Centrifugal sand grain separation device and implementation method

A separation device and centrifugal technology, applied in chemical instruments and methods, solid separation, grading, etc., can solve the problems of not having the value of generalization and application, unsuitable angle and density of the screen surface, and high labor intensity, etc., to achieve The effect of simple structure, high degree of automation and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment further describe technical solution of the present invention:

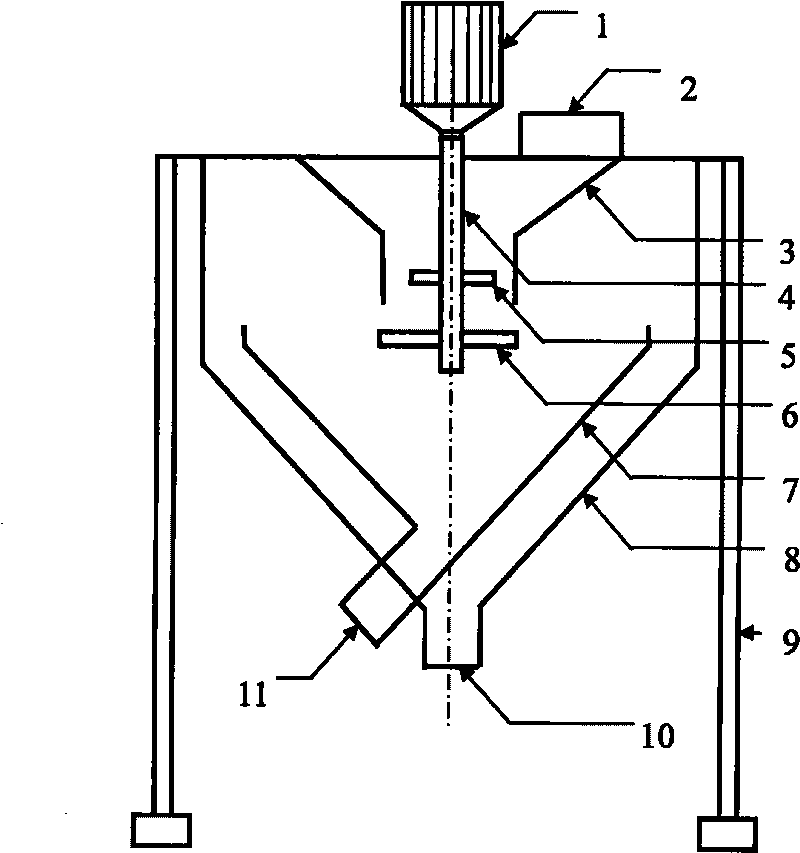

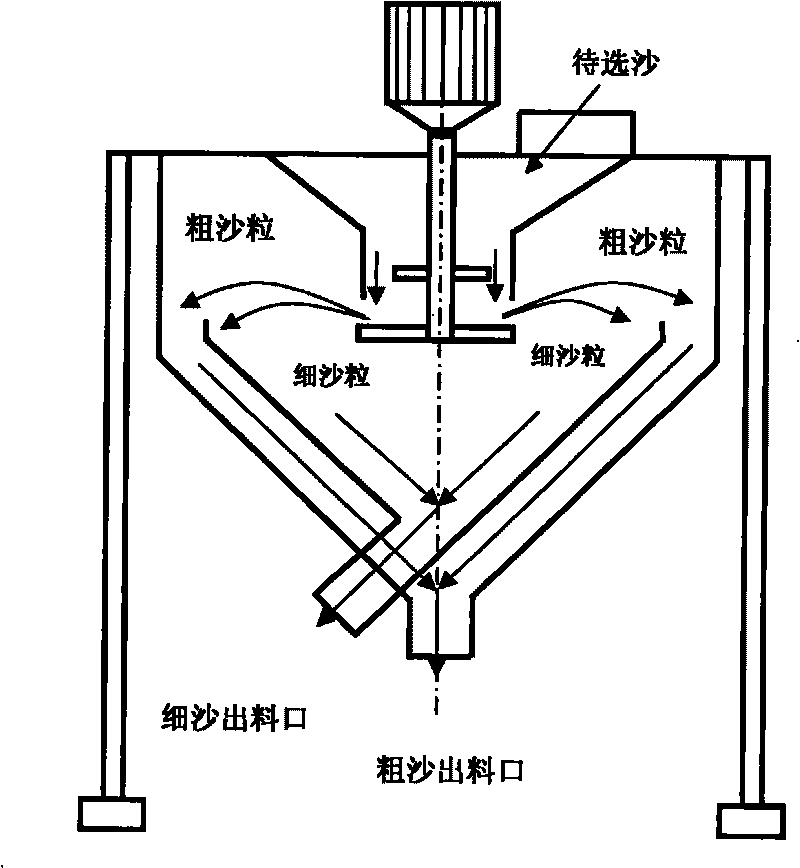

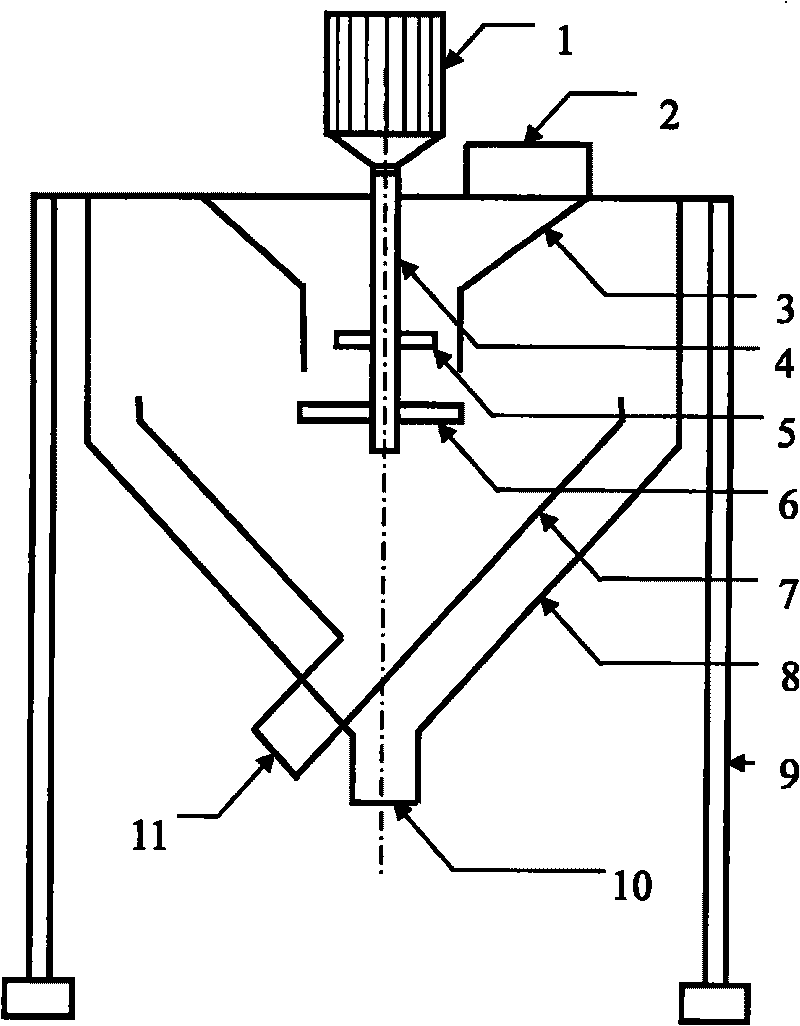

[0031] Such as figure 1 As shown, 1 speed regulating motor, 2 material inlet, 3 bulk material range controller, 4 spindle, 5 primary bulk material tray, 6 secondary bulk material tray, 7 inner cylinder, 8 outer cylinder, 9 support frame, 10 Coarse sand outlet, 11 fine sand outlets.

[0032] The motor 1 is located at the uppermost part of the centrifugal sand separation device, and the support frame 9 is connected with the outer cylinder 8; the top of the outer cylinder 8 is a whole steel plate, and a rectangular hole is opened at the position of the material inlet 2; the bulk material range controller 3 The upper part is connected with the steel plate on the top of the outer cylinder 8, and the lower part is connected with the side wall of the outer cylinder 8; the upper part of the main shaft is connected with the speed regulating motor shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com