Method for mounting wide-span cylindrical reticulated shell

A technology of cylindrical reticulated shell and installation method, which is applied in the direction of architecture and building structure, and can solve the problems of high construction cost and construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

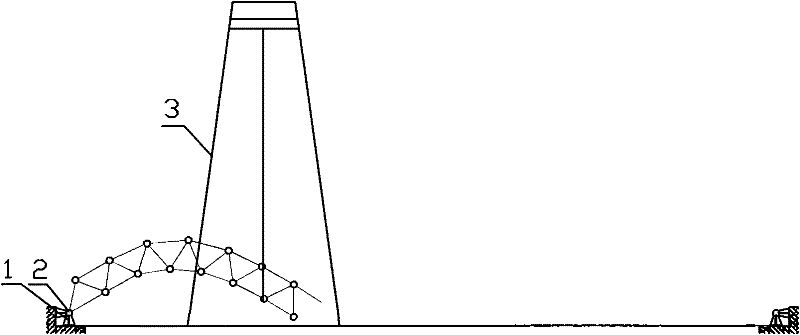

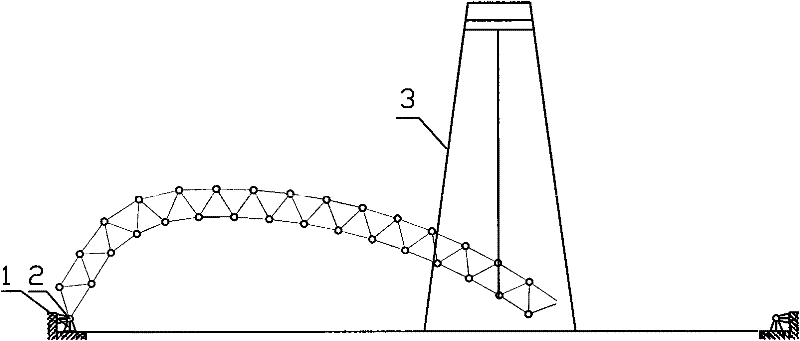

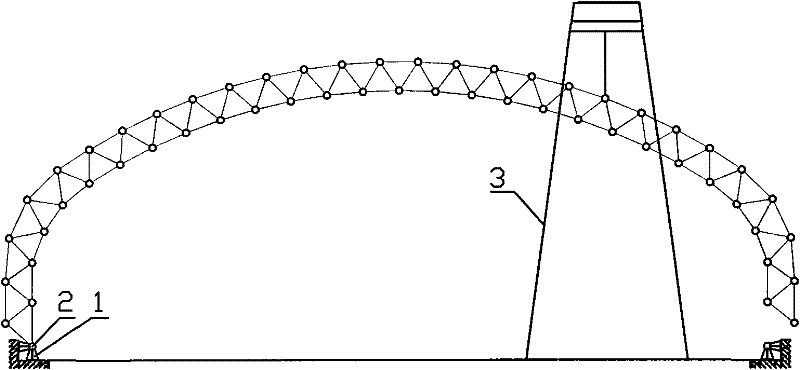

[0014] As shown in the accompanying drawings, the method for installing a large-span cylindrical reticulated shell according to the present invention is characterized in that it includes the following steps:

[0015] A) The large-span cylindrical reticulated shell is divided into multiple mesh arches arranged in the axial direction in combination with the support situation, and each mesh arch belt includes at least four supports 1 symmetrically arranged on both sides and installed on the four A support 1 is connected to each other into grid-shaped ball joints and pull rods; first a mesh arch is installed, and this first installed mesh arch is called the mother arch. Both sides of the mother arch in the present embodiment have Two bearings 1, one movable ball joint 2 is respectively installed on the bearing 1 on either side of the mother arch. The movable ball joint 2 is installed on the support 1 in a manner that can rotate and the position of the center of the ball cannot be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com