Tempering adjusting device of thin-walled cylinder body

A technology of thin-walled cylinder and shape correction, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of high labor intensity, cumbersome process, and affecting production efficiency, and achieve convenient operation, high precision, and simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

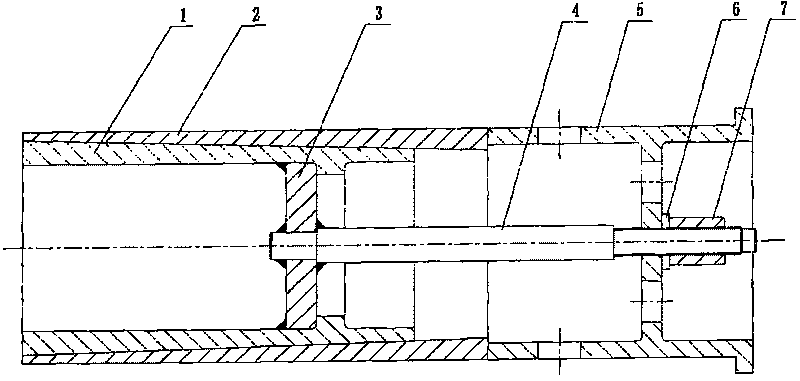

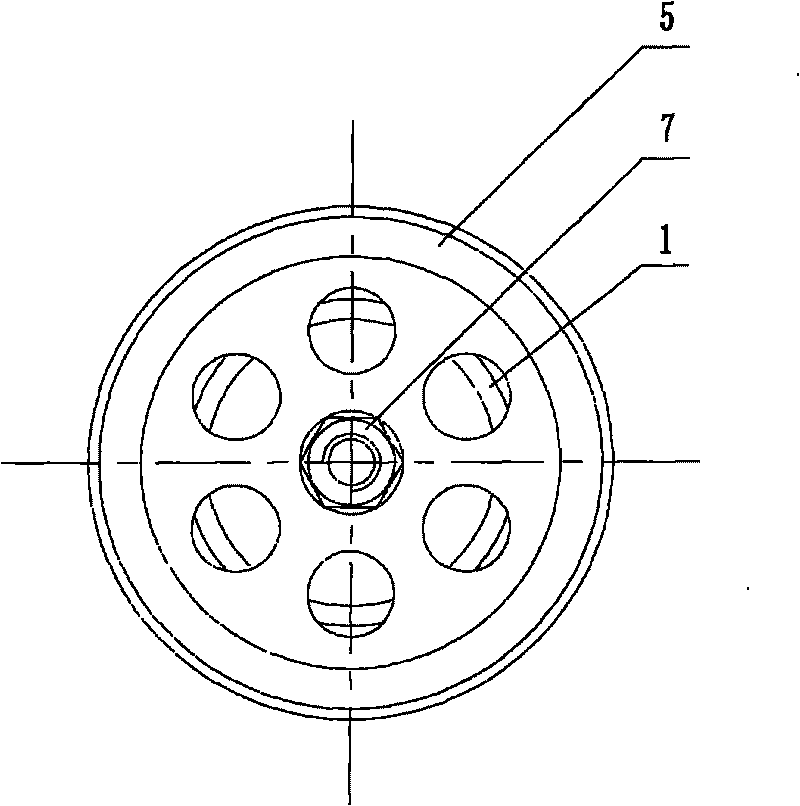

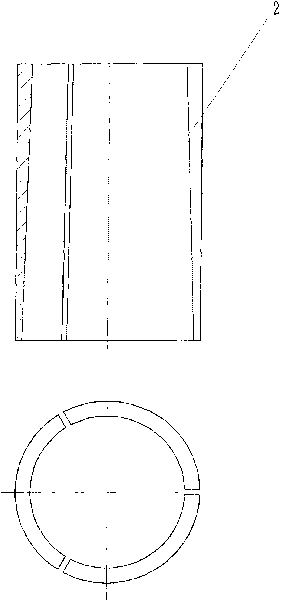

[0012] A thin-walled cylindrical body tempering correction device, which includes a cone 1, a movable block 2, a pull plate 3, a screw rod 4, a retaining ring 5, a washer 6, a large nut 7, and the pull plate 3 is welded to the cone 1 At the stop of the inner cavity, one end of the screw 4 is welded to the center hole of the pull plate 3, the cone 1, the pull plate 3, and the screw 4 are welded to form a whole, and the movable expansion block 2 is a third or multi-equal cone Petal block structure, the cone angle of cone 1 is 5-7°, the cone angle of the outer surface of cone 1 is consistent with the cone angle of the inner surface of movable block 2, the outer cone surface of cone 1 is the same as that of movable block 2 The inner cones match, the end face of the movable expansion block 2 with the smaller diameter is close to the stop of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com