Polymer-based conductive treating emulsion and method of using same

A polymer and emulsion technology, applied in the field of polymer emulsion, can solve the problems of large specific surface area, low conductive foam density, graphene drop loss, etc., and achieve the effect of excellent conductivity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

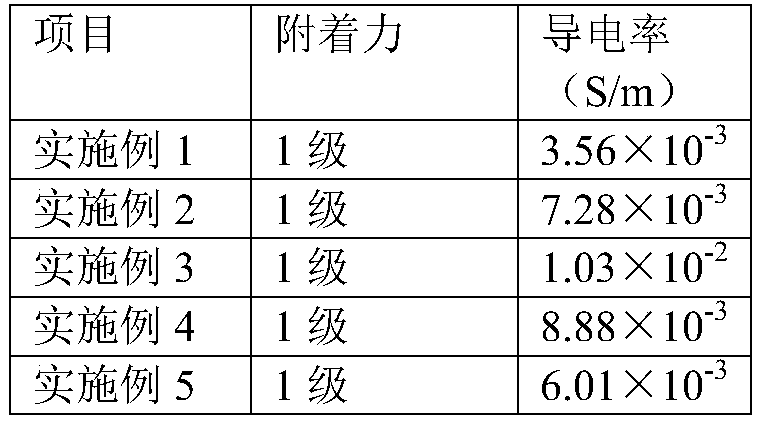

Examples

Embodiment 1

[0030] A polymer-based conductive treatment emulsion, the polymer-based conductive treatment emulsion includes the following components in parts by weight: 100 parts of epoxy hydrocarbon-based modified silicone oil, 30 parts of polysilane grafted graphene oxide, 10 parts of polyaniline 10 parts of zinc powder, 5 parts of isotridecanyl polyoxyethylene ether, 60 parts of distilled water, 3 parts of polyethylene glycol 200, 1 part of linear alkylbenzene sulfonate and 0.5 part of glacial acetic acid.

[0031] The preparation method of polysilane-grafted graphene oxide in the described polymer-based conductive treatment emulsion is as follows:

[0032] (1) Preparation of surface-modified graphene oxide: take 20 parts of graphene oxide and disperse in 100 parts of water according to parts by weight, then add a mixture of 5 parts of sodium borohydride and 3 parts of zinc powder, and stir at 50 ° C After reacting for 3 hours, add 20 parts of 5% hydrochloric acid to continue the reacti...

Embodiment 2

[0040] A polymer-based conductive treatment emulsion, the polymer-based conductive treatment emulsion includes the following components in parts by weight: 100 parts of epoxy hydrocarbon-based modified silicone oil, 45 parts of polysilane grafted graphene oxide, 20 parts of polyaniline 15 parts of zinc powder, 10 parts of fatty alcohol polyoxyethylene ether, 80 parts of distilled water, 8 parts of isopropanol, 5 parts of sodium lauryl sulfate and 3 parts of glacial acetic acid.

[0041] The preparation method of polysilane-grafted graphene oxide in the described polymer-based conductive treatment emulsion is as follows:

[0042] (1) Preparation of surface-modified graphene oxide: take 20 parts of graphene oxide in parts by weight and disperse in 100 parts of water, then add a mixture of 5 parts of sodium borohydride and 3 parts of zinc powder, and stir at 65 ° C After reacting for 3 hours, add 20 parts of 5% hydrochloric acid to continue the reaction for 1 hour, place the solu...

Embodiment 3

[0050] A polymer-based conductive treatment emulsion, the polymer-based conductive treatment emulsion includes the following components in parts by weight: 100 parts of epoxy hydrocarbon-based modified silicone oil, 35 parts of polysilane grafted graphene oxide, 15 parts of polyaniline 10 parts of zinc powder, 8 parts of alkylphenol polyoxyethylene ether, 60 parts of distilled water, 4 parts of ethylene glycol monobutyl ether, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate and 0.5 part of glacial acetic acid.

[0051] The preparation method of polysilane-grafted graphene oxide in the described polymer-based conductive treatment emulsion is as follows:

[0052] (1) Preparation of surface-modified graphene oxide: take 20 parts of graphene oxide and disperse in 100 parts of water according to parts by weight, then add a mixture of 5 parts of sodium borohydride and 3 parts of zinc powder, and stir at 55 ° C After reacting for 3 hours, add 20 parts of 5% hydrochloric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com