Adhesion and doodling prevention coating

An anti-graffiti and anti-sticking technology, applied in the field of architectural decorative coatings, can solve the problems of disappearance, anti-graffiti function reduction, urban environmental pollution, etc., and achieve good anti-graffiti, fast drying, and high cross-linking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

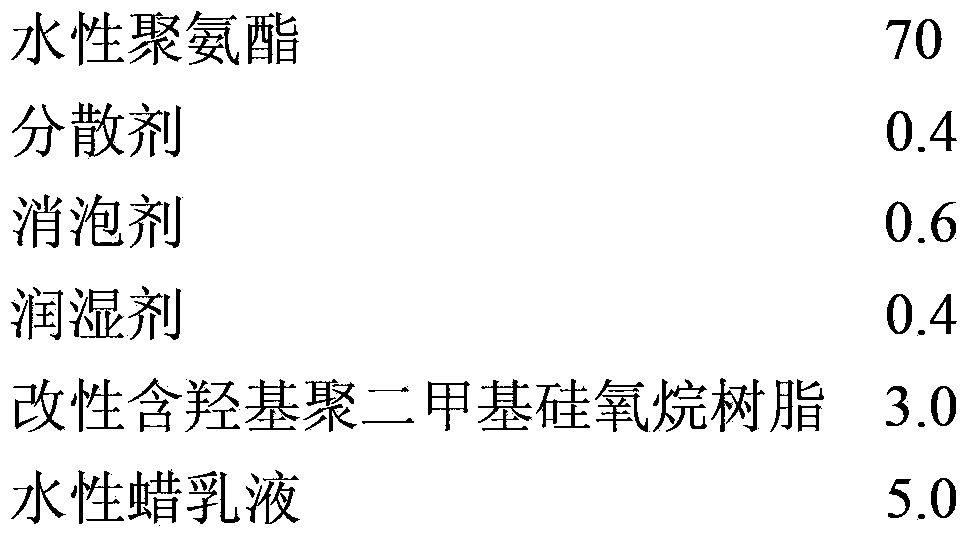

Embodiment 1

[0029] Firstly, the component A of the anti-blocking and anti-graffiti coating of the present invention is prepared.

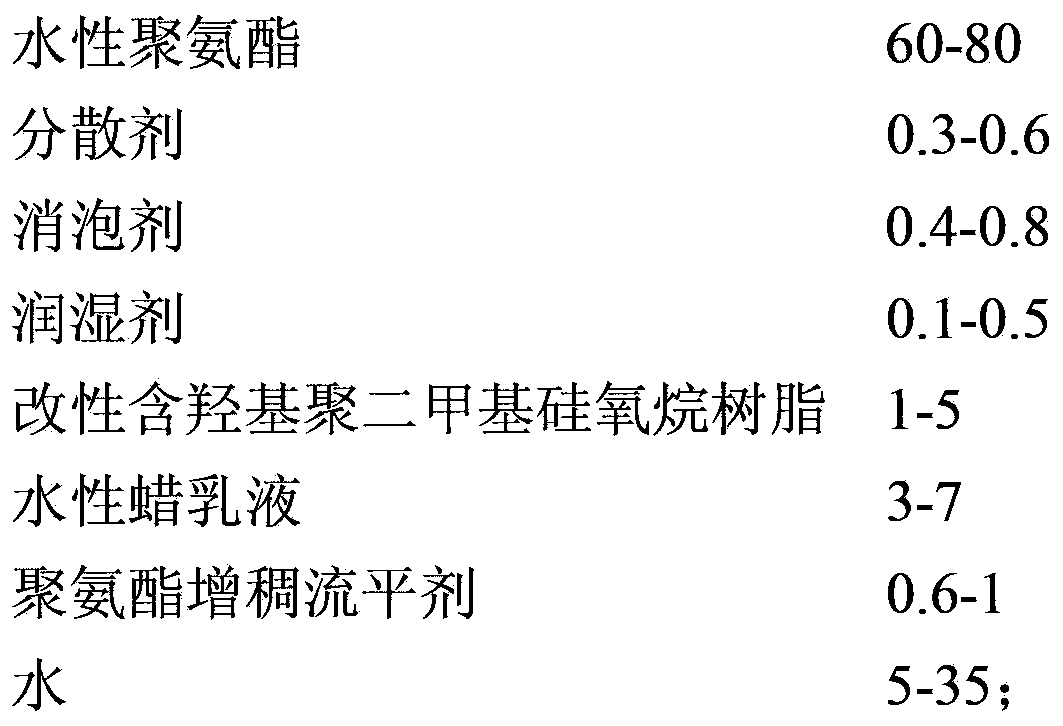

[0030] Get each component by the weight shown in embodiment 1 in table 1, and preparation method is according to the following steps:

[0031] Step 1: Add 60kg of AXP 2695 water-based polyurethane resin into the paint mixing container and stir at low to medium speed, and add 0.3kg of SN-5027 dispersant, 0.1kg of BYK346 wetting agent and 0.2kg of 901W defoamer (1) under stirring , polyurethane thickening and leveling agent 0.6kg, after adding, continue to stir at a medium speed for more than 3 minutes;

[0032] Step 2: Add 1.0 kg of TEGO5100 modified hydroxyl-containing polydimethylsiloxane resin into Step 1 under strong stirring, and continue to stir vigorously for more than 15 minutes after adding;

[0033] Step 3: Add 3.0kg of WE6 water-based wax emulsion, 0.2kg of defoamer (2), and 34.6kg of water under low to medium speed stirring; after adding, continue ...

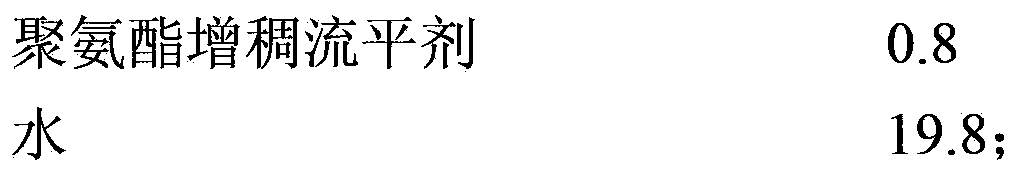

Embodiment 2

[0036] Get each component by the weight shown in Example 2 in Table 1. Repeat the preparation method described in Example 1 (only the weight of each component is different) to prepare the anti-sticking and anti-graffiti coating A component of Example 2. Take 100Kg of the prepared A component, mix it with 29.1Kg of B component (OH:NCO=1.8), and let it stand for more than 5 minutes. The performance testing results are shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0038]Get each component by the weight shown in embodiment 3 in table one. Repeat the preparation method described in Example 1 to prepare the anti-sticking and anti-graffiti coating A component of Example 3. Take 100Kg of the prepared A component, mix it with 35.13Kg of B component (OH:NCO=2.0), and let it stand for more than 5 minutes. The performance test results are shown in the corresponding data of Example 3 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com