COG chip inversion bonding device

A bonding device and chip technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unstable chip position, low chip accuracy, and impact on bonding position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

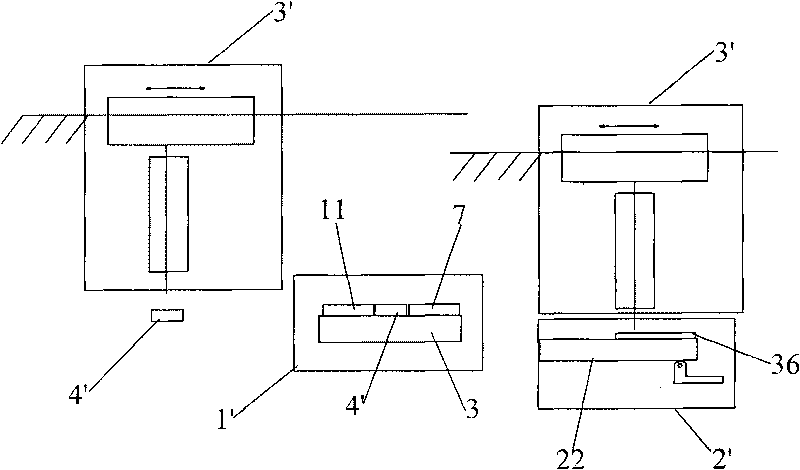

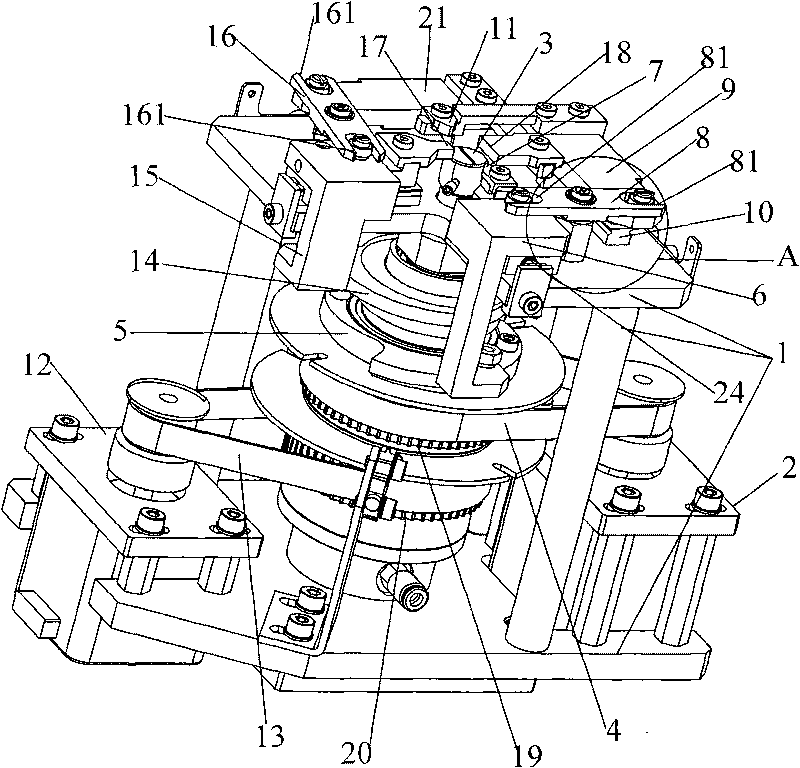

[0031] like figure 1 As shown, the present invention provides an embodiment of a COG chip flip-chip bonding device.

[0032] The COG chip flip-chip bonding device includes: a pre-calibration clamping device 1' for correcting the position of the chip, a substrate positioning device 2' for positioning the glass substrate bonded with the chip, and transporting the chip and A conveying device 3' for glass substrates, wherein the pre-calibrated clamping device 1' and the substrate positioning device 2' are fixed on the base in sequence, and the conveying device 3' is connected with the pre-calibrated clamping device 1' respectively It is connected with the driving part on the substrate positioning device 2'.

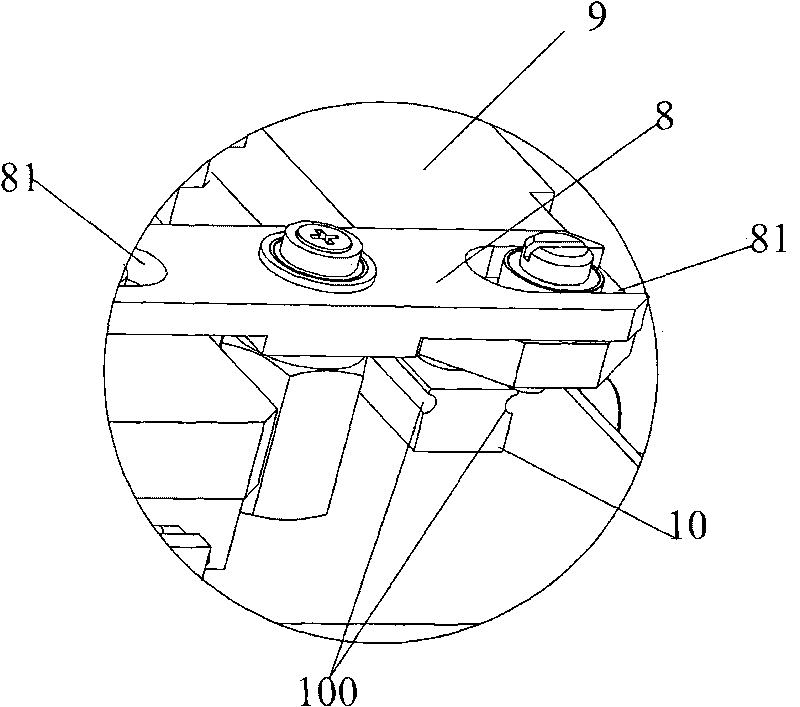

[0033] The chip 4' is transported to the fixing device 3 on the pre-calibration clamping device 1' by the conveying device 3', and is corrected in the same aspect by the first calibration block 7 and the second calibration block 11 The glass substrate 36 for bonding is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com