Sewage treatment method and device thereof

A sewage treatment method and technology of a sewage treatment device, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, centrifugal separation water/sewage treatment, etc., can solve the problems of large investment and waste of sewage treatment equipment, Achieve the effect of saving one-time investment, low head loss and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

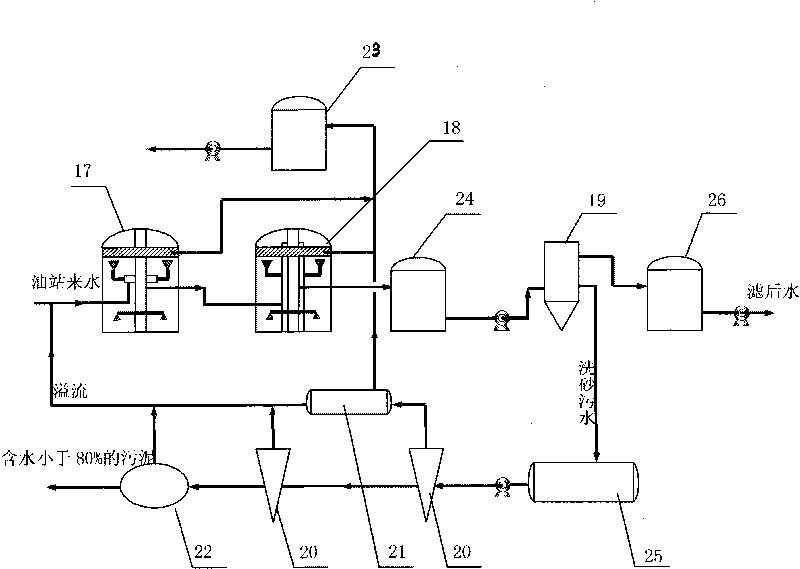

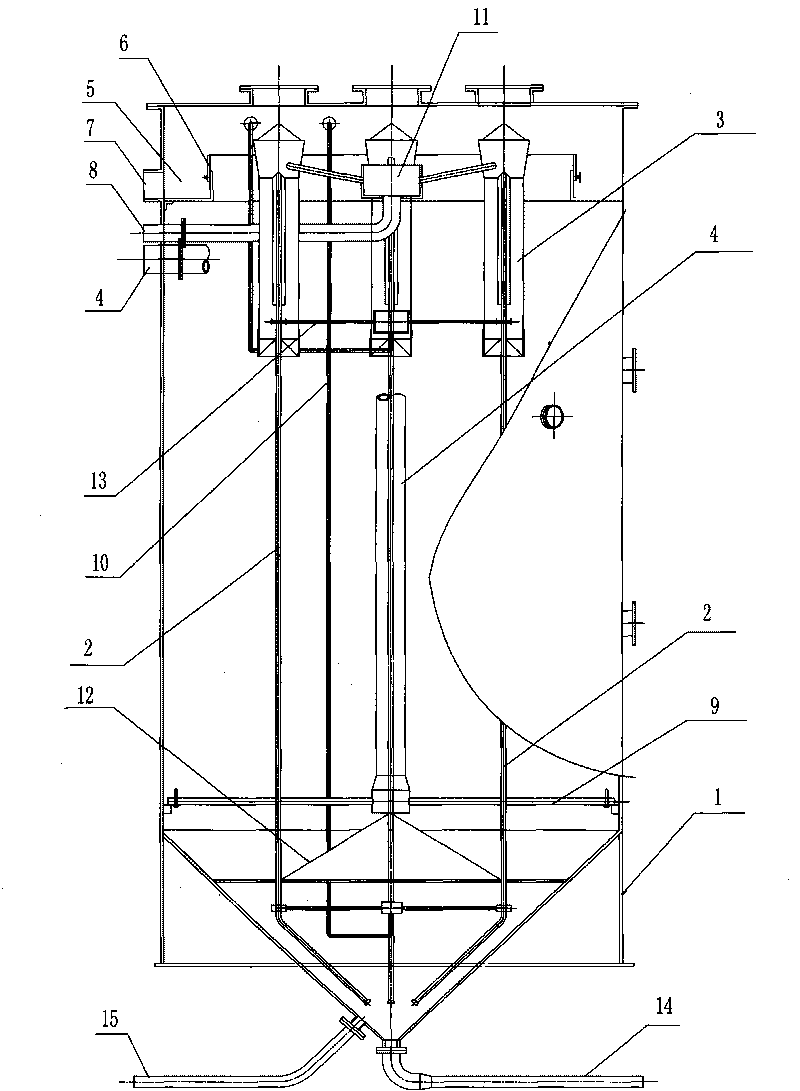

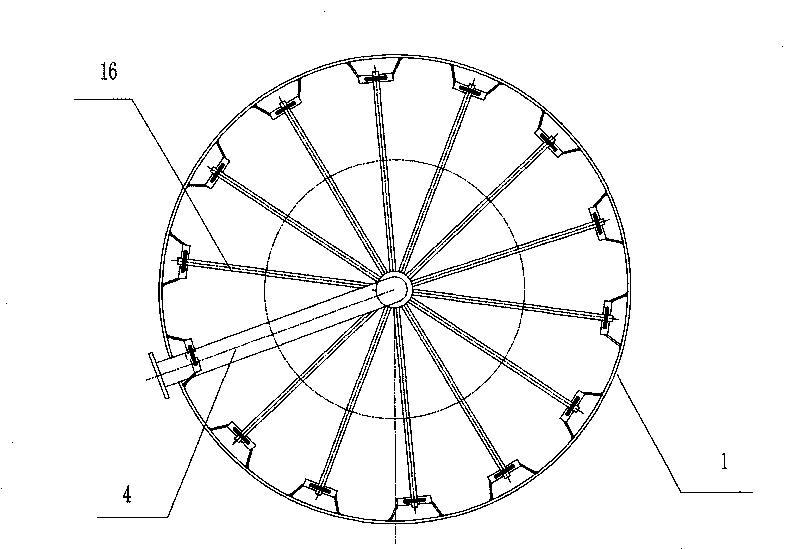

[0024] Such as figure 1 As shown, this sewage treatment device comprises a settling tank, a continuous automatic sand filter 19, an oil sludge thickening system, and a waste oil tank 23. There are two settling tanks, which are respectively a primary settling tank 17 and a secondary settling tank 18. The settling tank 17 is a natural settling tank, the secondary settling tank 18 is a coagulation settling tank, the water outlet of the primary settling tank 17 is connected with the water inlet of the secondary settling tank 18 through a pipeline, and the larger suspended particles are removed by two-stage settling and heavy oil; the water outlet of the secondary settling tank 18 is connected with the water inlet pipe 4 of the continuous automatic sand filter 19 through a pipeline; 24 and a pump; the water outlet 7 of the continuous automatic sand filter is connected to the filtered water tank 26, the clear water filtered by the continuous automatic sand filter is transported to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com