Method for producing microporous mesoporous compound additives of cigarette filter tips

A compound additive and cigarette filter technology, which is applied to e-liquid filter elements, chemical instruments and methods, tobacco, etc., can solve the problems of complex process, reduced harmful components of cigarette smoke, high price, etc., and achieves simple process and preparation. The effect of easy control of conditions and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

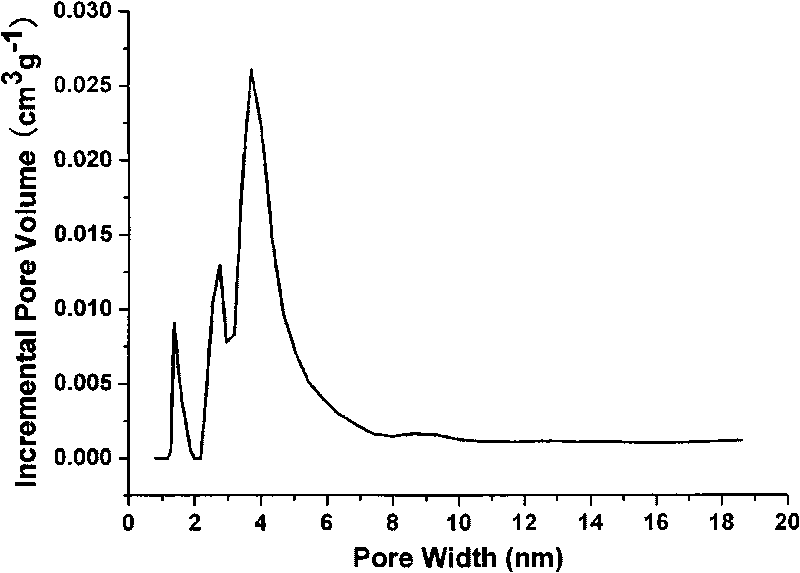

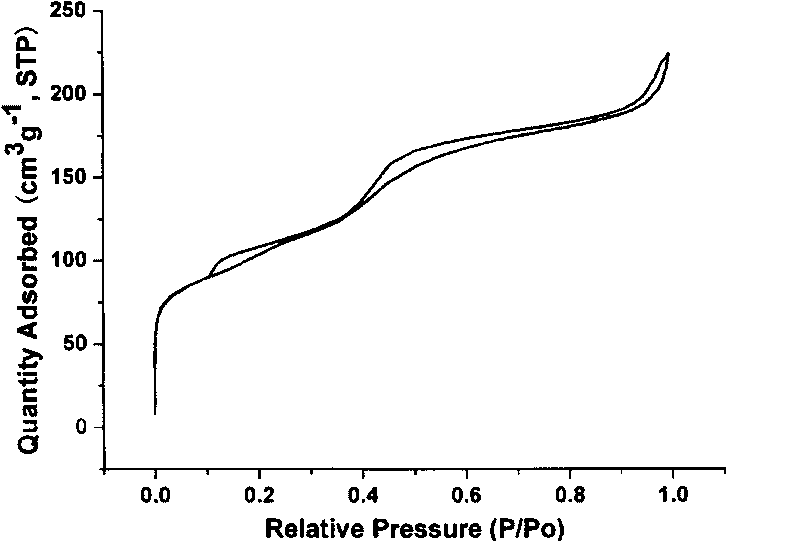

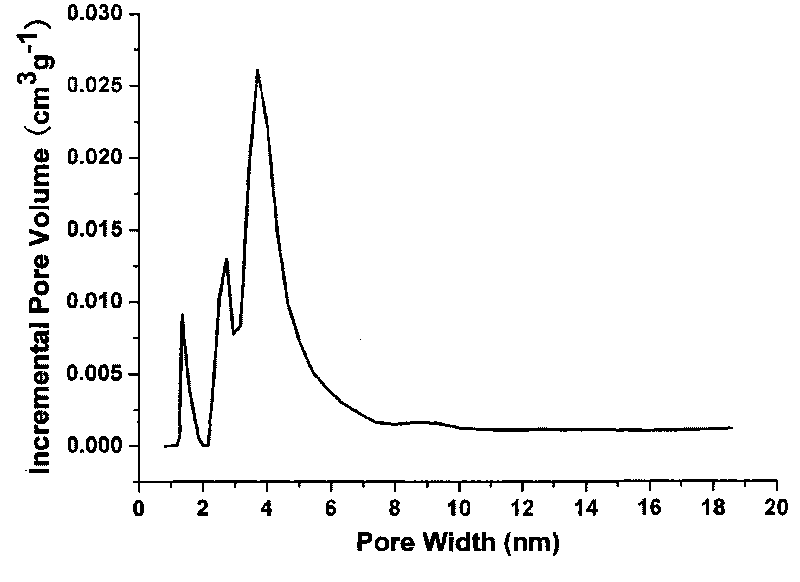

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below.

[0030] A production method of a cigarette filter microporous mesoporous composite additive, through the following steps 5 to 8:

[0031] Step 5, mixing sodium hydroxide solution, silicon source, cetyltrimethylammonium bromide (CTAB) solution as a template for synthesizing mesoporous materials, and stirring at 70°C to 90°C for 0.5 hours to 3 hours;

[0032] Step 6. Add the template tetrapropylammonium bromide (TPABr) solution of synthetic microporous materials to the above mixture, and continue to stir for 0.5 hours to 3 hours; to obtain SiO with a molar ratio of 1.0 2 : 0.065Na 2 O: CTAB of 0.045: TPABr of 0.05: H of 110 2 O mixture.

[0033] Step 7, using hydrochloric acid to adjust the pH value of the mixture obtained in step 2 to 10, transfer it to a reaction kettle, and crystallize synchronously at 165° C. for 36 hours;

[0034] Step 8. The solid precipitate obtained after synchronous crystallization is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com