Air-conditioning heat pump device

A heat pump device and air conditioner technology, applied in the field of air conditioner heat pump devices, can solve the problems of high exhaust temperature of compressor, increase in gas content, increase in throttling loss of throttling mechanism, etc., and achieve the effects of reliable operation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

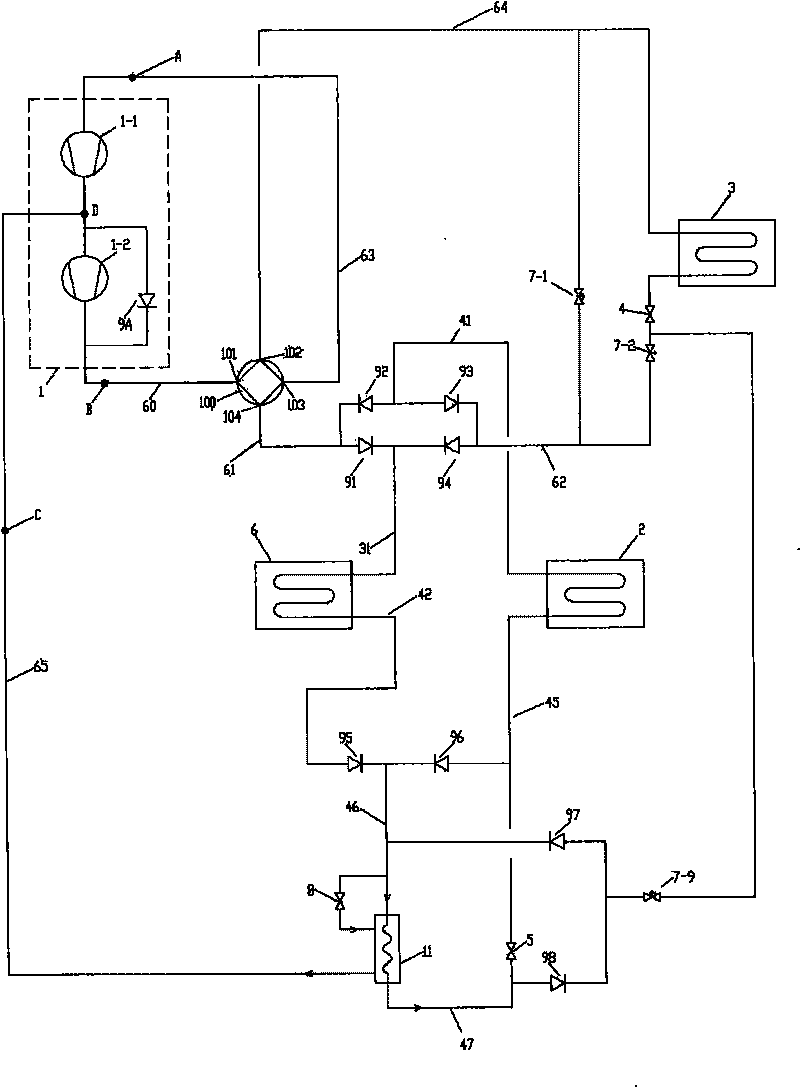

[0034] Such as figure 1 As shown, the whole device includes the following components: compression mechanism 1, heat source side heat exchanger 2, user side heat exchanger 3, second heat exchanger 6, first throttling mechanism 4, second throttling mechanism 5, four Through valve 100, first flow control valve 7-1, second flow control valve 7-2, ninth flow control valve 7-9, third throttling mechanism 8, economizer 11, first one-way valve 91, second Two one-way valves 92, the third one-way valve 93, the fourth one-way valve 94, the fifth one-way valve 95, the sixth one-way valve 96, the seventh one-way valve 97 and the eighth one-way valve 98;

[0035] The four-way valve 100 is provided with four connection nodes: 101, 102, 103, 104, each connection node is connected to two internal channels;

[0036] The compression mechanism 1 has three gas connection ports, namely: the first suction port A, the second suction port C, and the exhaust port B; Machine 1-2, the ninth one-way val...

Embodiment 2

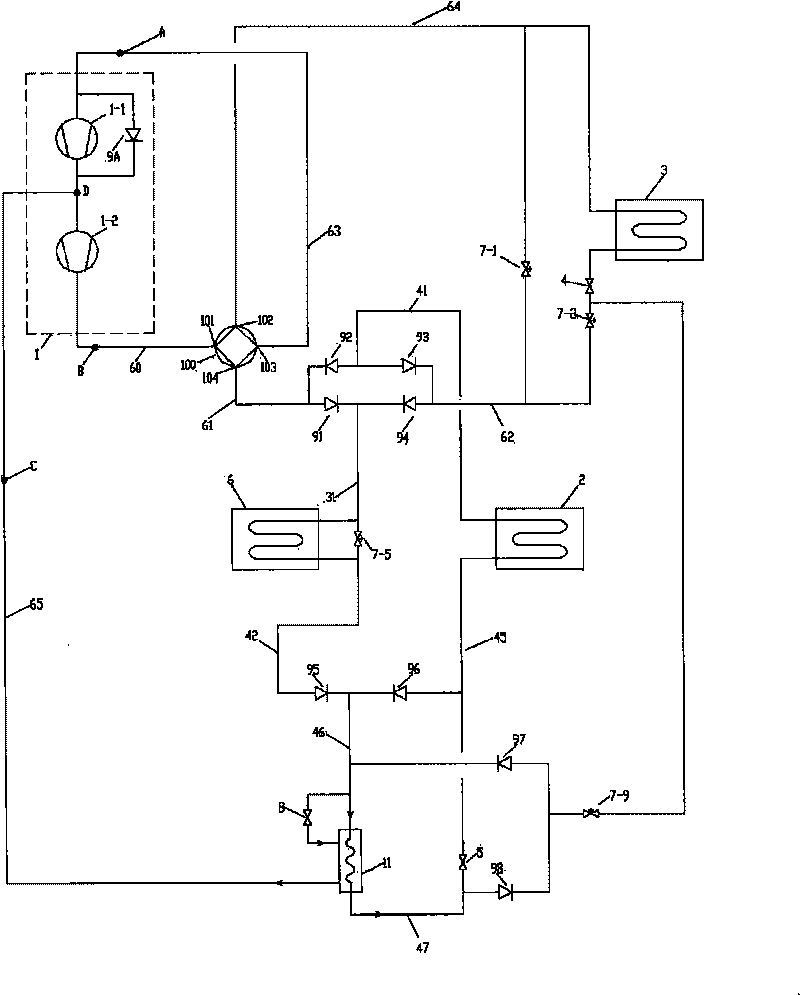

[0116] Such as figure 2 As shown, the technical solution of the compression mechanism 1 adopted in embodiment 1 also has the following variations:

[0117] The inlet port of the low-pressure compressor 1-1 is connected to the first suction port A, and the outlet port of the low-pressure compressor 1-1 passes through the inlet port of the high-pressure compressor 1-2, the outlet port of the high-pressure compressor 1-2, and the discharge port successively. The air port B is connected, the inlet port of the ninth one-way valve 9A is connected with the pipeline between the inlet port of the low-pressure compressor 1-1 and the first suction port A, and the outlet port of the ninth one-way valve 9A is connected with the low-pressure compressor 1-1. The outlet end of -1 is connected to the pipeline between the inlet end of the high-pressure compressor 1-2, and the second air suction port C is connected to the air supply port D of the compression mechanism 1;

[0118] The air suppl...

Embodiment 3

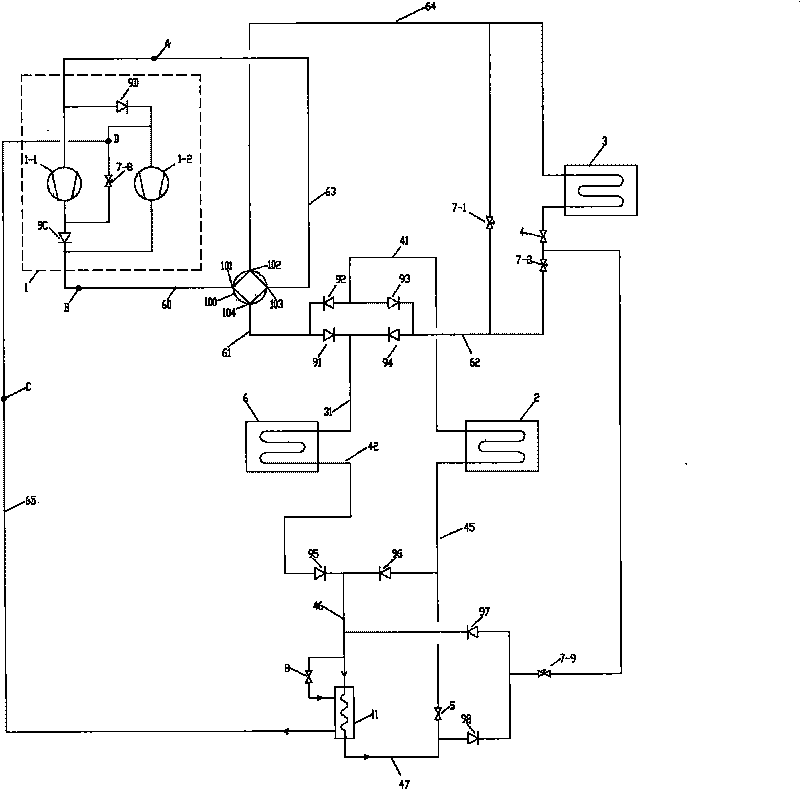

[0121] image 3 As shown, the difference between it and Embodiment 1 is that the compression mechanism 1 adopts a different technical solution, and other parts in the system are exactly the same as Embodiment 1. The compression mechanism 1 is composed of a low-pressure compressor 1-1, a high-pressure compressor 1-2, an eleventh one-way valve 9C, a twelfth one-way valve 9D, and an eighth flow control valve 7-8.

[0122]The connection scheme is as follows: the inlet port of the low-pressure compressor 1-1 is connected to the first suction port A, and the outlet port of the low-pressure compressor 1-1 passes through the inlet port of the eleventh one-way valve 9C, the eleventh one-way valve The outlet port of 9C is connected with the exhaust port B, the inlet port of the twelfth one-way valve 9D is connected with the pipeline between the first suction port A and the inlet port of the low-pressure compressor 1-1, and the outlet port of the twelfth one-way valve 9D The inlet port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com