Engine using glow plug resistance for estimating combustion temperature

A combustion temperature, glow plug technology, applied in engine ignition, engine control, engine components, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

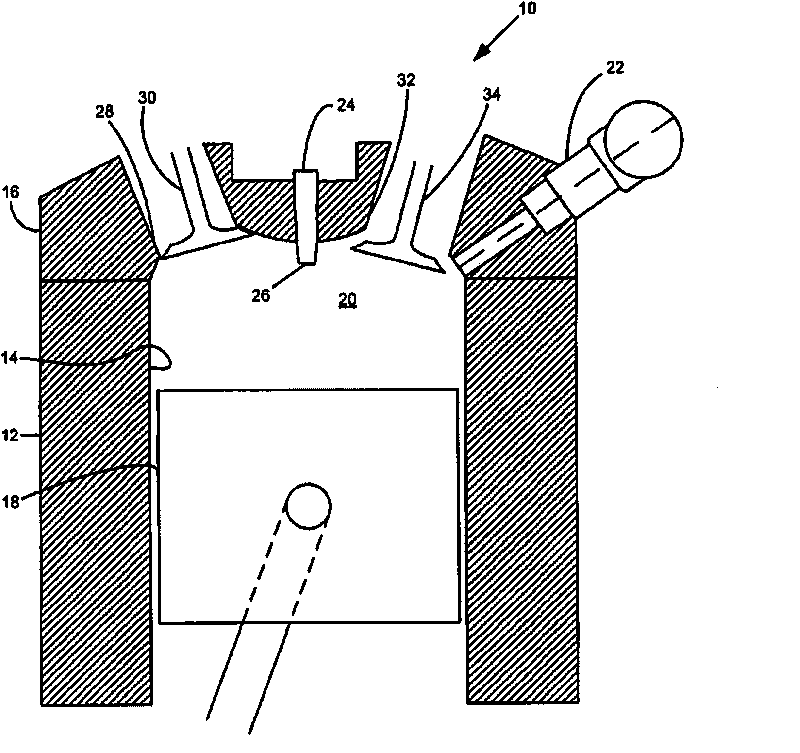

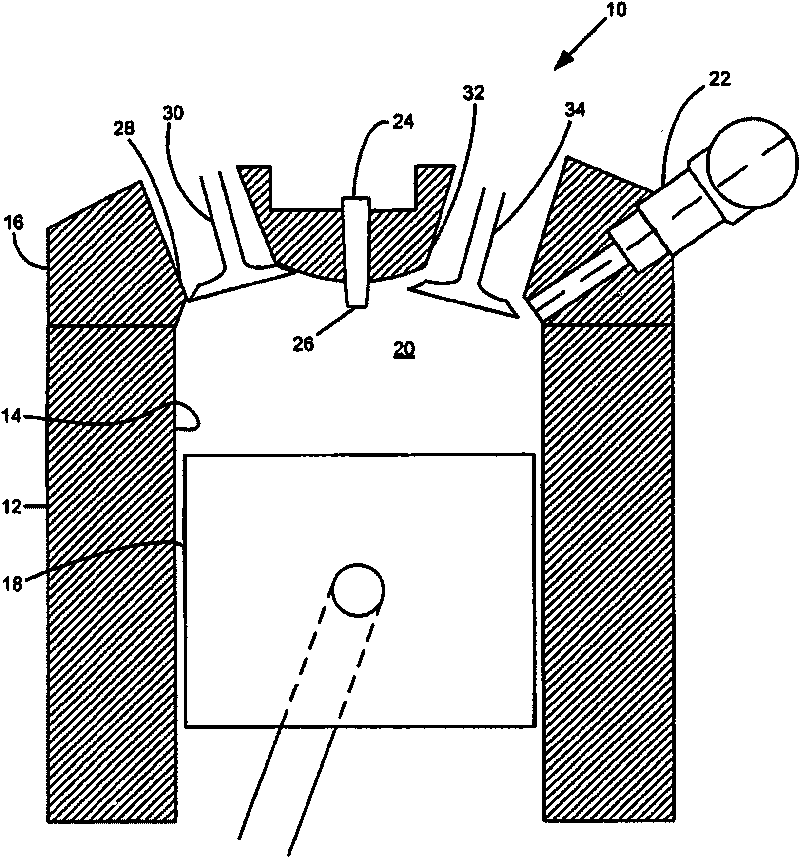

[0019] refer to figure 1 , showing an exemplary diesel engine with a glow plug disposed within the combustion chamber. Specifically, diesel engine 10 has a cylinder block 12 defining at least one cylinder 14 enclosed by a cylinder head 16 . It should be understood that a typical engine includes a plurality of cylinders 14 . Piston 18 reciprocates within cylinder 14 and, with cylinder head 16 , forms combustion chamber 20 . Cylinder head 16 is fitted with injection nozzles or injectors 22 that inject fuel into combustion chamber 20 for compression ignition therein. The cylinder head is also fitted with a glow plug 24 of known form having a heat emitting tip 26 extending into the combustion chamber 20 . Heat generating tip 26 is heated during cold engine start and low temperature operation to help ignite fuel injected into combustion chamber 20 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com