Automatic optical detection equipment

An optical automatic detection and equipment technology, which is applied in the direction of optical testing defects/defects, can solve the problems of unstable finished product quality, finished product defects, waste of manpower, etc., and achieve the effects of improving imaging clarity, stable outgoing light, and reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

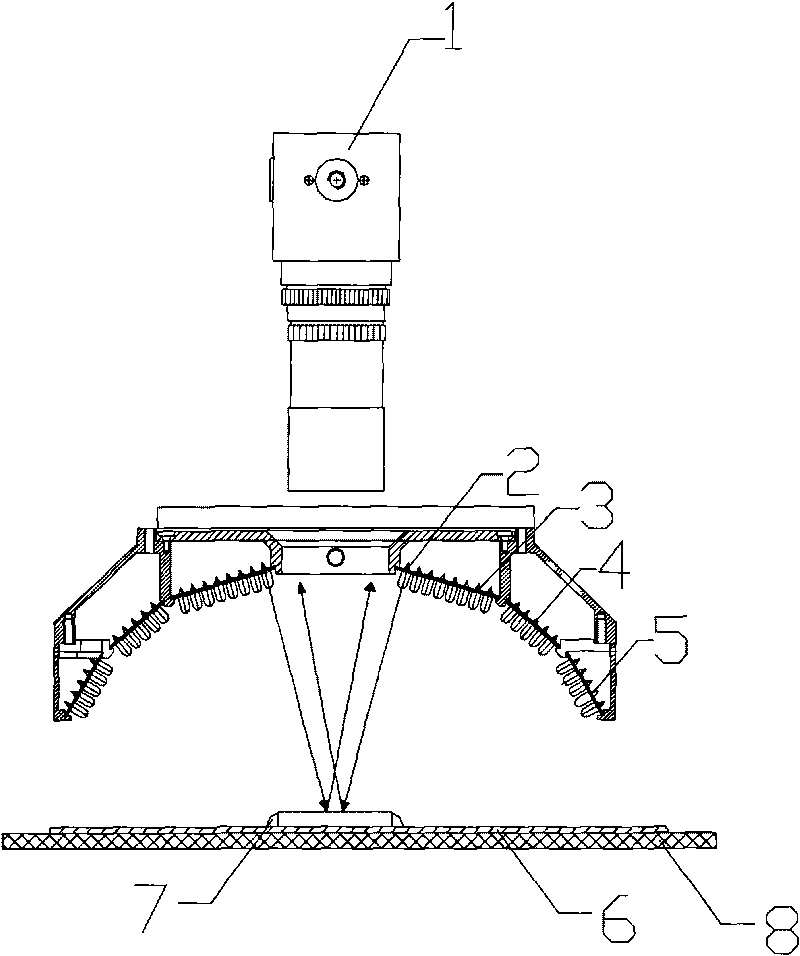

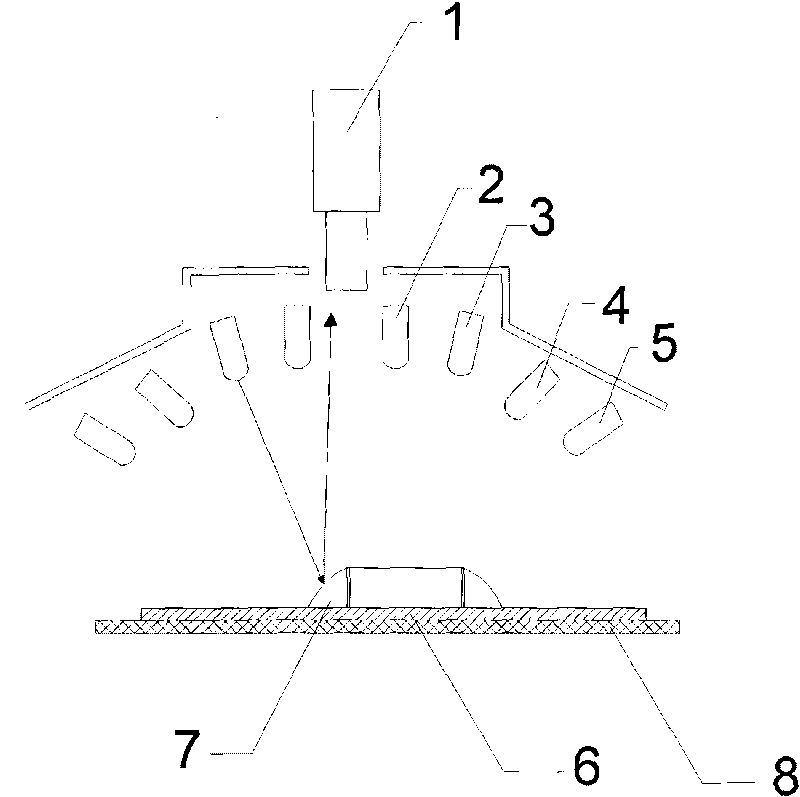

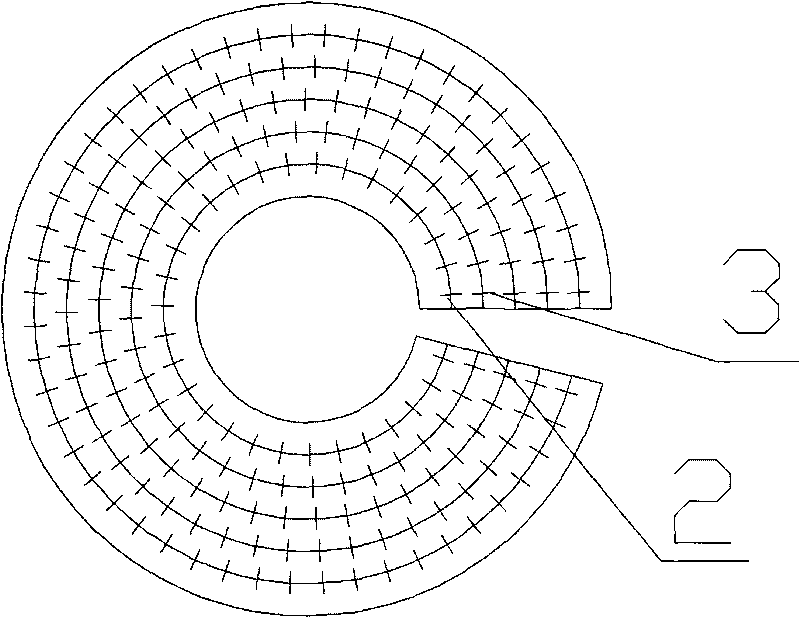

[0017] as attached figure 1 As shown, an optical automatic inspection device is used for soldering detection, which includes a camera 1, a light source surrounding the camera 1, a bearing platform 8 located below the camera 1 and the light source, a computer for image comparison, and the bearing platform 8 also includes an automatic transmission device for automatically conveying the detected items. The light source is 4 ring light sources, which are composed of light-emitting diodes of various colors. The white ring light source 2, the red ring light source 3, the green ring light source 4, and the blue ring light source 5 are arranged in sequence. After the axes of each ring light source coincide, you only need to adjust the angle of each ring light source to make each ring light source project To the same position and overlap, it is convenient to detect the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com