Static balancing method of whole propeller combination of adjustable pitch propellers

A technology of static balance and controllable pitch propellers, which is applied in the field of static balance of controllable pitch propellers and marine adjustable pitch propellers. It can solve the problems of narrow application range and difficult operation, and achieve convenient operation , Improve production efficiency, save judgment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the following, a five-blade propeller is taken as an example to further illustrate a static balancing method for a controllable pitch propeller.

[0030] The weight of the entire propeller: 12635kg, propeller diameter: 4.1m, speed: 208r / min, manufacturing precision: IS0484, Class I, the unbalanced moment Mp of the whole propeller is 7301.1kgmm

[0031] Firstly, the unbalance value M1 of the hub assembly 1 is measured as 1825.3kgmm according to the above method.

[0032] Then measure the unbalance value M2 of the blade group, the steps are as follows:

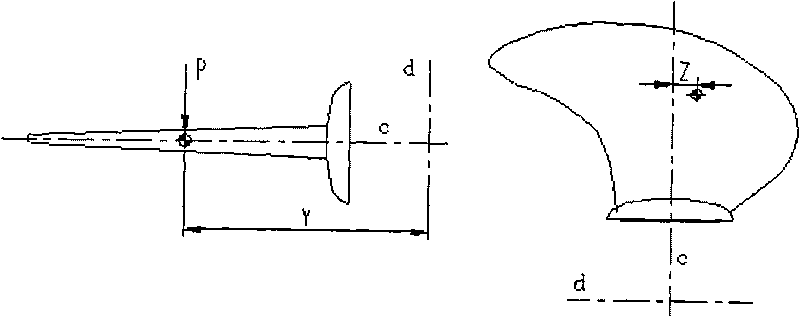

[0033] The static balance test data of each blade is as follows:

[0034] Numbering

Furnace batch number

P(Kg)

Y(mm)

Z(mm)

1

27-05-6-16-1

1156

1016.5

197

2

27-05-6-16-2

1156

1016

195

3

27-05-6-16-3

1156

1015.5

199

4

27-05-6-16-5

1156

1014.5

197

5

27-05-8-26-2

1156

...

Embodiment 2

[0083] The following takes a four-blade propeller as an example to further illustrate a static balancing method for a controllable pitch propeller.

[0084] The weight of the whole propeller of the four-blade propeller: 11530kg, propeller diameter: 4.2m, rotational speed: 179.3r / min, manufacturing precision: IS0484, Class I. The unbalanced moment Mp of the whole paddle: 8966.3kgmm.

[0085] Firstly, the unbalance value M1 of the propeller hub assembly 1 is measured as 2241.6kgmm according to the above method.

[0086] Then measure the unbalance value M2 of the blade group, the steps are as follows:

[0087] The static balance test data of each blade is as follows:

[0088] Numbering

Furnace batch number

P(Kg)

Y(mm)

Z(mm)

1

28-06-3-22-2

1337

993

257

2

28-06-3-22-3

1336

997

257

3

28-06-3-22-4

1336

996.5

265

4

28-06-3-22-5

1337

995

260

...

Embodiment 3

[0116] The following takes a three-blade propeller as an example to further illustrate a static balancing method for a controllable pitch propeller.

[0117] The weight of the whole propeller of the three-blade propeller: 9630kg, the diameter of the propeller: 4.1m, the speed of rotation: 208r / min, the manufacturing precision: IS0484, Class I, the unbalanced moment Mp of the whole propeller: 5564.7kgmm.

[0118] Firstly, the unbalance value M1 of the hub assembly 1 is measured as 1391.2kgmm according to the above method.

[0119] Then measure the unbalance value M2 of the blade group, the steps are as follows:

[0120] The static balance test data of each blade is as follows:

[0121] Numbering

Furnace batch number

P(Kg)

Y(mm)

Z(mm)

1

29-07-3-28-1

1155

1013.5

205

2

29-07-3-28-2

1152

1014.5

200

3

29-07-3-28-3

1154

1012

203

[0122] see image 3 , P is the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com