Process for the preparation of aldehydes

An aromatic and alkyl ester technology, applied in hydrogenolysis preparation, organic chemistry methods, chemical instruments and methods, etc., can solve the problems of expensive realization and maintenance of protective gas conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

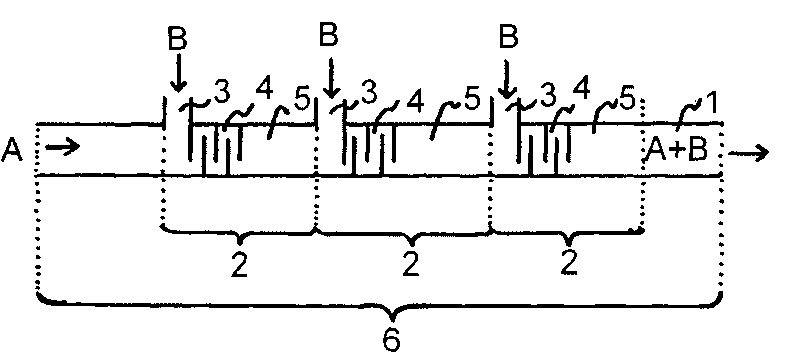

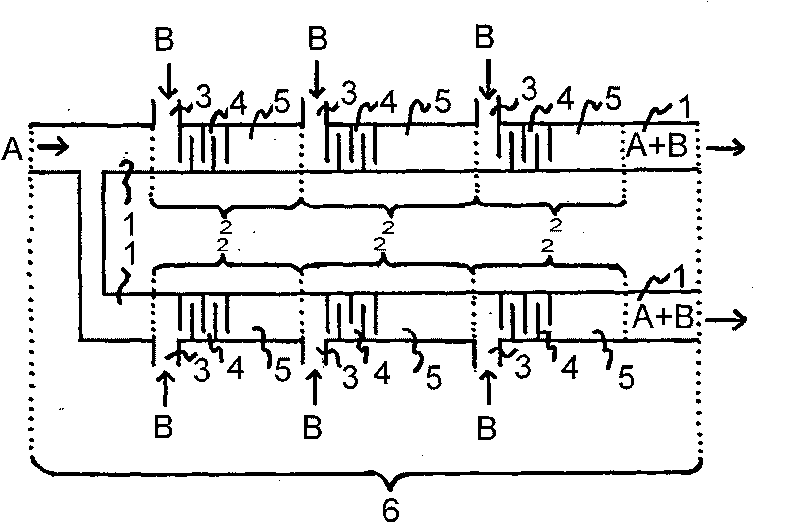

Method used

Image

Examples

Embodiment 1

[0050] The first reactant in Feed-1 was set at 2.3% by weight and the second reactant in Feed-2 was set at 24.9% by weight. The reaction temperature was set at 0°C.

Embodiment 2

[0052] The first reactant in Feed-1 was set at 10.0% by weight and the second reactant in Feed-1 was set at 24.9% by weight. The reaction temperature was set at 0°C.

Embodiment 3 to 5

[0054] The first reactant in Feed-1 was set at 2.3% by weight and the second reactant in Feed-2 was set at 24.9% by weight. The reaction temperature was set at -20°C. Different types of pumps were used in Examples 3-5 to provide Feed-1 and Feed-2.

[0055] Table 1:

[0056] implement

[0057] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com