Spiral sludge dewatering equipment with collapsable shaft

A sludge dewatering machine and stacked screw technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of reducing the service life of movable plates, and achieve the effects of increasing service life, reducing pressure and improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

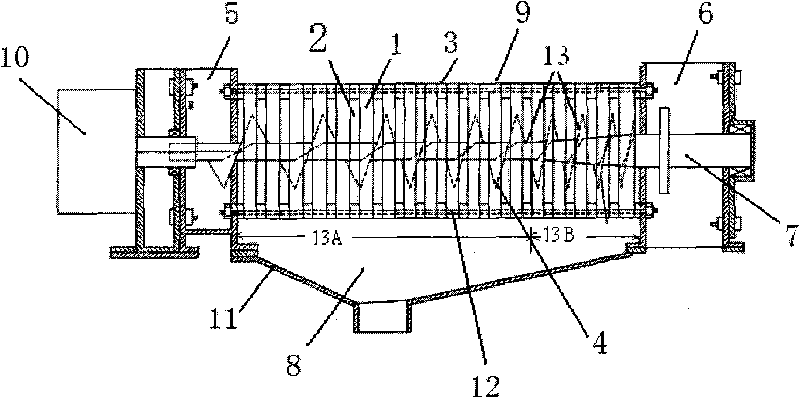

[0012] The screw stacking sludge dewatering machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

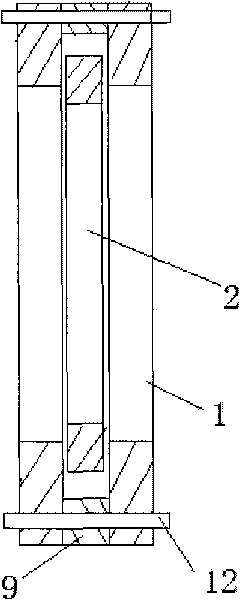

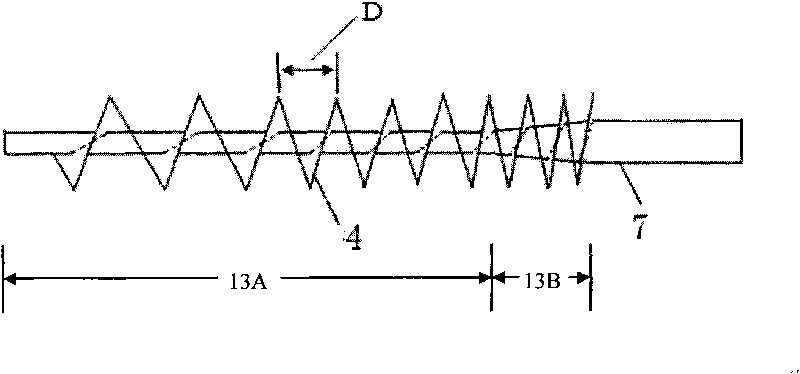

[0013] like figure 1 Shown is a schematic structural view of the screw stacking sludge dehydrator of the present invention, a screw stacking sludge dewatering machine using a variable diameter shaft, including a housing 11, a fixed plate 1, a movable plate 2 and a screw shaft 7 and a structure. The filter body 3, the filtrate recovery device 8, the mud feeding box 5 and the mud discharging box 6, several annular fixing plates 1 are arranged in sequence inside the shell 11, and a concentric and movable An annular movable plate 2, a filtrate recovery device 8 is provided at the bottom of the filter body 3; the screw shaft 7 runs through the interior of the fixed plate 1 and the movable plate 2, and the mud feeding box 5 and the mud discharging box 6 are respectively arranged at both ends of the screw shaft 7 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com