Method and device for automatically controlling coal gas recovery of converter

A converter gas and gas technology, applied in the direction of manufacturing converters, etc., can solve the problems such as the inability to take into account the gas recovery calorific value and the reduction of the recovered calorific value, and achieve the effects of stable and efficient gas supply, reducing waste, and ensuring the recovery amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

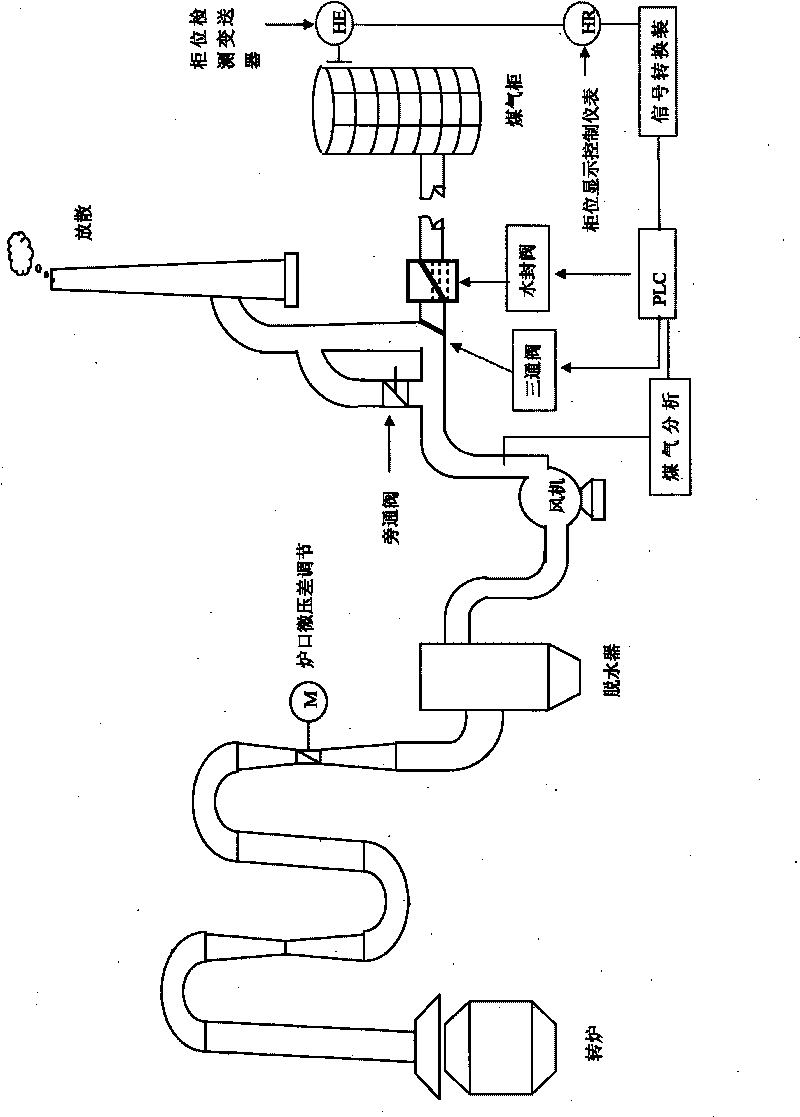

[0016] The converter gas recovery system includes the converter, the gas recovery pipeline and the gas cabinet. On the recovery pipeline, there is a furnace mouth micro-pressure adjustment device, a dehydrator and a fan. There is a gas analyzer (model: EL1020) behind the fan. The recovery pipe behind the fan is The road is connected to the storage gas cabinet and the chimney respectively through the three-way valve. There is a water seal valve in front of the gas cabinet. The gas cabinet has a cabinet position detection transmitter (model: JCA) and a cabinet position display control instrument (DMR2180 paperless recorder) . The detection signal of the counter and the output signal of the gas analyzer are sent to the PLC, and the PLC controls the opening and closing of the three-way valve and the water seal valve through the program to determine whether to recover the gas or stop the recovery of the gas.

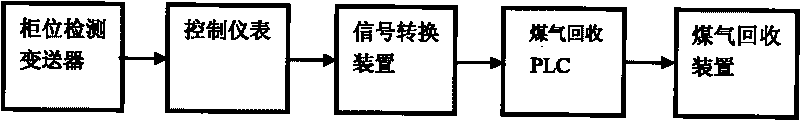

[0017] The control circuit of the present invention is: the angular disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com