Shift hydraulic control circuit of dual-clutch gearbox

A clutch control, dual clutch technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of complicated shift control scheme, inability to adapt to small cars, difficult design and manufacture of valve blocks, etc. , to achieve the effect of simplifying the shifting hydraulic control system of the dual-clutch transmission, easy design and manufacture, and reducing the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

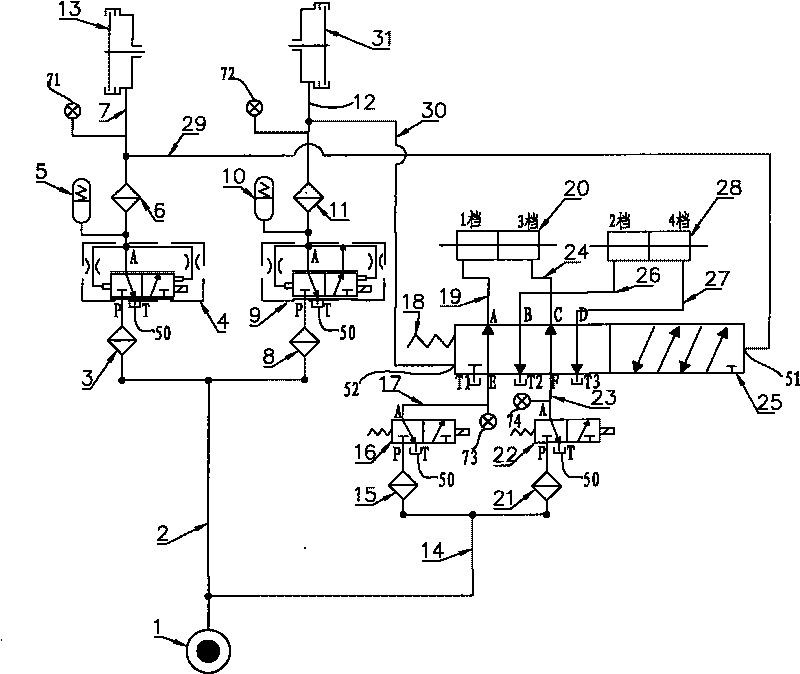

[0019] Such as figure 1 As shown, the first embodiment of the hydraulic control circuit for shifting of the dual-clutch gearbox of the present invention includes a clutch pressure control circuit for controlling the action of the dual clutch, two two-position three-way solenoid valves 16, 22 for shifting and one shifting The shift hydraulic circuit that controls the action of the shift oil cylinder is composed of the multi-way valve 25, and the shift multi-way valve 25 is controlled by the pressure control device to make it actuate.

[0020] In the clutch pressure control circuit, the dual clutches are odd clutches 13 and even clutches 31. One end of the clutch main oil passage 2 is connected to the main oil source 1, and the other end is connected to the first filter 3 and the second filter 8 respectively. The outlet of the filter 3 is connected with the oil supply port P of the two-position three-way solenoid valve 4 of the odd clutch through the pipeline, and the oil return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com