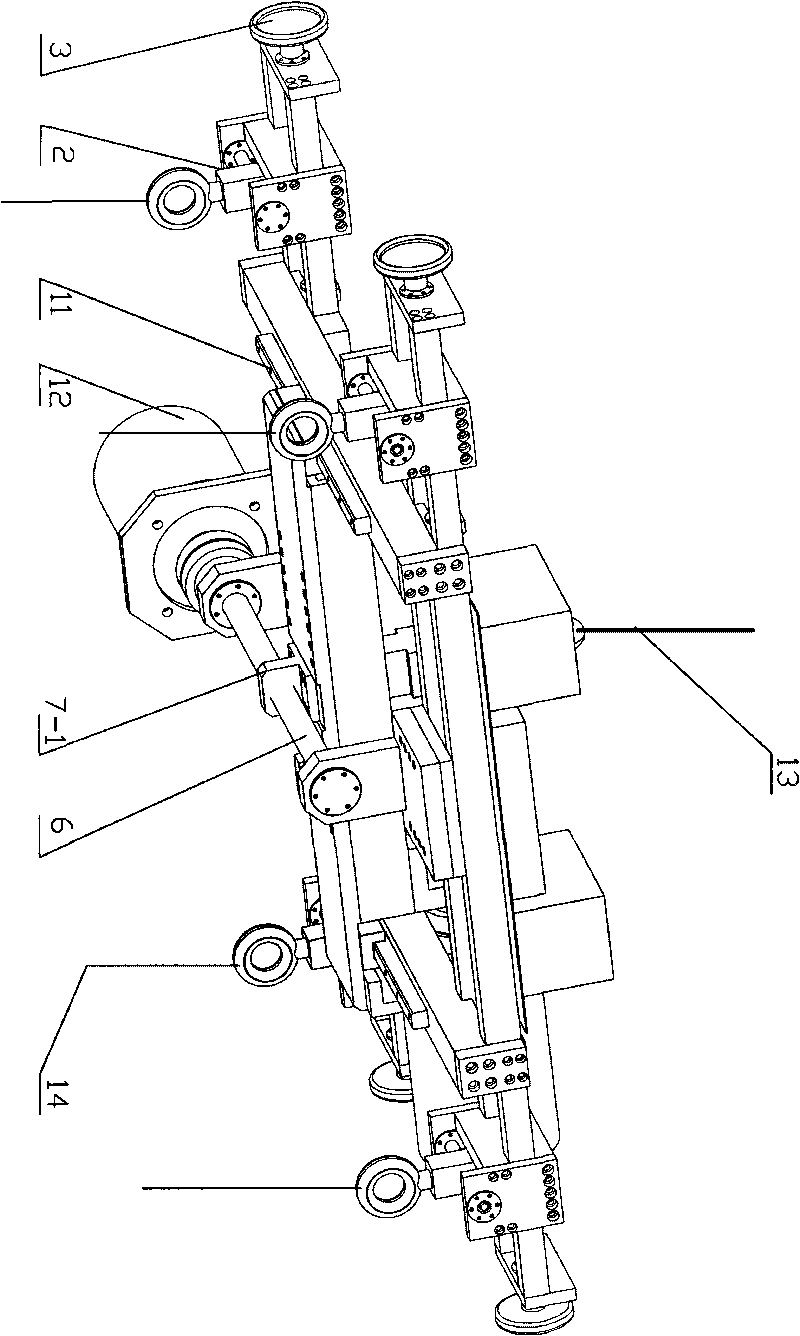

[0035] like figure 1 , figure 2 As shown, an automatic leveling and attitude-adjusting spreader includes: a plane frame-shaped frame 1 composed of four long and two short beams fixedly connected by bolts; Suspension device 2 and hoisting device 7-5 for hanging objects to be hung;

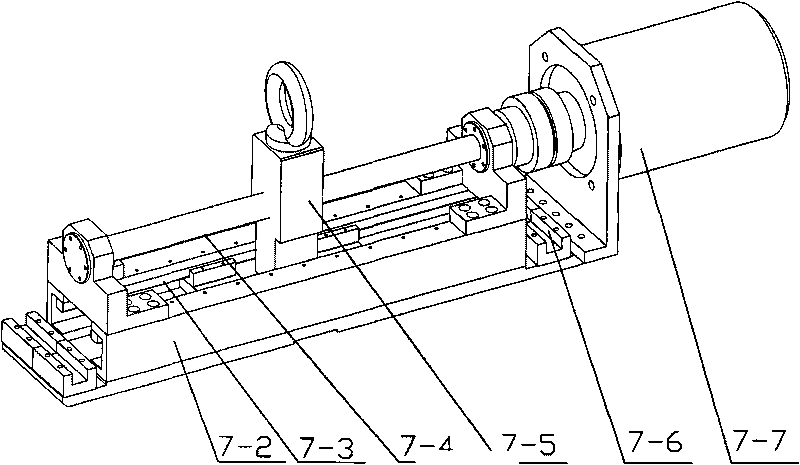

[0036] a. The frame is equipped with a y guide rail 11, and a slide device 7 that moves the lifting device 7-5 upwards in x is installed on the guide rail; the y direction driving mechanism of the slide device is housed on the frame;

[0037] b. the lifting device 7-5 is mounted on the sliding device;

[0038] c. The rack is also equipped with XW-TS1100 type tilt sensor 8, system controller 9 and drive motor circuit device 10 composed of two 3.7KW frequency converters; the two frequency converters are respectively used to drive X-direction and y-direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com