Horizontal shell and tube type condenser with liquid guide devices

A shell-and-tube condenser technology that is applied to steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc. Problems such as the increase in the volume of thermal equipment, to achieve the effect of reducing the thickness of the liquid film, simple installation, and avoiding the increase of the thickness of the liquid film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

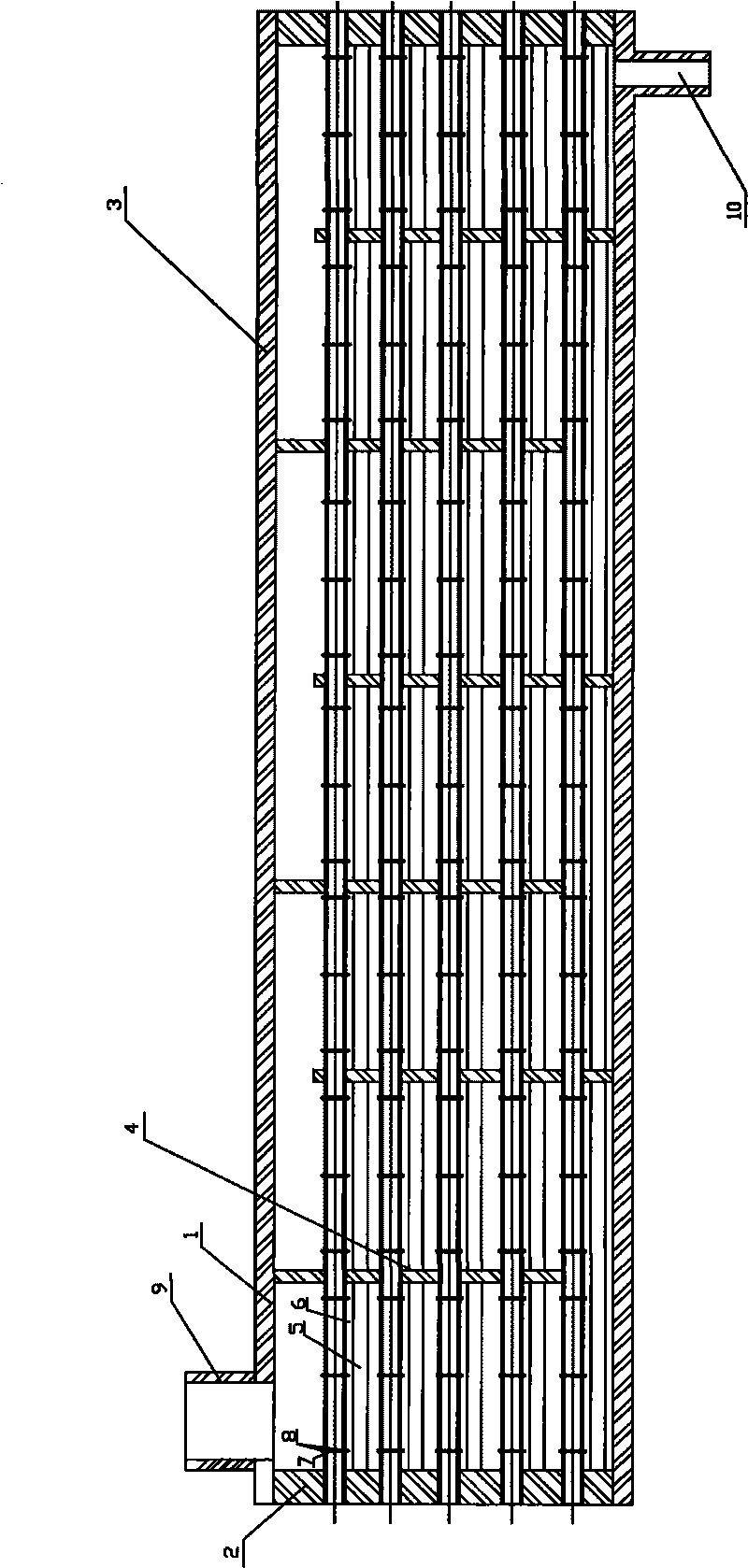

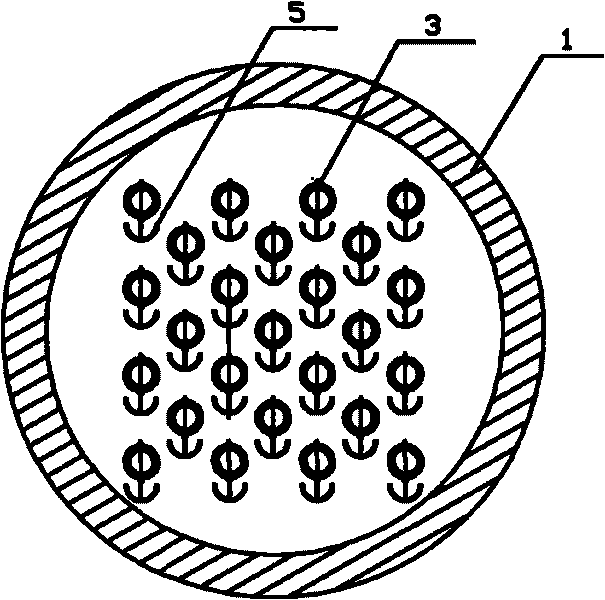

[0042] A horizontal shell-and-tube condenser with a liquid guide, its composition includes: a shell 1, the two sides of the shell are connected to the tube plate 2, and the shell space enclosed by the shell and the tube plate A set of heat exchange tubes 3 are installed, the heat exchange tubes are equipped with a support plate 4, a continuous liquid guide 5 is installed under the heat exchange tubes, and an air inlet 9 and an outlet are opened on the shell. Liquid port 10.

Embodiment 2

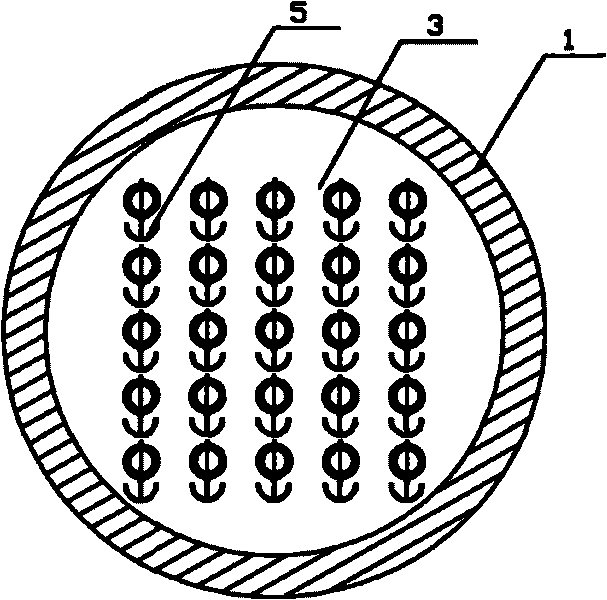

[0044] A horizontal shell-and-tube condenser with a liquid guide, its composition includes: a shell 1, the two sides of the shell are connected to the tube plate 2, and the shell space enclosed by the shell and the tube plate A set of heat exchange tubes 3 are installed, the heat exchange tubes are equipped with a support plate 4, a continuous liquid guide 5 is installed under the heat exchange tubes, and an air inlet 9 and an outlet are opened on the shell. Liquid port 10.

[0045] In the horizontal shell-and-tube condenser with a liquid guide, a continuous flow guide plate 6 is included between the heat exchange tube and the liquid guide.

Embodiment 3

[0047] A horizontal shell-and-tube condenser with a liquid guide, its composition includes: a shell 1, the two sides of the shell are connected to the tube plate 2, and the shell space enclosed by the shell and the tube plate A set of heat exchange tubes 3 are installed, the heat exchange tubes are equipped with a support plate 4, a continuous liquid guide 5 is installed under the heat exchange tubes, and an air inlet 9 and an outlet are opened on the shell. Liquid port 10.

[0048] In the horizontal shell-and-tube condenser with a liquid guide, a continuous flow guide plate 6 is included between the heat exchange tube and the liquid guide.

[0049] The horizontal shell-and-tube condenser with a liquid guide, the liquid guide is a liquid collection type liquid guide, its section shape is a single arc, and the liquid guide is along the length of the heat exchange tube The direction has a bump towards one end.

[0050] In the horizontal shell-and-tube condenser with a liquid g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com