Method for supporting steel grating

A technology of steel grid and steel wire mesh, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., and can solve the problem of insufficient overall strength of anchor rods and steel wire mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

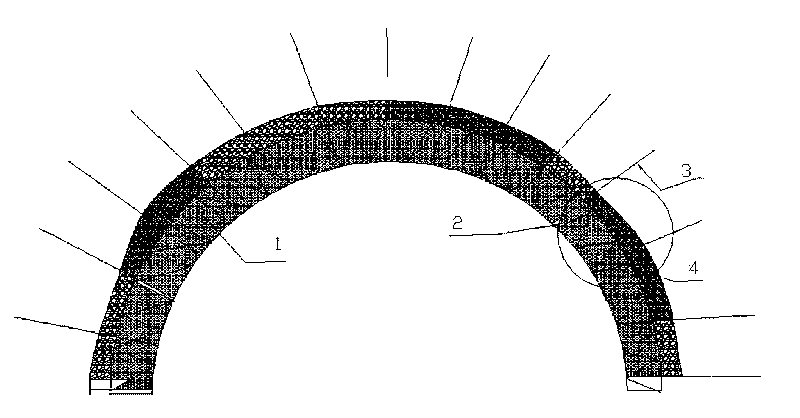

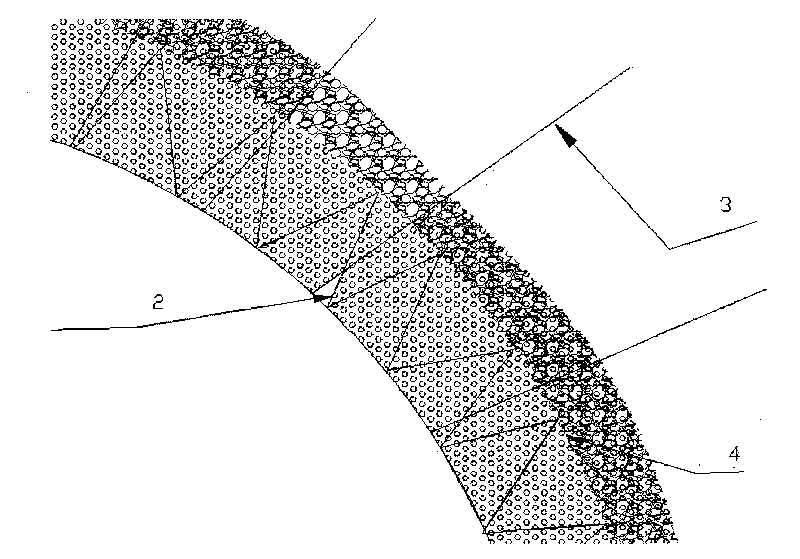

[0015] When excavating roadways and large chambers, such as crushing chambers, water pump rooms, central substations, etc., if you encounter general broken zones (surrounding rocks are broken but can be stable for a period of time) and faults, support measures are required. To ensure the construction safety in the broken zone area. Below, the steel grid support method involved in the present invention will be described in detail in conjunction with the drawings and specific embodiments.

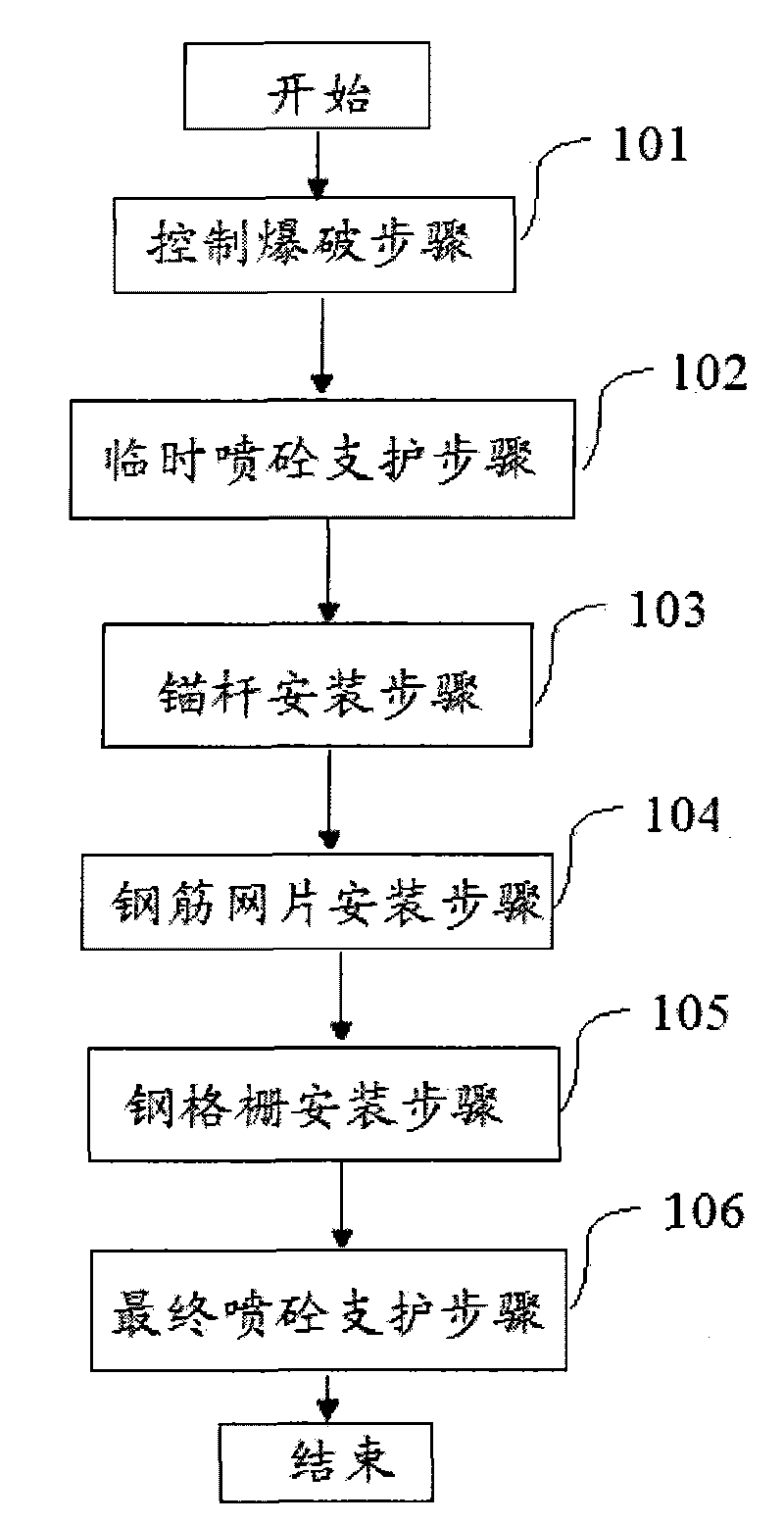

[0016] figure 1 It is a flow chart representing the steel grid support method involved in the present invention. Here, refer to figure 1 Describe in detail the steps of the steel grid support method.

[0017] First, step 101 of controlled blasting is performed. That is, when excavating a large chamber, due to the release of the surrounding rock stress and the impact of previous blasting vibration and other factors, accidents such as collapse are very easy to occur near the broken zone or f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com