Method for anti-seepage construction between hidden frame glass window and building structure

A technology for building structures and glass windows, applied in the direction of sealing devices, joint fastening/covering, etc., can solve the problem of glue surface aging, cracking, falling off, infiltration into the room, and difficult to control the compactness and continuity during filling and filling, etc. problems, to achieve the effect of convenient construction and prevention of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific implementation steps.

[0020] 1. Installation steps

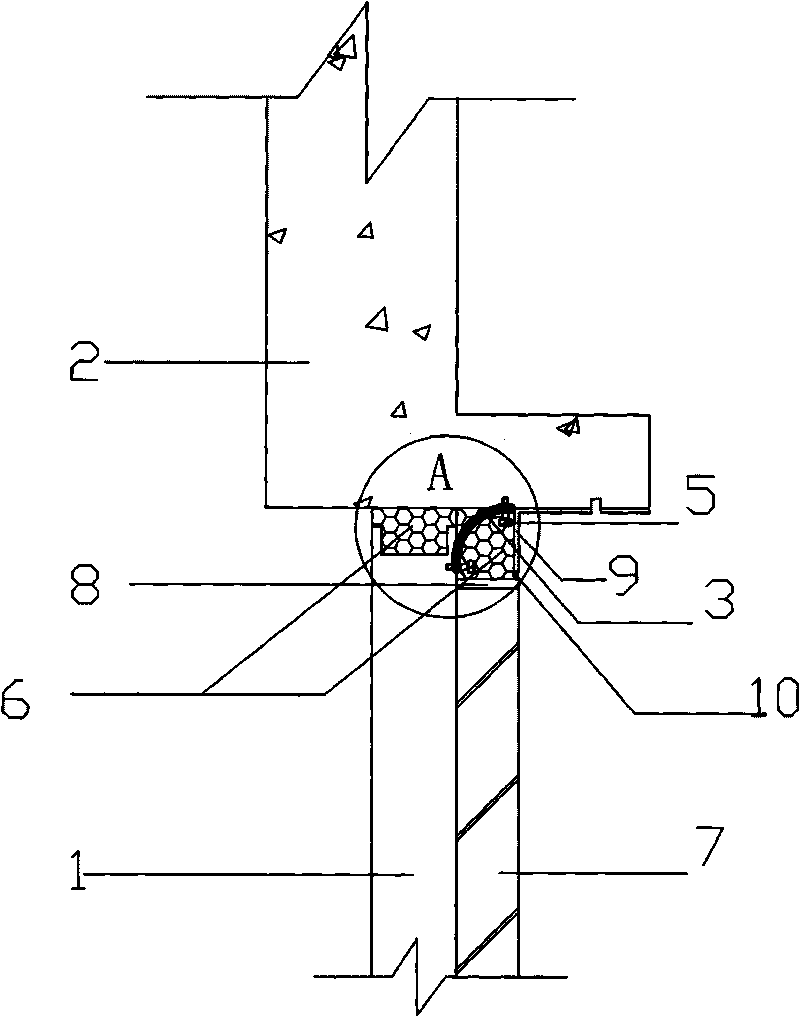

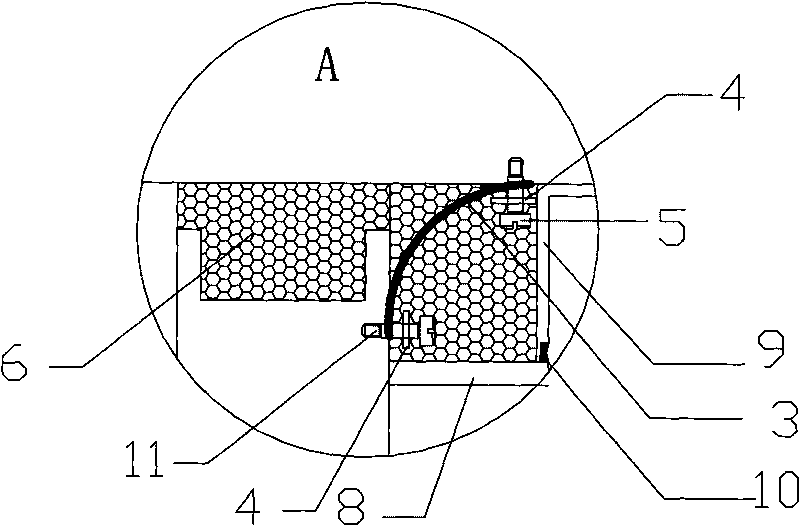

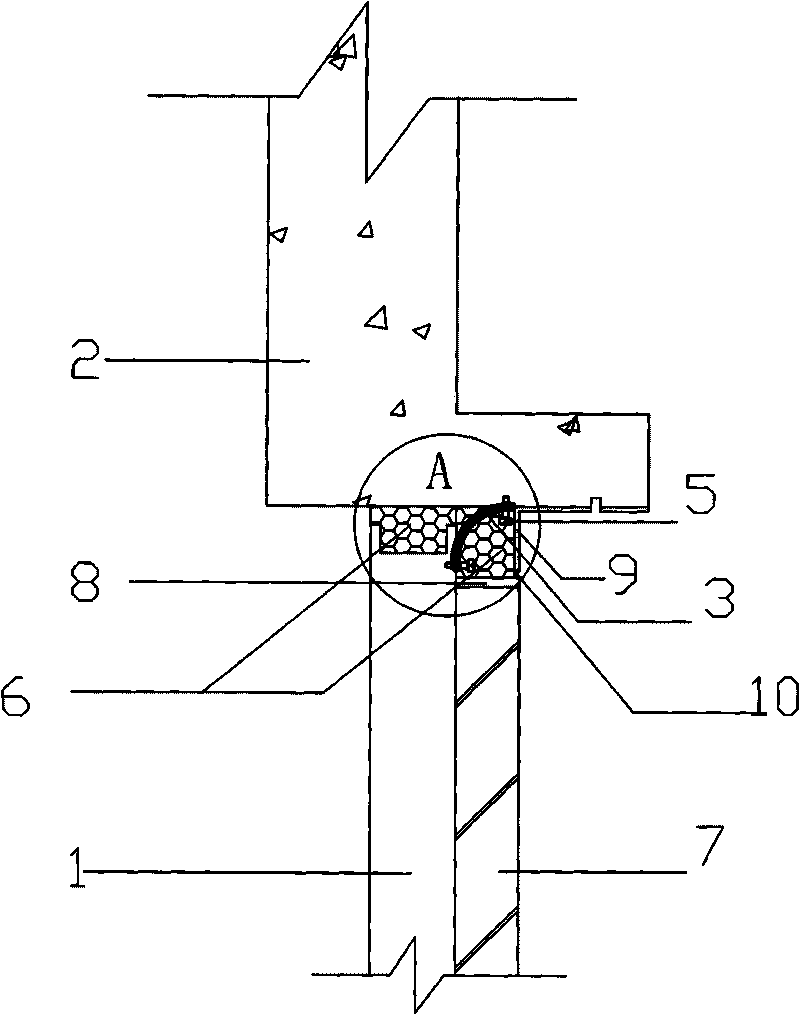

[0021] Such as figure 1 and figure 2 shown.

[0022] 1.1 Waterproof sheet installation

[0023] 1) Cut the waterproof sheet 3 made of EPDM rubber according to the distance between the outside of the window frame 1 and the building structure 2 and the shape of the structural surface.

[0024] 2) Apply waterproof paste on the back of the waterproof sheet 3 with a width of 30 mm on both edges (specifically the same as the overlapping width of the waterproof sheet and the base layer), and then lay it in sections on the base layer of the building structure 2 and the outside of the window frame 1. Pay attention to the waterproof paste It should be applied evenly without missing coating, so as not to affect the bonding effect, but it should not be overcoated, so as to prevent overflow from polluting the structural surface and window fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com