Rotor and self-starting three-phase permanent magnet motor

A permanent magnet motor, self-starting technology, applied in the field of electric motors, can solve the problems of large overall size of the motor, inability to meet, inability to meet large starting torque and pull-in torque, etc., and achieves compact structure, increased practicability, and overall size. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the self-starting three-phase permanent magnet motor of the present invention will be described in detail below with reference to the accompanying drawings and in conjunction with exemplary embodiments.

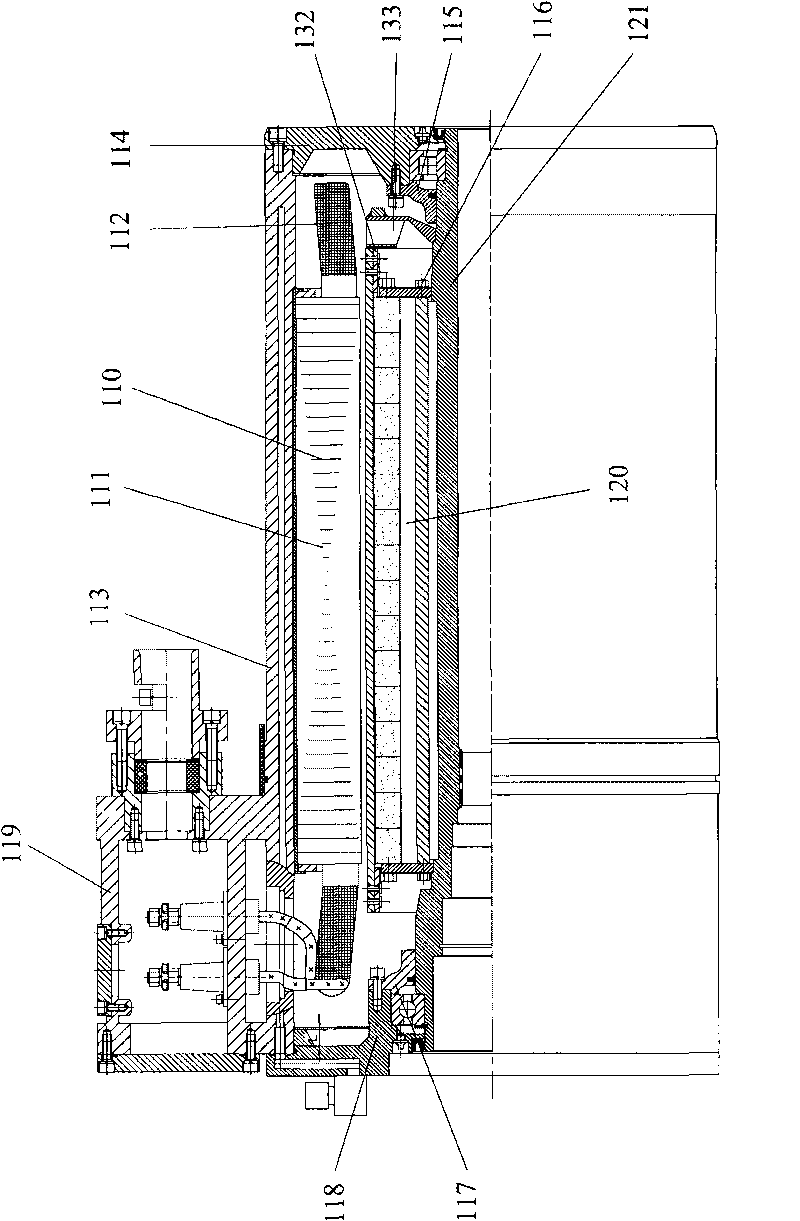

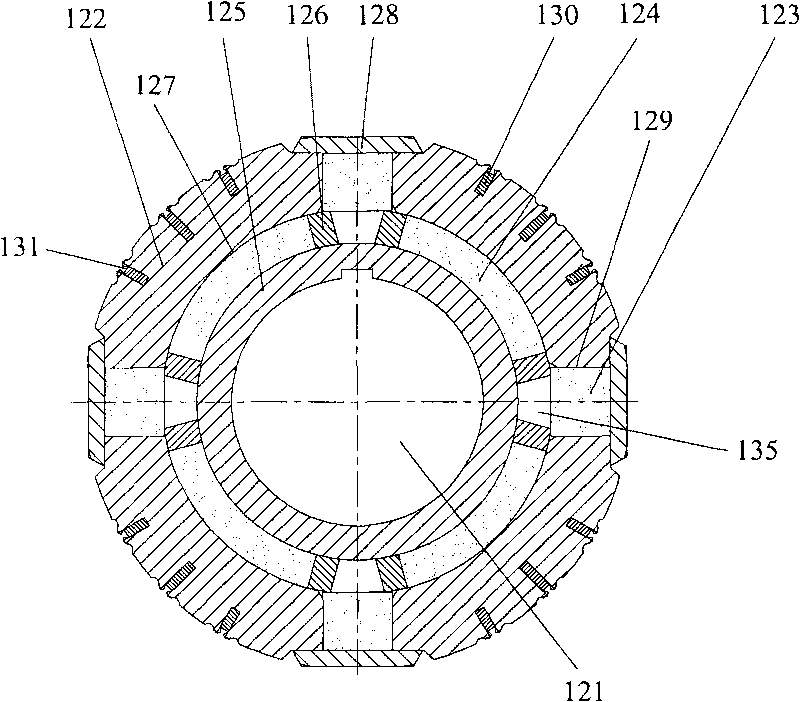

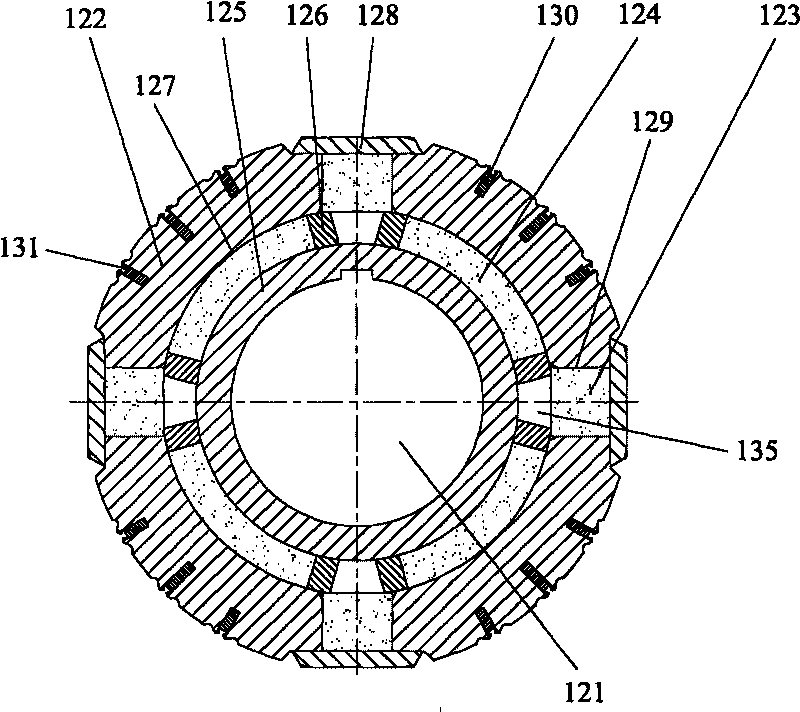

[0020] figure 1 shows an assembly half-sectional view of a self-starting three-phase permanent magnet motor 100 according to the present invention, figure 2 A cross-sectional view of the rotor 120 therein is shown. As shown in the figure, the self-starting three-phase permanent magnet motor 100 according to the present invention includes a stator part 110 and a rotor 120 installed in the stator 110, and the stator 110 includes a stator core 111 and a stator winding wound outside the stator core 111 112. The stator 110 also includes a front end cover 115, a front inner cover 115, an end plate 116, a rear inner cover 117, a rear end cover 118 and a junction box 119, the above components are used to securely install the stator 110 and the rotor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com