Testing method of thermal performance of partial phase change refrigeration compressor

A technology for refrigeration compressors and testing methods, which is applied in the testing of machine/structural components, pump testing, liquid variable capacity machinery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

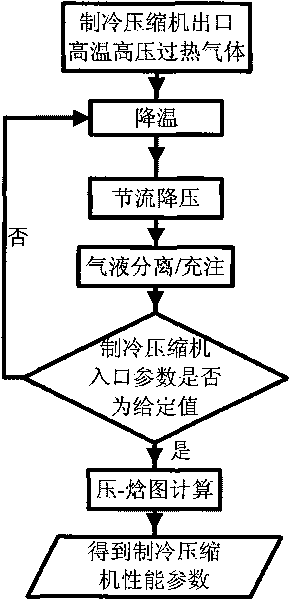

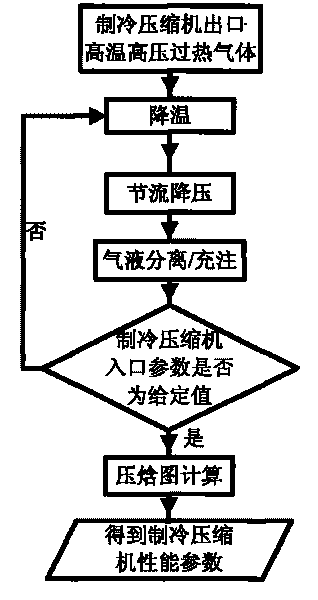

Method used

Image

Examples

Embodiment

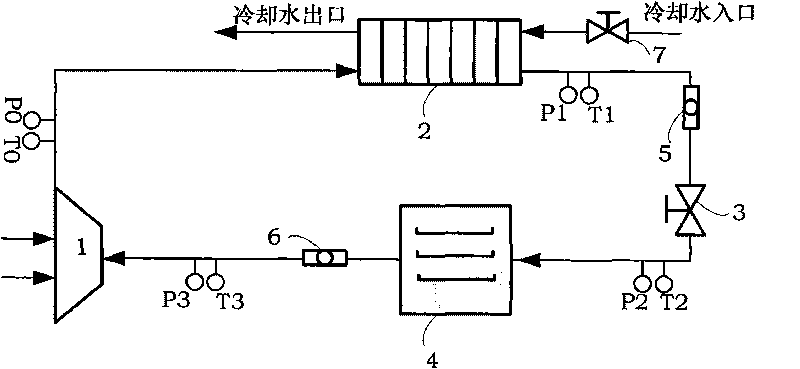

[0019] A hermetic centrifugal refrigeration compressor 1 was tested by using the test method provided by the present invention, and the refrigerant was RC318. The evaporating temperature of compressor 1 is 5°C, the condensation temperature is 55°C, and the inlet parameters of refrigeration compressor 1 after driving are pressure P3=0.156MPa and temperature T3=10°C. Such as figure 2 As shown, after being compressed by the compressor 1, the high-pressure and high-temperature gas enters the cooling stage for cooling by the condenser 2, and the cooling water in the condenser 2 cools the high-pressure and high-temperature gas into a high-pressure liquid, and the outlet pressure of the cooled high-pressure liquid is P1=0.739MPa , the temperature is T1=50°C, the high-pressure liquid is decompressed through the expansion valve 3 of the throttling and decompression link, so that its pressure is a low-pressure two-phase fluid of P2=0.156Mpa. Injection device 4, then the low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com