Sealing packing for steam chamber of tire vulcanizer and method for producing same

A tire vulcanization and production method technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of application limitation of vulcanizer sealing packing, affecting the stability of the vulcanization process, and being easily repelled by heat and pressure. Tire vulcanization process, the effect of preventing aging cracks and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to overcome the above-mentioned problems in the prior art, the present invention provides a sealing packing for the steam chamber of a tire vulcanizing machine and a production method thereof. Next, the sealing packing and its production method will be described in detail.

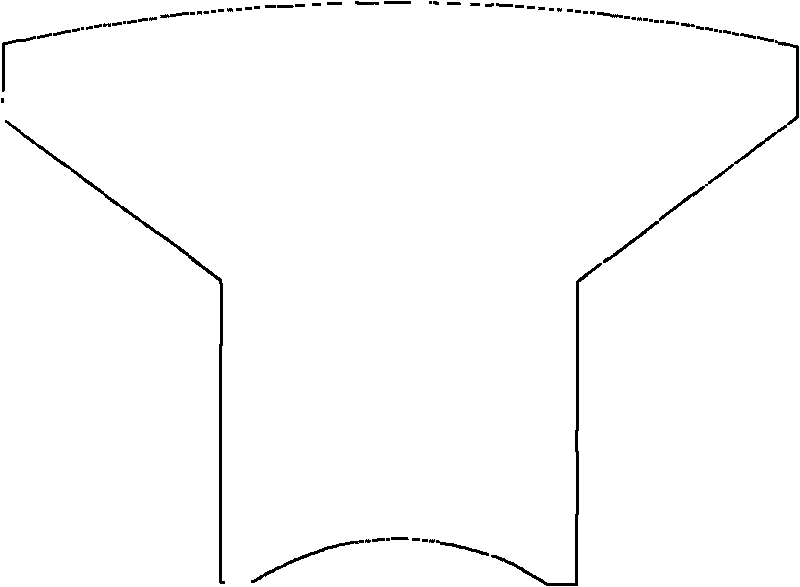

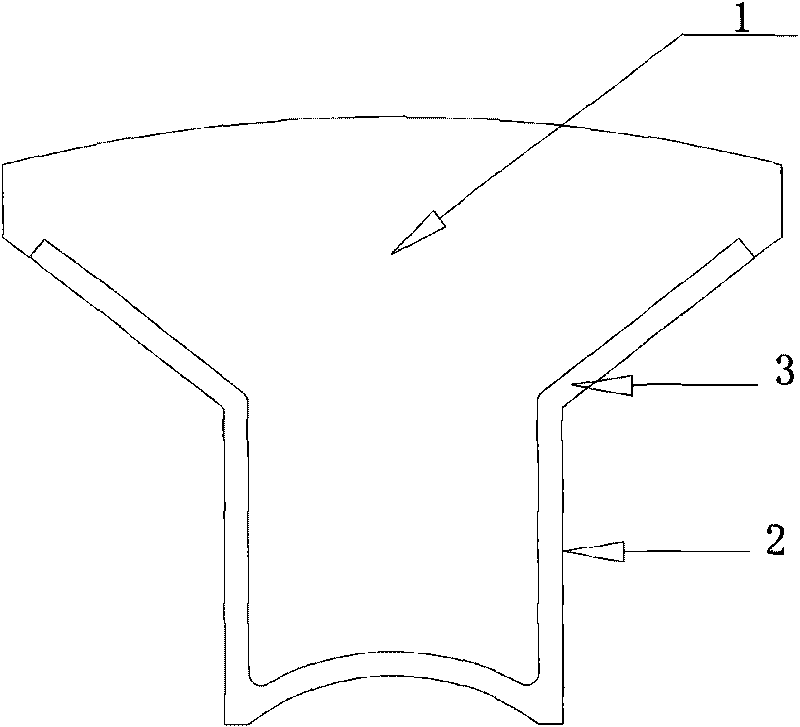

[0033] figure 2 Show the sectional structure diagram of the sealing packing root of the present invention, as figure 2 As shown, the sealing packing includes a main body core type 1 made of compounded rubber.

[0034] It also includes a fiber ply reinforcement layer 3 arranged on the main body core type 1, and the fiber reinforcement layer is applied on the outer surface 2 of the main body core type which is in contact with the lower half mold of the steam chamber.

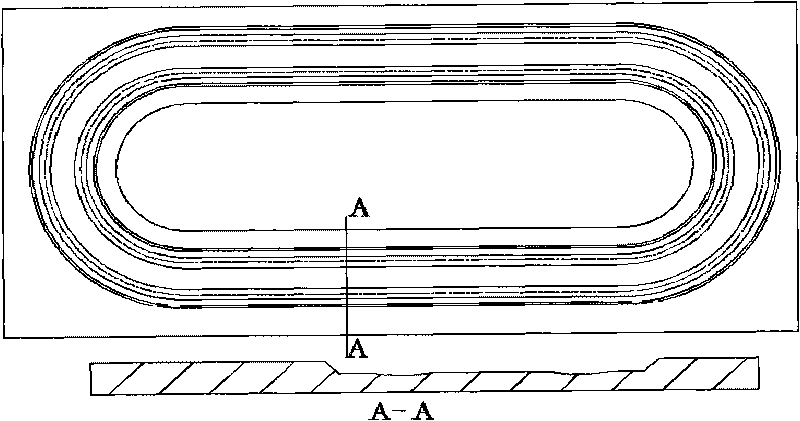

[0035] The sealing packing mentioned above is in the shape of a ring. In comparison, the ring shape has no cutout and end plug contact, so the seal is good.

[0036] The height at which the fiber reinforced layer 3 is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com