Metal surface treating machine

A technology of metal surface and treatment machine, which is applied to the device and coating of the surface coating liquid, which can solve the problems of scratches on the surface, unstable quality of screws or nuts or metal products, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

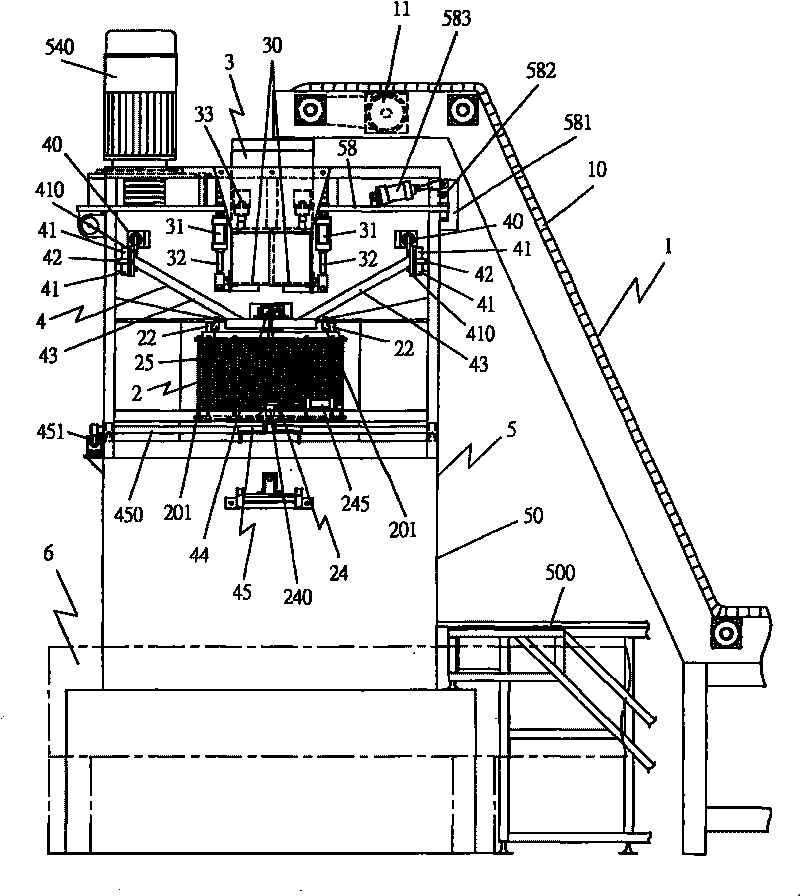

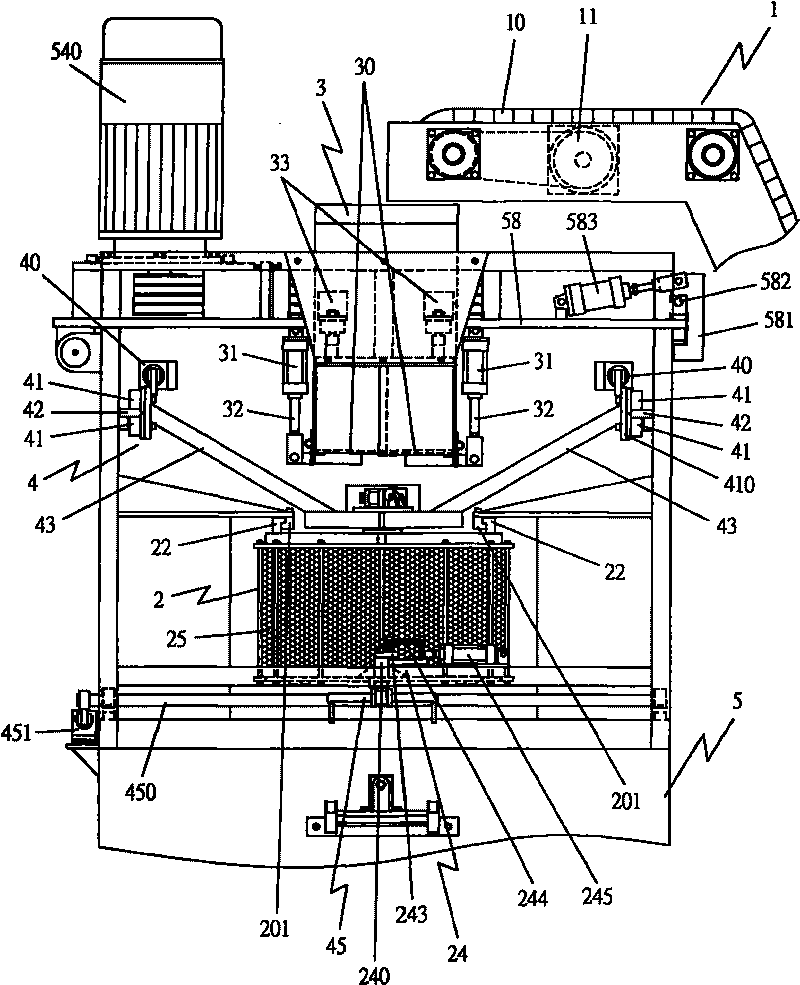

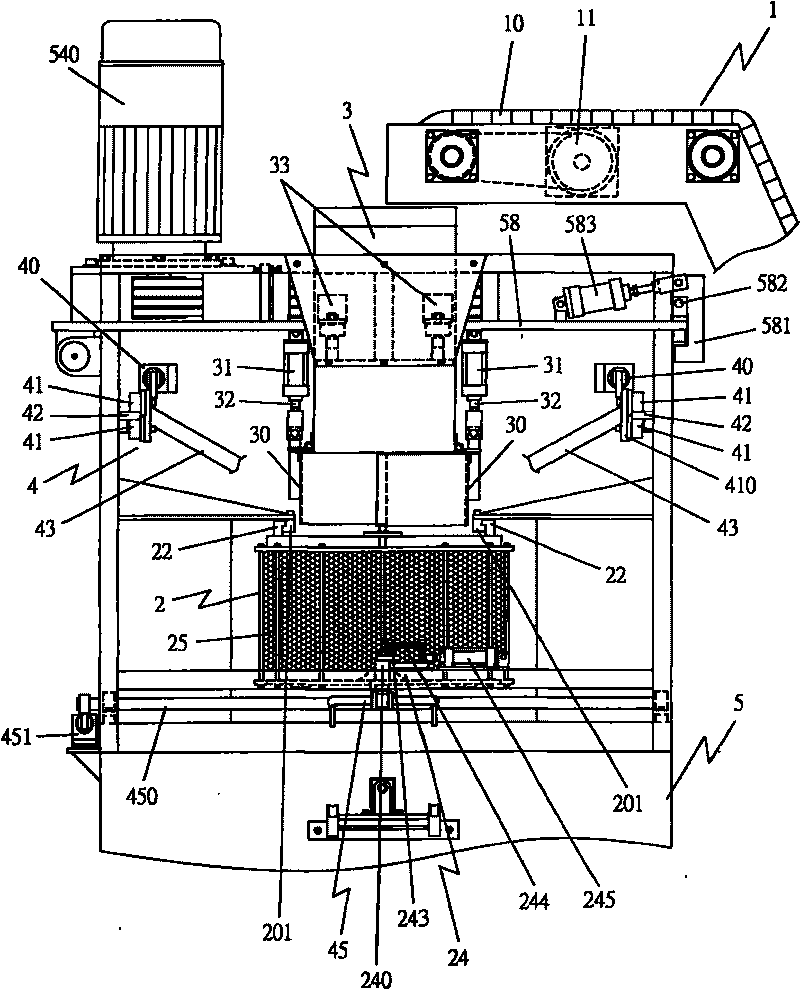

[0055] The description is as follows in conjunction with the accompanying drawings:

[0056] Such as Figure 1~3 Shown, the metal surface treatment machine of the present invention comprises:

[0057] Feeding machine 1, feeding machine 1 is equipped with a conveyor belt 10, and the conveyor belt 10 is used to transport the screws forward, and the conveyor belt 10 is driven by the transmission device 11, so that the screws or nuts to be dyed can be smoothly transported to the barrel conveyor.

[0058] Barrel conveyors such as Figure 4 and 5Shown, design barrel 2, barrel 2 has mesh barrel wall 25, so that paint or oil can enter in the barrel through mesh barrel wall 25, the work that the screw that holds in the barrel is carried out surface dipping. And barrel 2 is provided with upper and lower annular surfaces 20, 21, and two rail rods 22 and protruding columns 200 are established on upper annular surface 20, and rail groove 220 is provided on the inner side of second rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com