Rigidity testing device of fixed type metal sheet stamping part

A metal sheet and testing device technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of inability to guarantee accuracy, non-standardization, scientificity, and no fixed stiffness testing device for sheet metal stamping parts, etc., to achieve compact structure, work Efficiency improvement, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

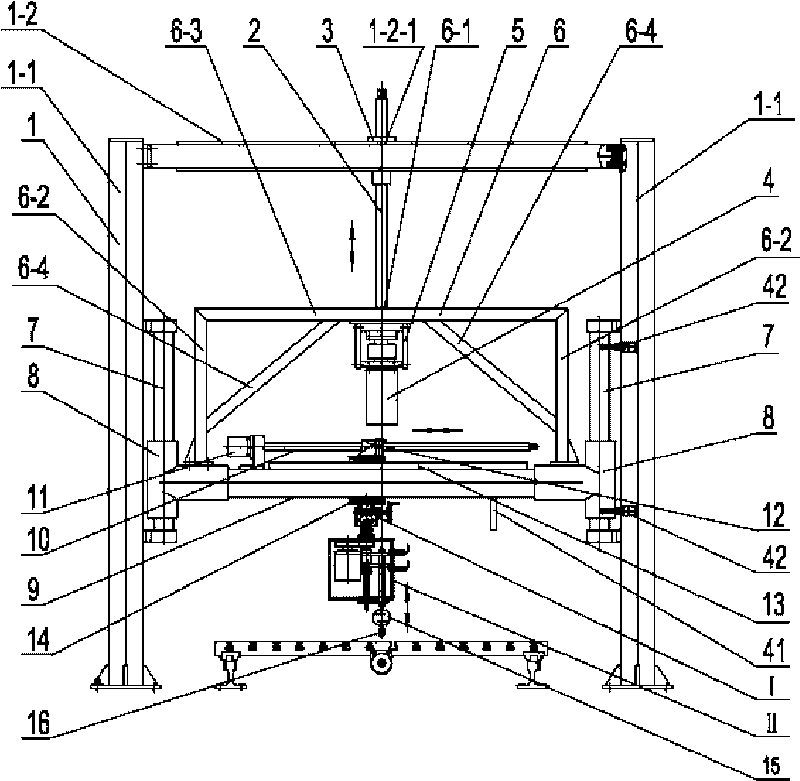

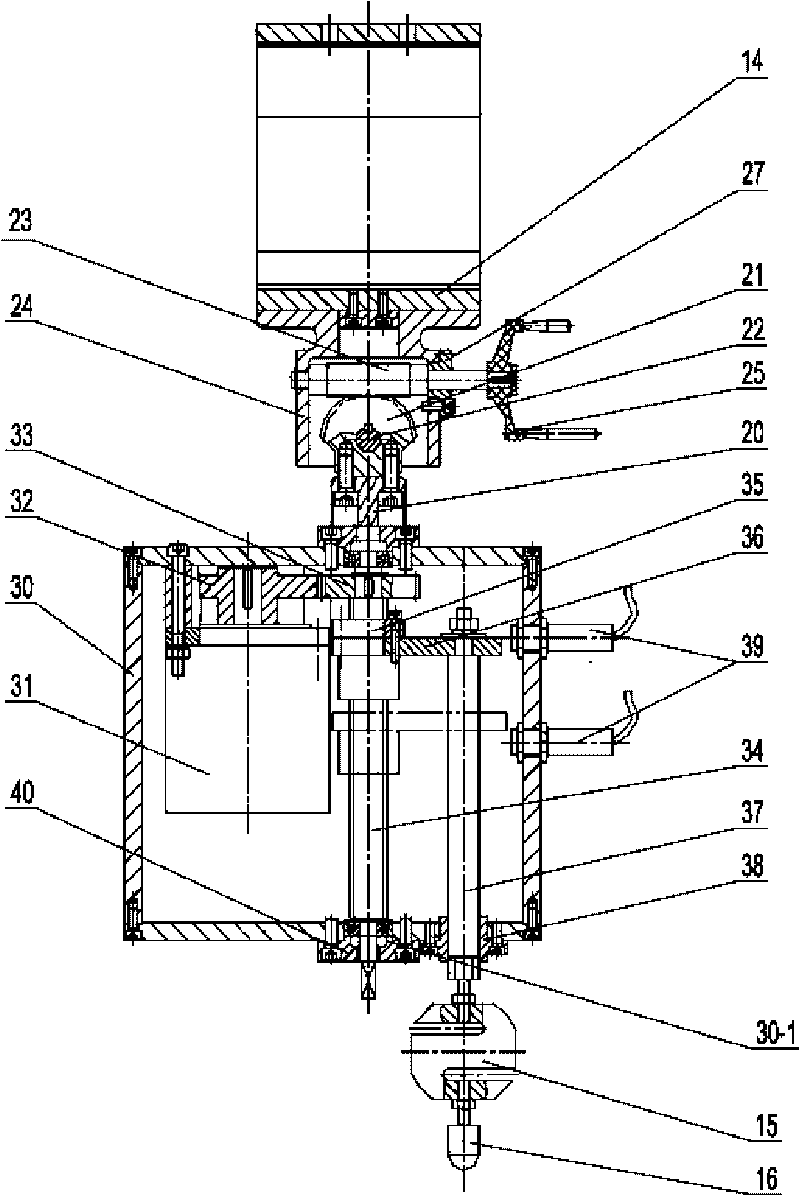

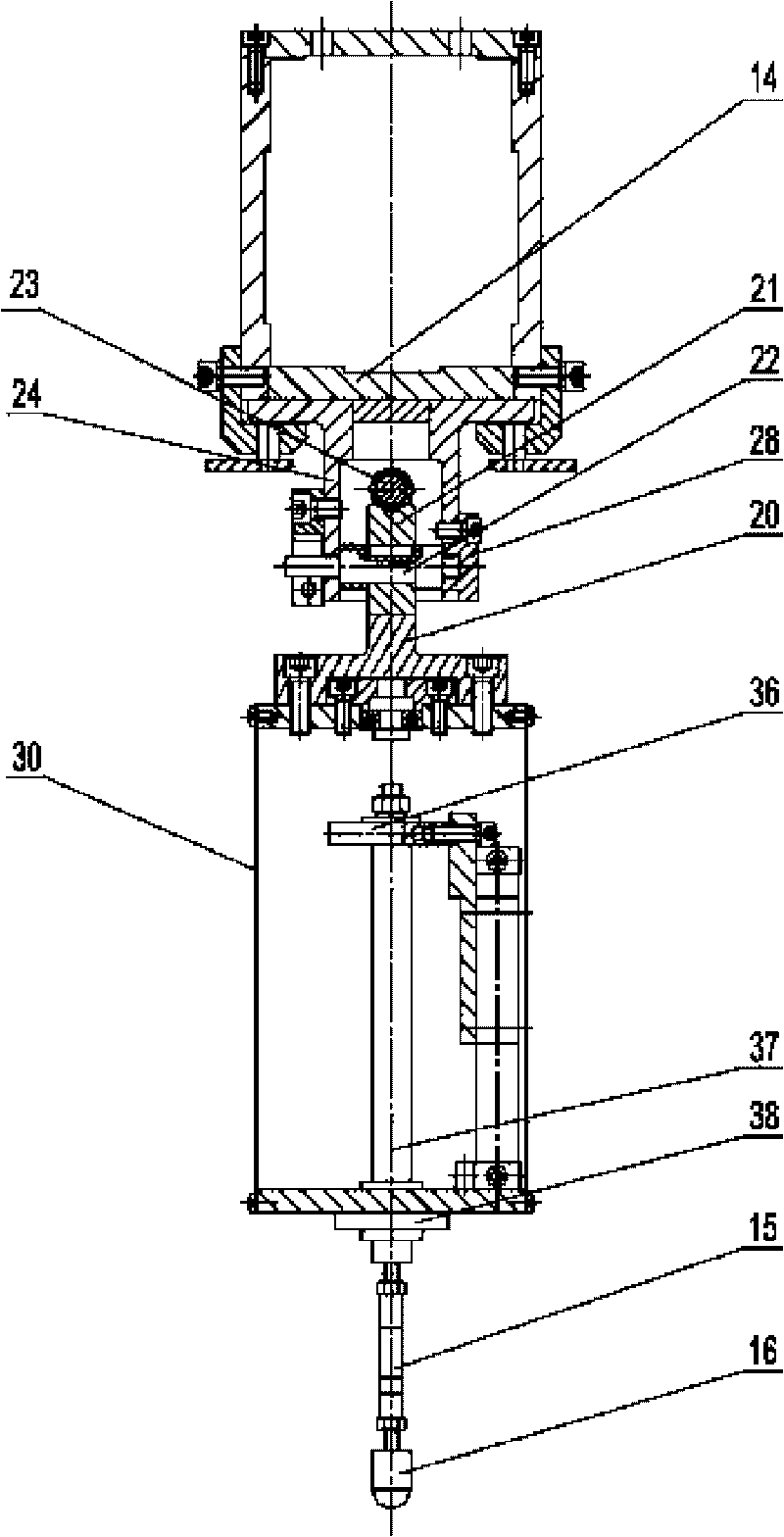

[0007] Specific implementation mode one: as Figure 1~3 As shown, the fixed sheet metal stamping parts rigidity testing device in this embodiment includes a frame 1, a first lead screw 2, a first screw nut 3, a first motor 4, a motor seat 5, a bracket 6, and two guide posts 7 , two tee sleeves 8, beam tube 9, second lead screw 10, second motor 11, second nut 12, guide rail 13, support slide 14, worm gear mechanism I, fine-tuning loading mechanism assembly II, A pressure sensor 15 and a pressure head 16, a first through hole 1-2-1 is opened on the beam 1-2 of the frame 1, and the first thread nut 3 is arranged in the first through hole 1 of the beam 1-2 - In 2-1, the upper part of the first lead screw 2 is screwed to the first screw nut 3, and the lower end of the first lead screw 2 passes through the second through hole 6-1 of the bracket 6 and connects with the first motor 4 The output shaft of the frame 1 is affixed, and the upper part of the bracket 6 is affixed to the fir...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 As shown, the rack 1 in this embodiment is composed of two columns 1-1 and a beam 1-2, and the upper ends of the two columns 1-1 are connected together by the beam 1-2. With such a design, the frame 1 has a simple structure, high rigidity and good stability. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 As shown, the bracket 6 in this embodiment is composed of two pillars 6-2, a horizontal frame 6-3 and two reinforcing ribs 6-4, and the upper ends of the two pillars 6-2 are connected by a horizontal frame 6-3 Together, one end of each reinforcing rib 6-4 is fixed on the horizontal frame 6-3, and the other end of each reinforcing rib 6-4 is fixed on the corresponding pillar 6-2, and the horizontal frame 6-3 The middle part has the second through hole 6-1. With such a design, the support 6 has a large bearing capacity, good rigidity, and negligibly small deformation during loading. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com