Method and system for producing LNG

A fractionation tower and feed gas technology, applied in the field of LNG production and systems, can solve problems such as unintegrated fractionation towers

Active Publication Date: 2010-05-19

阿拉贡股份有限公司

View PDF20 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the setup in the EP patent does not integrate the fractionation column and downstream LNG condensation process which is the object of the present invention

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0071] In the following example a natural gas with 90.4% methane by volume is shown to be liquefied, where the invention is used to maximize the amount of liquefied gas while minimizing Unstable hydrocarbon liquid by-product. Logistics data reference figure 1 , 2 , 3, 4 or 5.

[0072] tracking number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

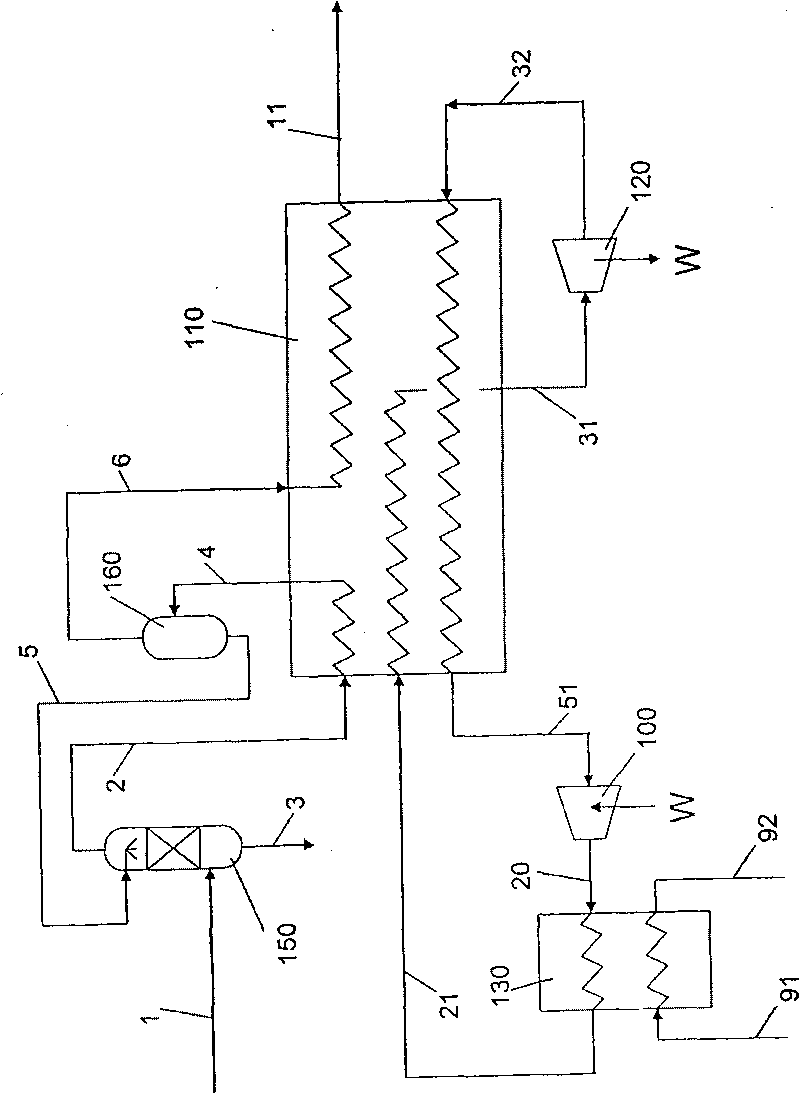

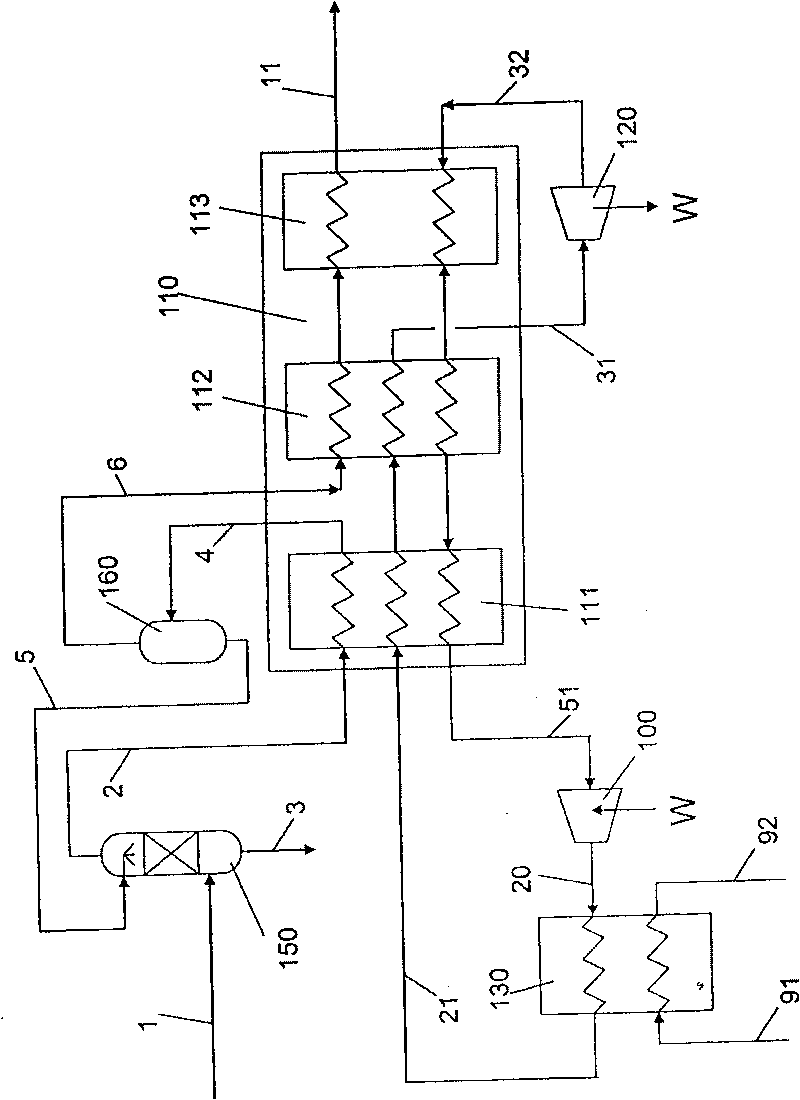

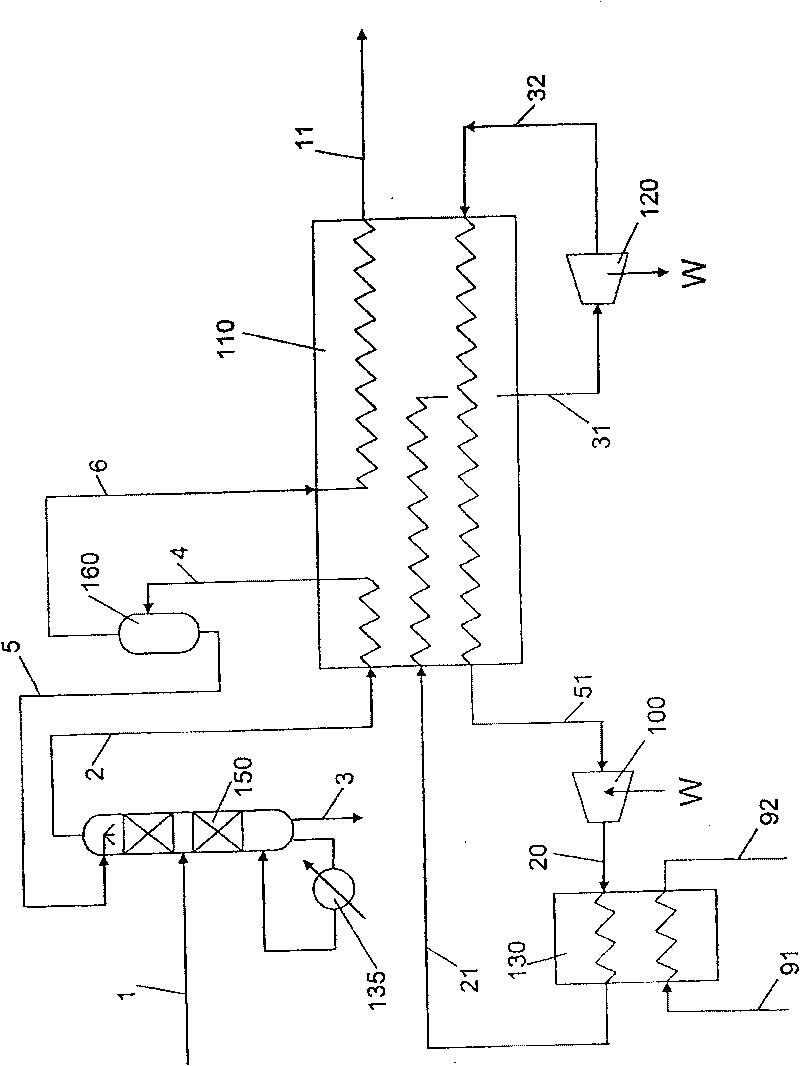

A method is described for production of LNG from an incoming feed gas (1 ) on an onshore or offshore installation, and it is characterised by the following steps: 1 ) the feed gas is led through a fractionation column (150) where it is cooled and separated in an overhead fraction with a reduced content of pentane (C5) and heavier components, and a bottom fraction enriched with heavier hydrocarbons, 2) the overhead fraction from the fractionation column is fed to a heat exchanger system (110) and is subjected to a partial condensation to form a two-phase fluid, and the two-phase fluid is separated in a suitable separator (160) into a liquid (5) rich in LPG and pentane (C3-C5) which is re-circulated as cold reflux to the fractionation column (150), while the gas (6) containing lower amounts of C5 hydrocarbons and hydrocarbons heavier than C5 is exported for further processing in the heat exchanger system (110) for liquefaction to LNG with a maximum content of ethane and LPG 3) the cooling circuit for liquefaction of gas in the heat exchanger system comprises an open or closed gas expansion process with at least one gas expansion step. A system for carrying out the method is also described.

Description

technical field [0001] As can be seen from the preamble of independent claim 1, the present invention relates to a method for optimally producing LNG on a fixed or floating offshore installation. [0002] The invention also relates to a system for carrying out the process, comprising a fractionation column for feeding feed gas, a heat exchanger system for cooling and partially condensing the overhead gas stream of the fractionation column, for separating separator for the two-phase stream of the separator system, means for returning the liquid from the separator to the fractionation column and feeding this liquid as reflux to the upper part of the column, and for returning the gas from the separator to the heat exchanger system A device for further cooling and liquefaction into LNG. Contents of the invention [0003] The present invention contemplates the use of a closed gas expansion process to liquefy natural gas, and wherein the gas is first fed through a fractionation c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25J3/02F25J1/02

CPCF25J1/0092F25J2270/16F25J1/0097F25J1/0216F25J1/0037F25J1/0241F25J2210/06F25J1/0204F25J1/0087F25J2220/64F25J1/0278F25J1/0221F25J1/0057F25J1/0082F25J1/0202F25J1/005F25J2270/90F25J1/0205F25J2210/60F25J1/0052F25J1/0281F25J1/0215F25J1/0212F25J1/0232F25J1/0294F25J1/0201F25J1/0022F25J1/0072F25J1/0288F25J1/0238B01D3/14C10L3/08F25J1/02F25J3/02

Inventor 英格·斯威尔·伦德尼尔森

Owner 阿拉贡股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com