Product of rice grains formed by processing wheat flour and processing method thereof

A technology for processing molding and wheat flour, which is applied in the field of grain processing to achieve the effect of optimizing the quality of gluten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

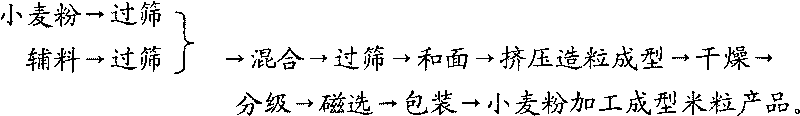

Image

Examples

Embodiment 1

[0028] Weigh the main and auxiliary raw materials that have passed through the 80-mesh sieve as follows: 70kg of wheat flour, 20kg of corn starch, and 10kg of gluten powder, put them into the dough mixer and stir for 3 to 5 minutes, then add 20kg of drinking water, and mix them in the dough. Fully stir and knead the flour in the machine to fully mix the material with water to make loose and uniform flour wet granules, and then send the wet granules into the extruder through the feeding device, and grind the material before it enters the extrusion grinding tool. For preheating, the temperature is 50-70°C; for the extrusion stage, the temperature is 100-120°C; for the curing stage, the temperature is 60-100°C. The material is extruded, and after being cut and formed in the aging section, it is dried with hot air to control the moisture content to ≤14.0%, and then it is classified and magnetically separated, and finally the finished product is packaged.

Embodiment 2

[0030] Weigh the main and auxiliary raw materials that have passed through the 80-mesh sieve as follows: 80kg of wheat flour, 13kg of corn starch, and 7kg of gluten powder, put them into the dough mixer and stir for 3 to 5 minutes, then add 26kg of drinking water, and mix them in the dough. Fully stir and knead the flour in the machine to fully mix the material with water to make loose and uniform flour wet granules, and then send the wet granules into the extruder through the feeding device, and grind the material before it enters the extrusion grinding tool. For preheating, the temperature is 50-70°C; for the extrusion section, the temperature is 100-120°C; for the curing section, the temperature is 60-100°C. The material is extruded, and after being cut and formed in the aging section, it is dried with hot air to control the moisture content to ≤14.0%, and then it is classified and magnetically separated, and finally the finished product is packaged.

Embodiment 3

[0032] Weigh the main and auxiliary raw materials that have passed through the 80-mesh sieve as follows: 85kg of wheat flour, 10kg of corn starch, and 5kg of gluten powder, put them into the dough mixer and stir for 3 to 5 minutes, then add 28kg of drinking water, and mix them in the dough. Fully stir and knead the flour in the machine to fully mix the material with water to make loose and uniform flour wet granules, and then send the wet granules into the extruder through the feeding device, and grind the material before it enters the extrusion grinding tool. For preheating, the temperature is 50-70°C; for the extrusion section, the temperature is 100-120°C; for the curing section, the temperature is 60-100°C. The material is extruded, and after being cut and formed in the aging section, it is dried with hot air to control the moisture content to ≤14.0%, and then it is classified and magnetically separated, and finally the finished product is packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com