Turnover device

A technology of loading cavity and side plate, which is applied in packaging, transportation and packaging, and packaging of vulnerable items, can solve the problems of the substrate 50` yield drop, substrate 50` scratches, substrate 50` pollution, etc., and achieve cleanliness The effect of reducing the concentration of internal stress and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

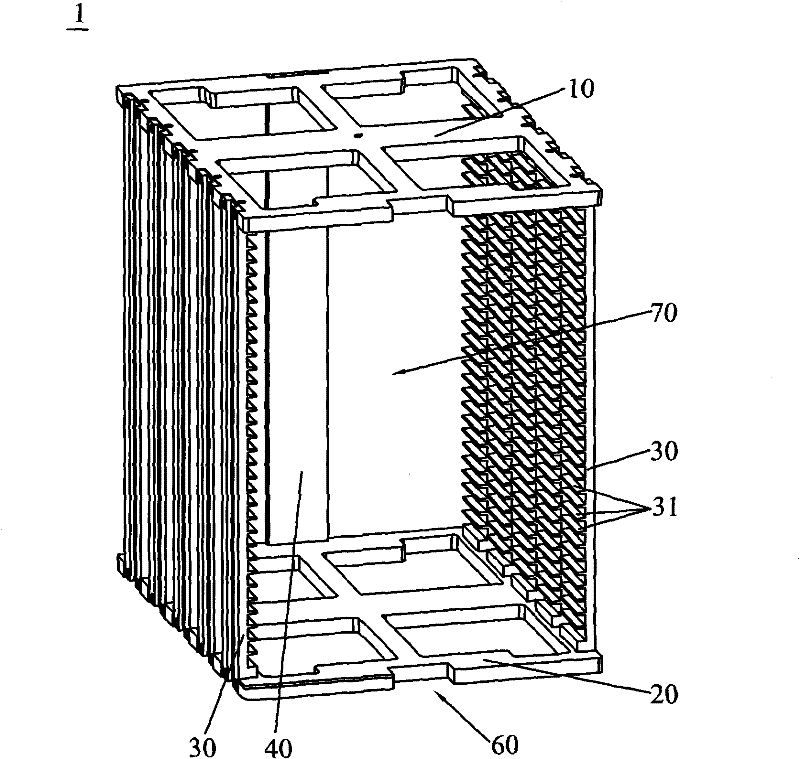

[0032]Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

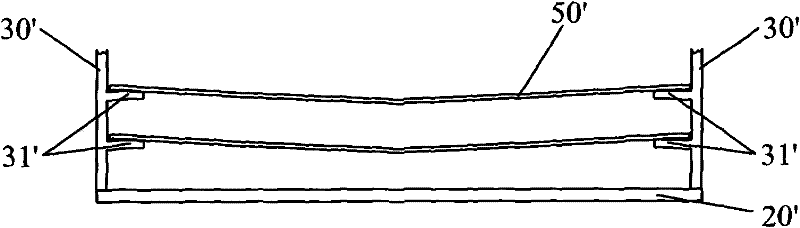

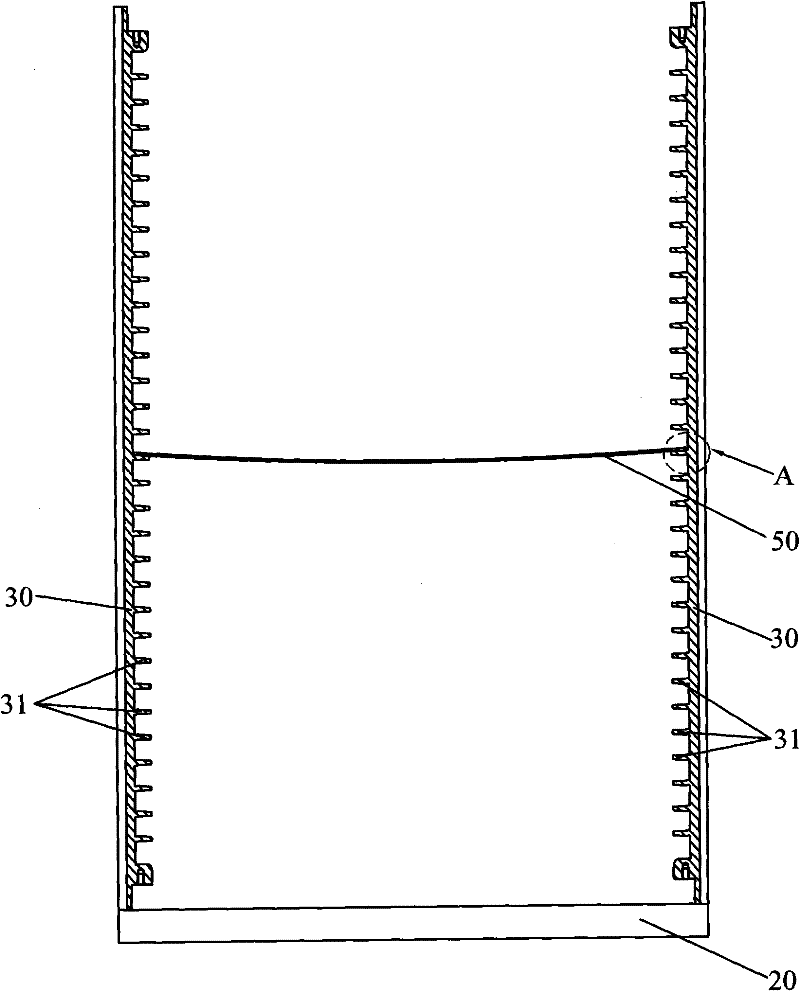

[0033] like Figure 2-Figure 5 As shown, the turnaround device 1 of the present invention is used to carry and transport thin-plate-shaped substrates 50. It includes a top plate 10, a bottom plate 20, a baffle plate 40, and two side plates 30. The top plate 10 and the bottom plate 20 are arranged in parallel, and the two side plates 30 They are arranged parallel to each other between the top plate 10 and the bottom plate 20, the side plates 30 are perpendicular to the top plate 10 and the bottom plate 20, the top plate 10, the bottom plate 20 and the side plates 30 form a substrate loading chamber 70 with two openings, and the baffle plate 40 is arranged on Between the top plate 10 and the bottom plate 20, and the baffle plate 40 is located at one of the two openings and is perpendicular to the two side plates 30, the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com