Jack-up drilling rig manufacturing tooling and manufacturing method

A self-elevating and drilling platform technology, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of long production cycle, low work efficiency, high production cost, etc., to reduce production cost, high production work efficiency, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

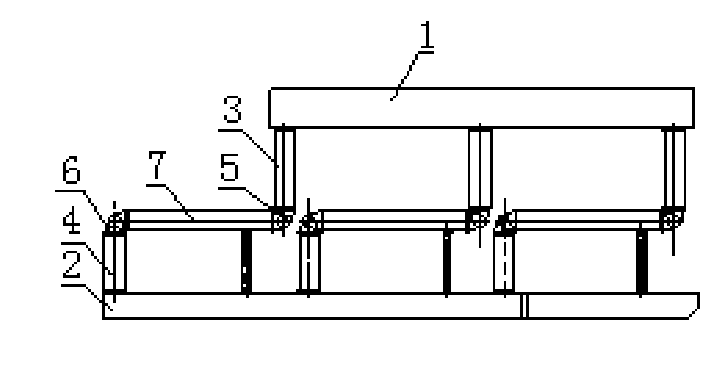

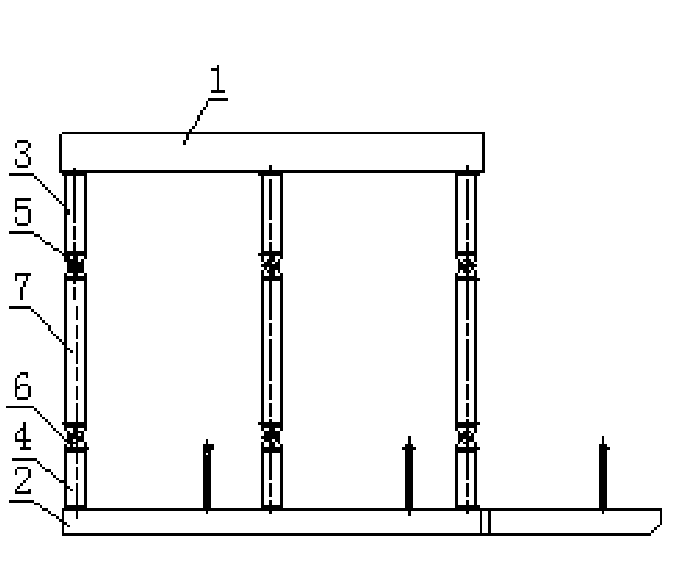

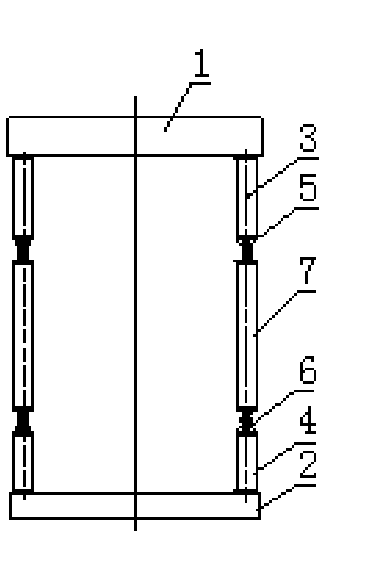

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as Figure 7 , Figure 8 As shown, the jack-up drilling platform manufacturing tooling of the present invention has a platform body 9, and the bottom surface of the platform body 9 is welded into three rows and two rows according to the welding position size of the six upper columns of the jack-up drilling platform on the platform. The arranged lugs 10, the platform body 9 table has a reference horizontal plane A processed by machine tools, in order to meet the parallelism between the centerlines of the connecting holes of three lugs 10 in each row, and the centerline of the connecting holes of two lugs 10 in each column Coaxiality, the technical requirements of the horizontal plane where the center line of the connecting hole of each ear seat 10 is parallel to the reference horizontal plane A, the platform body 9 that has been welded with six ear seats 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com